Brevini Oil Gear Pump OT100 OT200 OT300

| Type | Displacement( cc/rev ) | Maxworkingpressure P1( bar ) | Peakpressure P3( bar ) | Maxspeed( r.p.m) | Dimension A B | Absorbed | Code | ( Clockwise ) | |

| ( mm ) | |||||||||

| OT 100 P07 | 0.73 | 200 | 240 | 5000 | 31.30 | 64.5 | 1.8 | PS1007081S | PS1007081D |

| OT 100 P11 | 1.05 | 250 | 290 | 5000 | 31.90 | 65.6 | 2.4 | PS1007082S | PS1007082D |

| OT 100 P16 | 1.45 | 260 | 300 | 5000 | 32.75 | 67.3 | 4.2 | PS1007083S | PS1007083D |

| OT 100 P20 | 1.80 | 260 | 300 | 5000 | 33.45 | 68.7 | 5.2 | PS1007084S | PS1007084D |

| OT 100 P25 | 2.45 | 260 | 300 | 5000 | 34.50 | 70.8 | 6.7 | PS1007085S | PS1007085D |

| OT 100 P32 | 3.05 | 260 | 300 | 5000 | 35.50 | 72.8 | 8.3 | PS1007086S | PS1007086D |

| OT 100 P40 | 3.80 | 260 | 300 | 4500 | 36.90 | 75.6 | 10.1 | PS1007087S | PS1007087D |

| OT 100 P49 | 4.70 | 240 | 280 | 4500 | 38.45 | 78.7 | 12.7 | PS1007088S | PS1007088D |

| OT 100 P58 | 5.55 | 200 | 240 | 4000 | 40.00 | 81.8 | 15.0 | PS1007089S | PS1007089D |

| OT 100 P65 | 6.25 | 190 | 230 | 3750 | 41.25 | 84.3 | 16.8 | PS1007090S | PS1007090D |

| OT 100 P79 | 7.60 | 170 | 220 | 3500 | 43.60 | 89.0 | 20.5 | PS1017091S | PS1017091D |

| Type | Displacement(cc/rev ) |

Max working pressure P1 (bar ) |

Peak pressure P3 (bar ) |

Max speed (r.p.m) |

Dimension A | B |

Inlet port |

Outlet port |

|||||

| ( mm ) | 0D | 0A |

W |

0D |

0A |

W |

||||||

| OT 200 P04 | 04,10 | 250 |

300 |

4000 |

40,00 | 83,50 | 13 | 30 |

M6 |

13 | 30 |

M6 |

| OT 200 P06 | 06,20 | 250 |

300 |

3500 |

41,50 | 86,50 | 13 | 30 |

M6 |

13 | 30 |

M6 |

| OT 200 P08 | 08,20 | 250 |

300 |

3500 |

43,00 | 89,50 | 13 | 30 |

M6 |

13 | 30 |

M6 |

| OT 200 P11 | 11,20 | 250 |

300 |

3500 |

45,15 | 93,80 | 13 | 30 |

M6 |

13 | 30 |

M6 |

| OT 200 P14 | 14,00 | 240 |

300 |

3000 |

47,15 | 97,80 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| OT 200 P16 | 16,00 | 240 |

300 |

3000 |

48,60 | 100,7 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| OT 200 P20 | 20,00 | 200 |

240 |

3000 |

51,50 | 106,5 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| OT 200 P22 | 22,50 | 170 |

210 |

2500 |

57,35 | 118,2 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| OT 200 P25 | 25,10 | 170 |

210 |

2500 |

59,25 | 122,0 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| OT 200 P28 | 28,00 | 140 |

180 |

2500 |

61,35 | 126,2 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| OT 200 P30 | 30,00 | 130 |

170 |

2000 |

62,75 | 129,0 | 20 | 40 |

M8 |

13 | 30 |

M6 |

| Type | Displacement(cc/rev) |

Max working pressure P1 (bar) |

Peak pressure P3 (bar) |

Max speed (r.p.m) |

Dimension L | M |

Inlet port |

Outlet port |

|||||

| (mm) |

0D |

0A |

w |

0D | 0A | w | ||||||

| OT 300 P22 | 22 |

260 |

300 |

3000 |

57,4 |

119,3 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P2B | 28 |

260 |

300 |

3000 |

597 |

1237 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P32 | 32 |

260 |

300 |

3000 |

617 |

126,9 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P3B | 38 |

240 |

280 |

3000 |

63,5 |

131,5 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P42 | 42 |

240 |

280 |

3000 |

65.0 |

134,5 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P4B | 48 |

240 |

280 |

3000 |

72,3 |

149,1 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P53 | 53 |

220 |

250 |

3000 |

74」2 |

152,9 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P63 | 63 |

200 |

240 |

2100 |

78,0 |

160,5 |

27 |

51 |

M10 | 19 |

40 |

M8 |

| OT 300 P73/ | 73 |

180 |

210 |

2100 |

81,9 |

1682 |

36 |

62 | M12 | 27 |

51 |

M10 |

| OT 300 PB2 / | 82 |

170 |

200 |

2100 |

85,3 |

175 J |

36 |

62 | M12 | 27 |

51 |

M10 |

| OT 300 rep / | 90 |

150 |

180 | 2100 |

88,3 |

181J |

36 |

62 | M12 | 27 |

51 |

M10 |

The OT100, OT200, and OT300 gear pumps are types of positive displacement pumps that are commonly used in various applications, such as hydraulic systems, lubrication systems, and fuel transfer systems.

