When engineers and equipment buyers search for “the simplest hydraulic pump”, they are usually focused on more than just academic definitions — they want real answers about cost, maintainability, reliability, and practical performance in real-world systems. Hydraulic pumps are the heart of any fluid power system, converting mechanical energy into hydraulic energy to drive actuators, cylinders, motors, and other components. Among the many types of pumps available, identifying the simplest one requires a clear definition of simplicity and an understanding of how different designs compare in structure, operation, and application.

Traditionally, gear pumps are regarded as the simplest type of hydraulic pump due to their minimal moving parts and straightforward operating principle. However, “simple” does not automatically mean “best” for every application. This article will explain why gear pumps earn that reputation, how they compare to vane and piston pumps, and how to choose the right pump for your needs based on performance, cost, and maintenance considerations.

What Makes a Hydraulic Pump “Simple”?

To objectively answer which hydraulic pump is the simplest, we first need to define what “simplicity” means in the context of hydraulic pump design and application. In hydraulic systems, a pump’s simplicity is typically evaluated based on mechanical complexity, number of moving parts, ease of maintenance, and manufacturing cost. These factors directly influence reliability, serviceability, and total ownership cost — core concerns for engineers and buyers evaluating hydraulic components.

1. Simplicity Defined

A simple hydraulic pump generally has:

-

Fewer moving parts: Less potential for mechanical failure.

-

Straightforward operating principle: Easier to understand, install, and troubleshoot.

-

Low manufacturing and maintenance costs: Reduces long-term system expenses.

-

Robust performance under typical conditions: Tolerant to contamination and wide operating environments.

In engineering practice, these traits matter because they affect downtime, service intervals, spare part requirements, and lifecycle cost — all key factors when specifying hydraulic pumps for industrial or mobile machinery.

2. Gear Pumps: The Benchmark for Simplicity

Among the major hydraulic pump types — gear, vane, and piston pumps — gear pumps consistently score highest on simplicity:

-

Minimal moving parts: Gear pumps rely primarily on two interlocking gears and a casing to trap and move fluid, making their design inherently straightforward.

-

Fixed displacement operation: They deliver a constant amount of fluid per revolution without the need for complex internal controls.

-

Ease of maintenance: With fewer internal components, gear pumps are easier and cheaper to repair or rebuild compared with more complex pump types.

-

Simple manufacturing: Gear pumps are cost-effective to produce due to basic gear machining and uncomplicated housing.

These traits help explain why gear pumps are the most widely used hydraulic pump type in many low-to-medium pressure systems — especially when cost, durability, and simplicity outweigh the need for variable flow control or ultra-high pressures.

3. Simplicity Compared to Other Pump Types

While gear pumps exemplify mechanical simplicity, other pumps bring additional functionality at the cost of complexity:

-

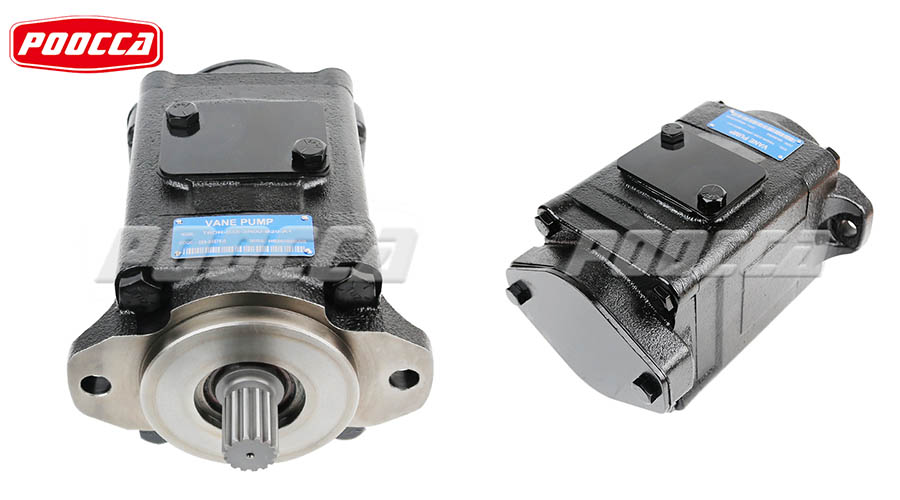

Vane Pumps: These use sliding vanes within a rotor and can offer smoother flow and quieter operation, but they have more internal components and are more sensitive to fluid contamination.

