In hydraulics, the heart of any system lies in its pump. Choosing the right pump can make or break the efficiency and performance of your hydraulic system. Among the many types of pumps, there is one that dominates most hydraulic systems – the hydraulic gear pump. Because of its reliability, simplicity and versatility, it has become the first choice for a variety of applications, from heavy machinery to industrial processes.

The role of pumps in hydraulic systems

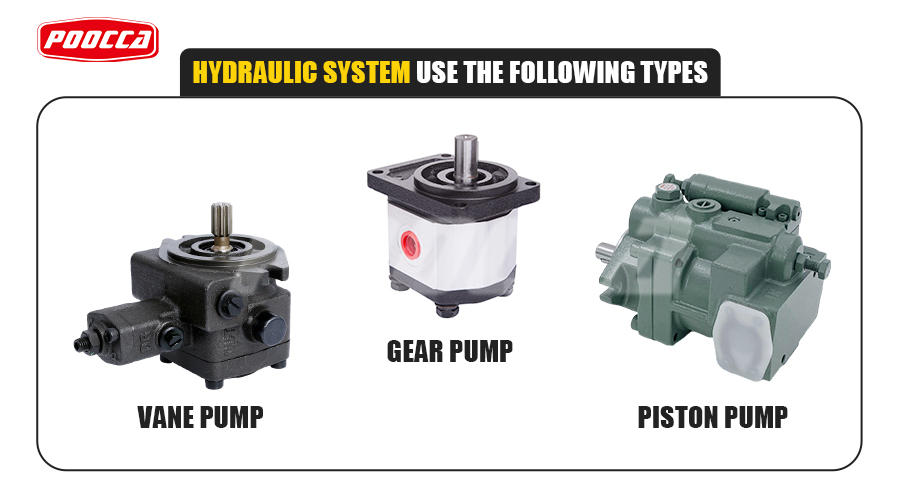

Hydraulic systems are used in many industries including construction, agriculture, manufacturing and aerospace due to their ability to efficiently transmit power through fluids. Pumps play a key role in these systems by converting mechanical energy into hydraulic energy, providing the force and motion needed to operate various components such as cylinders, motors and valves.

Hydraulic gear pump

Among the different types of hydraulic pumps, hydraulic gear pumps are the most popular. Its popularity can be attributed to several key features and benefits.

Simple and Reliable: Hydraulic gear pumps are known for their simple design, consisting of just two gears that mesh together to form a suction and discharge chamber. This design minimizes the possibility of mechanical failure, making the gear pump highly reliable. Their simple construction means they are easier to maintain and repair, so they are widely used in industries where downtime is costly.

Efficiency: Hydraulic gear pumps are known for their high volumetric efficiency. This means they provide consistent and predictable hydraulic oil flow, even with pressure changes. They excel at maintaining a constant flow rate, which is critical for accuracy in many applications.

Compact Size: Hydraulic gear pumps are relatively compact and lightweight compared to some other pump types. This makes them suitable for applications with limited space or weight constraints, such as mobile devices and aircraft.

Versatility: Hydraulic gear pumps are well suited to a variety of hydraulic oil viscosities, allowing them to adapt to a variety of operating conditions. They can handle both low and high viscosity fluids, and this versatility is a significant advantage in industries with different requirements.

Cost-Effectiveness: Hydraulic gear pumps are relatively cheap to manufacture compared to other types, making them an attractive option for many applications, especially in industries where cost-effectiveness is critical.

Low Noise: Another notable feature of gear pumps is their quiet operation. Their meshing gears produce less noise than some other pump types, which is a significant advantage in environments where noise levels need to be minimized.

Applications of hydraulic gear pumps

Hydraulic gear pumps are used in a wide variety of applications:

Construction machinery: Excavators, bulldozers and cranes often rely on hydraulic gear pumps to provide the power needed to dig, lift and move heavy loads.

Farm Equipment: Tractors, combines, and other farm machinery use hydraulic gear pumps to operate various implements and systems, such as steering, lift, and power take-offs.

Manufacturing equipment: Hydraulic presses, injection molding machines and metal forming equipment rely on hydraulic gear pumps for precise control and high force output.

Aerospace industry: Aircraft hydraulic systems use gear pumps to implement functions such as landing gear telescopic, flap control and braking systems.

Automotive industry: Hydraulic gear pumps can be used in power steering systems to help drivers turn the wheels smoothly.

Industrial Automation: Hydraulic gear pumps are used in a variety of industrial automation applications such as conveyors and material handling systems.

Marine applications: Marine and offshore equipment rely on hydraulic gear pumps for tasks such as winch operation, cargo handling and steering control.

The future of hydraulic gear pumps

As the industry continues to evolve and require more efficient and sustainable solutions, hydraulic gear pumps are not immune to innovation. Continuous research and development focuses on improving the performance, reliability and environmental friendliness of gear pumps. This includes efforts to improve the overall efficiency of hydraulic systems, reduce energy consumption and reduce the environmental impact of hydraulic fluids.

Post time: Oct-17-2023