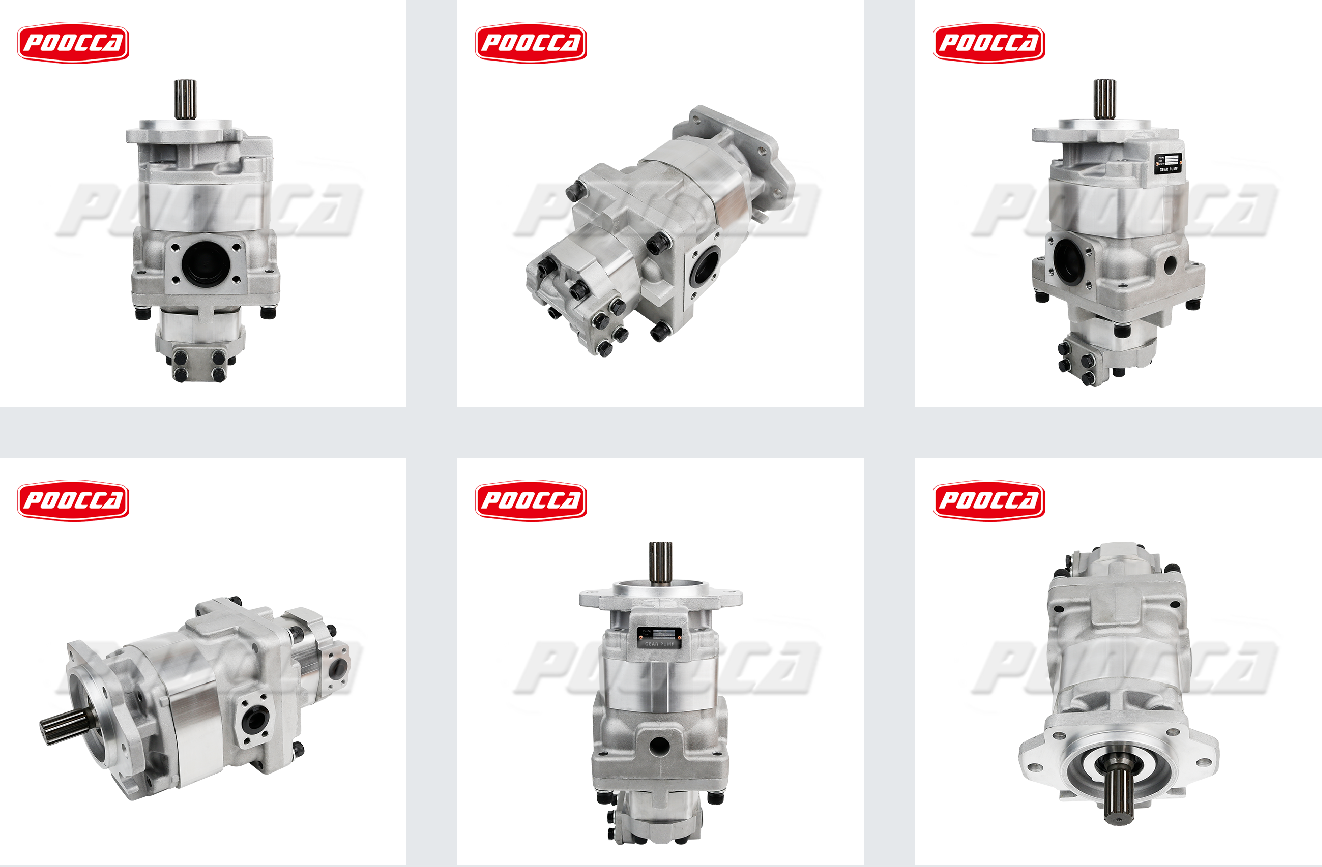

705-51-30340 Gear pump

Product Overview / Introduction

This is a heavy-duty hydraulic gear pump assembly, model 705-51-30340, designed for use in heavy equipment hydraulic systems such as cranes, bulldozers, or construction machinery.

It is manufactured with aluminum alloy housing, straight tooth external gear design, and engineered to deliver stable and pulse-free hydraulic flow.

It is often used in Crane LW250 applicationsSAL80 + 100.

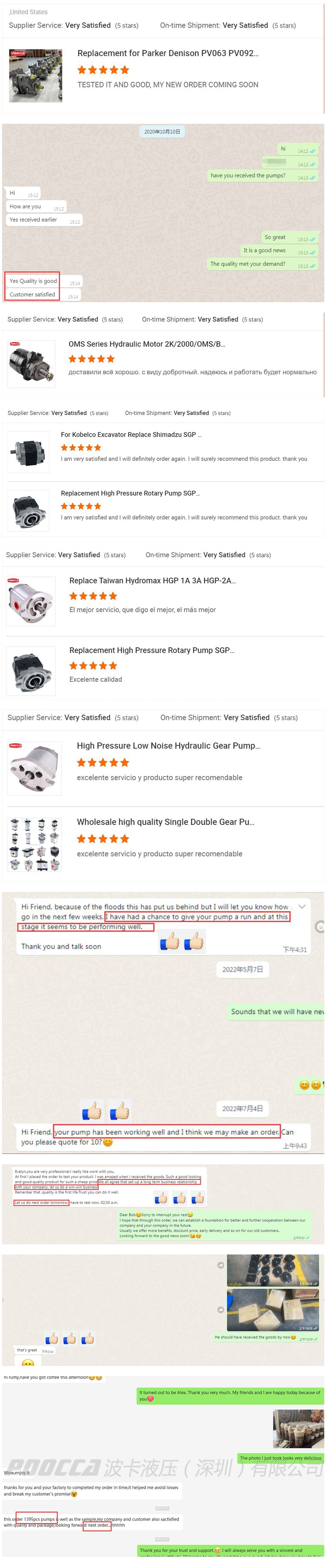

As a competent manufacturer of diversified Hydraulic Pumps, we are thriving across the globe and we are happy to share the overwhelming positive feedback we have received from satisfied customers across the globe. Our products have won accolades for their superior quality and performance. Consistent positive reviews reflect the trust and satisfaction customers experience after making a purchase.

Join our customers and experience the excellence that sets us apart. Your trust is our motivation and we look forward to exceeding your expectations with our POOCCA hydraulic pump solutions.