-

Piston Pumps: Piston pumps — especially variable displacement designs — contain numerous pistons, swashplates, or cam mechanisms that enable high pressures and adjustable flow, but add significant mechanical complexity and higher precision requirements.

In practical terms, the simplest pump design means less to go wrong, easier maintenance, and lower upfront cost — all reasons why gear pumps are often the first choice for straightforward hydraulic systems where performance requirements fall within their operating range.

Why Gear Pumps Are the Simplest

When comparing hydraulic pumps, gear pumps stand out for their simplicity — a quality rooted in their straightforward mechanical design and ease of use. A gear pump moves fluid by trapping it between the teeth of meshing gears and the pump housing, pushing it from the inlet to the outlet as the gears rotate.

1. Minimal Moving Parts and Simple Construction

The core of a gear pump consists of just two interlocking gears, a casing, and basic seals. Unlike vane pumps that require sliding vanes and springs, or piston pumps with swashplates and multiple pistons, gear pumps keep mechanics basic. This leads to:

-

Fewer components to wear or fail

-

Easier assembly and repair

-

Lower manufacturing cost

All of these contribute to simplicity in both design and maintenance.

2. Predictable, Fixed Displacement Operation

Gear pumps typically operate as fixed-displacement positive-displacement pumps, meaning the output flow is directly proportional to rotational speed. There are no internal adjustments or complex controls needed to regulate displacement — you simply vary the speed to change flow. This predictability reduces system complexity and simplifies control design.

3. Compact Size and High Reliability

Because gear pumps don’t need complex internal mechanisms, they are compact, lightweight, and robust. Their simple layout also gives them a reliable operational profile in many industrial and mobile systems that do not require advanced flow modulation.

4. Self-Priming and Broad Viscosity Tolerance

Many gear pumps are self-priming, which means they can draw fluid into the pump chamber without pre-filling, simplifying system startup and installation. Additionally, they handle a wide range of fluid viscosities effectively, especially oils and hydraulic fluids, further widening their application without added design complexity.

Comparison & Practical Buying Guidance

Hydraulic Pump Comparison (Key Metrics)

| Feature | Gear Pump | Vane Pump | Piston Pump |

|---|---|---|---|

| Structure Complexity | Very simple – few parts | Medium – vanes + rotor + cam ring | Complex – pistons, swash plates, valves |

| Moving Parts | Fewest | Moderate | Most |

| Maintenance Ease | Easy and inexpensive | Moderate | Difficult and costly |

| Typical Pressure Range | Low-to-medium | Medium | Medium-to-high |

| Flow Smoothness | Some pulsation | Smoother | Very smooth |

| Noise Level | Higher | Lower | Moderate |

| Efficiency | Moderate | Higher than gear | Highest (especially variable) |

| Cost | Lowest | Medium | Highest |

When Simplicity Is Not Enough

While gear pumps win on simplicity, there are engineering scenarios where other pump types are more appropriate:

Vane Pumps (Balanced Performance)

-

Smoother flow and lower noise: Ideal for systems where vibration and sound are concerns.

-

Moderate efficiency and pressure: Suited for mobile and industrial applications with steady loads.

-

More complex than gear pumps: Slightly higher maintenance and cost.

Piston Pumps (High Performance)

-

High pressures and adjustable flow: Excellent for precision systems and heavy machinery.

-

Best efficiency: Especially with variable displacement designs.

-

Most complex and costly: Higher initial cost and maintenance needs.

Practical Buying Guidelines (Expert POV)

Here’s a step-by-step framework to match your system needs with the right pump type:

-

Define Your Pressure Range

-

Low to moderate (<250–300 bar): Gear pumps are typically sufficient.

-

Medium and smooth flow required: Consider vane pumps.

-

High pressures or variable flow needs: Piston pumps are the best choice.

-

-

Determine Flow Requirements

-

Steady, basic flow: Fixed-displacement gear pumps excel.

-

Controlled or adaptive flow: Variable pumps (often piston or advanced vane) perform better.

-

-

Assess Maintenance & Life

-

Gear pumps often have lowest total cost of ownership due to simplicity and spare parts availability.