Here are some general characteristics of each type:

- OT100 Gear Pump:

- Flow rate: up to 100 liters per minute (LPM)

- Pressure: up to 8 bar

- Viscosity range: 10 to 200 cSt

- Temperature range: -30°C to +120°C

- OT200 Gear Pump:

- Flow rate: up to 200 LPM

- Pressure: up to 12 bar

- Viscosity range: 10 to 200 cSt

- Temperature range: -30°C to +120°C

- OT300 Gear Pump:

- Flow rate: up to 300 LPM

- Pressure: up to 10 bar

- Viscosity range: 10 to 200 cSt

- Temperature range: -30°C to +120°C

These pumps are known for their reliability, efficiency, and ease of maintenance. They are available in various materials, such as cast iron, stainless steel, and bronze, to suit different fluid compatibility requirements. Additionally, they can be configured with different port sizes and mounting options to fit specific installation needs.

Machine tools,Plastics machinery,Hydraulic presses,Construction machinery,Agriculture machinery,

Material handling equipment,Marine equipment,Mining machinery

Q: What type of fluid can be used ?

A: Designed to handle hydraulic fluids with a viscosity range of 10 to 1000 cSt (50 to 5000 SSU) at operating temperatures between -20°C and 80°C (-4°F and 176°F).

Q: What are the mounting options?

A: Can be mounted in any orientation and has a standard SAE-A 2-bolt flange mounting pattern.

Q: How long is the warranty period?

A: 12 months

Q: How is the maintained?

A: The gear pump should be regularly inspected and serviced according to the manufacturer's recommendations, which may include changing the hydraulic fluid, replacing filters, and checking for wear or damage to the pump components.

Q: What are some common applications for the OT100 OT200 OT300gear pump?

A: The OT100 gear pump is commonly used in industrial applications such as machine tools, presses, and hydraulic power units, as well as in mobile applications such as agricultural equipment, construction machinery, and material handling equipment.

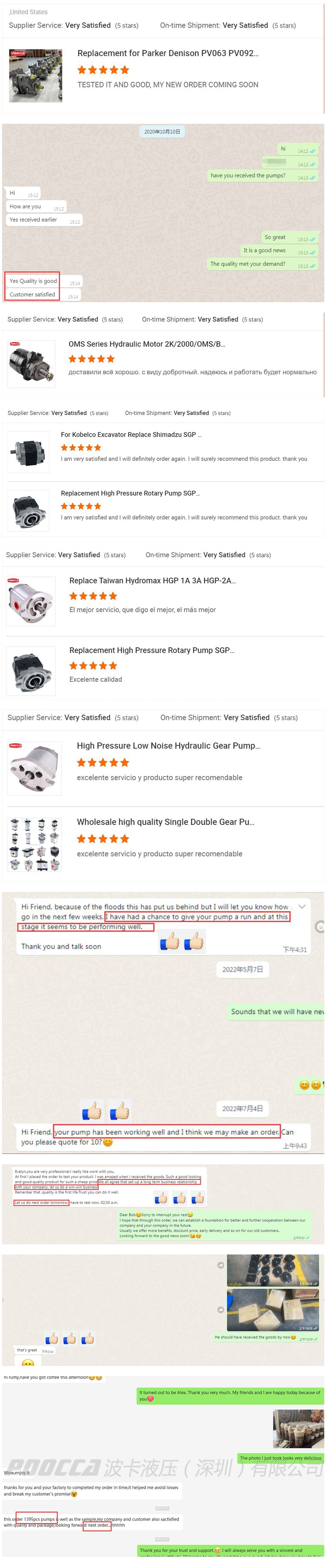

POOCCA was founded in 1997 and is a factory that integrates design,manufacturing, wholesale, sales, and maintenance of hydraulic pumps, motors, accessories, and valves. For importers, any type of hydraulic pump can be found at POOCCA.

Why are we? Here are some reasons why you should choose poocca。

√ With strong design capabilities, our team meets your unique ideas.

√ POOCCA manages the entire process from procurement to production, and our goal is to achieve zero defects in the hydraulic system.

As a competent manufacturer of diversified Hydraulic Pumps, we are thriving across the globe and we are happy to share the overwhelming positive feedback we have received from satisfied customers across the globe. Our products have won accolades for their superior quality and performance. Consistent positive reviews reflect the trust and satisfaction customers experience after making a purchase.

Join our customers and experience the excellence that sets us apart. Your trust is our motivation and we look forward to exceeding your expectations with our POOCCA hydraulic pump solutions.