-

Piston pumps, while expensive, may save energy and extend lifespan in high-demand systems.

-

-

Match to Environment & Fluids

-

Gear pumps are generally tolerant of dirty or viscous fluids, reducing filtration costs.

-

Piston and vane pumps require cleaner media and better filtration.

-

Typical Application Scenarios for Simple Hydraulic Pumps

1. Light & Medium Duty Hydraulic Systems

Gear pumps excel in agriculture equipment (tractors, sprayers), forklifts, and basic industrial machines where low‑to‑medium pressure and consistent flow are required. Their robust design and low cost make them a preferred choice in these environments.

2. Mobile Machinery & Construction Equipment

In many construction machines (e.g., loaders and backhoes), simplicity and reliability are key. Gear pumps provide a steady, predictable flow with less frequent maintenance — ideal for harsh mobile applications.

3. Fixed Displacement Systems

Systems that don’t require flow variation — such as lubrication circuits, basic hydraulic presses, and fixed‑rate actuators — benefit from gear pumps’ fixed displacement characteristic.

4. Applications With Less Demanding Pressure Needs

If your system operates mostly in low‑to‑medium pressure ranges (e.g., under ~250 bar), the simplicity and cost‑effectiveness of gear pumps often outweigh the advantages of more complex pumps.

Common Misconceptions About “Simple” Hydraulic Pumps

1. Gear Pumps Can Only Rotate in One Direction

Another common misconception is that gear pumps are limited to clockwise or counterclockwise rotation. In fact, they can be designed for either rotation, and changing the rotation simply changes the flow direction — not the pump’s overall performance.

2. Simpler Means Inferior Performance

It’s easy to assume that a “simple” pump must be less capable. While gear pumps generally perform well in low‑to‑medium pressure systems, their simplicity often results in high reliability and low maintenance, not low performance — provided they are matched correctly to the application.

3. All Simple Pumps Are Good for High Pressure

Some think simplicity equals suitability at any pressure level. In fact, pumps with fewer moving parts (like gear pumps) are not always ideal for high pressure or highly variable flow systems — those applications may favor vane or piston designs for efficiency and precision.

Conclusion & Call to Action

In the context of hydraulic systems, simplicity isn’t just a buzzword — it reflects how easy a pump is to build, operate, maintain, and service, all of which directly impact lifecycle cost, downtime, and total ownership. Based on industry standards and technical comparisons:

Gear Pumps Are the Simplest Hydraulic Pump Type

-

Mechanically basic: Gear pumps use just two meshing gears to move fluid, making their internal structure straightforward and robust.

-

Fewer moving parts: With minimal components compared to vane and piston pumps, there are fewer points of failure and simpler maintenance.

-

Low maintenance and cost: Their design leads to lower manufacturing cost and easier, faster repairs — ideal for general industrial and mobile applications.

-

Broad application range: From construction equipment to agricultural systems, gear pumps offer simplicity without sacrificing essential performance in many low-to-medium pressure systems.

Remember the Trade-offs

While gear pumps lead on simplicity, they aren’t always the best fit for every system:

-

Noise and flow pulsation: Their simple design can result in more noise and less smooth flow than vane pumps.

-

Fixed displacement: Most gear pumps lack variable displacement, limiting adaptability in systems needing precise flow control.

-

Efficiency limits: Gear pumps generally show lower volumetric efficiency than vane or piston pumps in certain operating conditions.

This means simplicity should be balanced with your performance requirements. If your system needs quiet operation or variable flow, a vane pump might be preferred. For high-pressure and highly controlled systems, piston pumps deliver superior efficiency and precision — even if they are more complex and costly.

Ready to Choose the Best Pump for Your System?

At Poocca Hydraulic Manufacturer, we’ve spent over 20 years designing and supplying reliable hydraulic pumps optimized for simplicity, durability, and performance. Whether you need:

-

Cost-effective gear pumps for light to medium duty systems,

-

Balanced vane pumps for smoother flow, or

-

High-performance piston pumps for demanding industrial applications —

we can help match the right pump to your specific needs.

Contact our experts today for personalized pump selection, technical consultation, and a quote tailored to your application. Let Poocca help you build hydraulic systems that are both simple and smart.

Post time: Jan-13-2026