In hydraulic power systems, radial piston pumps and axial piston pumps are two core technologies, occupying different application fields with their unique structural design and performance characteristics. Although both realize fluid pressure energy conversion through the reciprocating motion of the piston, there are significant differences in their internal structure, working characteristics and applicable scenarios.

Core structural differences: “radial” and “parallel” arrangement of pistons

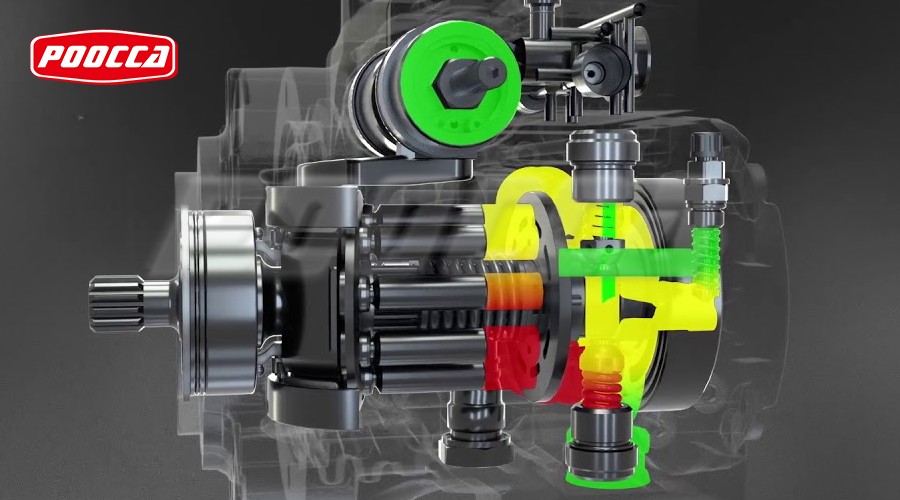

1. Hydraulic radial piston pump: the pistons are radially distributed

Structural features: The pistons are arranged in a star shape along the radial direction of the drive shaft (similar to wheel spokes), perpendicular to the main shaft.

Working principle: The piston is close to the eccentric cam ring (Cam Ring) through centrifugal force or mechanical push. As the rotor rotates, the piston reciprocates in the radial hole to complete the oil suction and oil pressure process.

Key components: eccentric cam ring, rotor cylinder, distribution shaft.

2. Hydraulic axial piston pump: the piston is arranged parallel to the main shaft

Structural features: The piston is parallel to the drive shaft and evenly distributed in the rotating cylinder.

Working principle: The plunger achieves reciprocating motion through the inclination angle of the swashplate or bent axis. The larger the swashplate angle, the longer the plunger stroke and the higher the output flow.

Key components: swashplate/bent axis, rotating cylinder, distributor plate.

Visual comparison:

Radial pump: The structure is more “robust”, suitable for ultra-high pressure, but the volume is larger.

Axial pump: The structure is more “compact”, suitable for high speed, variable control, and has higher power density.

Performance comparison: pressure, efficiency, life and noise

1. Pressure capacity

Radial piston pump: Designed for ultra-high pressure (above 600-1000 bar), such as hydraulic presses, deep-sea equipment and other extreme working conditions.

Axial piston pump: The mainstream pressure range is 200-450 bar, and some high-end models can reach 600 bar, suitable for construction machinery, injection molding machines, etc.

Conclusion: If the system pressure demand exceeds 500 bar, the radial pump is the only choice; if it is below 400 bar, the axial pump is more cost-effective.

2. Flow stability and noise

Radial pump: fewer plungers (usually 5-7), larger flow pulsation, higher noise (above 80 dB).

Axial pump: more plungers (7-9 or more), smoother flow output, lower noise (70-75 dB).

Application impact: Axial pumps are preferred for noise-sensitive scenarios (such as medical equipment and precision machine tools).

3. Efficiency and variable control

Radial pump:

High mechanical efficiency (92%+), but complex variable adjustment, cam eccentricity adjustment, slow response.

Suitable for fixed displacement or low-speed and high-pressure conditions.

Axial pump:

High volumetric efficiency (95%+), flexible variable control (by adjusting the angle of the swash plate), and fast response.

Suitable for variable frequency speed regulation and energy-saving systems (such as excavators and wind power variable pitch systems).

4. Life and maintenance

Radial pump: simple structure, strong pollution resistance, suitable for harsh environments (such as mining machinery).

Axial pump: The swash plate and plunger pair have high requirements for oil cleanliness and require fine filtration (NAS 1638 Class 6 or above).

Comparison of typical application scenarios

1. The main battlefield of radial piston pumps

Ultra-high pressure hydraulic system:

Metal forming (hydraulic press, forging press)

Deep-sea equipment (ROV hydraulic power)

Military industry (submarine hydraulic system)

Extreme environment:

Mining machinery (pollution resistance, impact resistance)

Oil drilling (high-pressure mud pump)

2. The dominant field of axial piston pumps

Mobile hydraulic equipment:

Construction machinery (excavator, loader)

Agricultural machinery (combine harvester)

Industrial automation:

Injection molding machine, die-casting machine

Wind power variable pitch system

Aerospace:

Aircraft landing gear hydraulic system

Market trends and future development directions

1. Technological breakthroughs of axial pumps

Higher pressure: Some manufacturers (such as Bosch Rexroth and Parker Hannifin) have launched 600 bar axial pumps to challenge the traditional advantages of radial pumps.

Intelligent control: integrated sensors to achieve real-time adjustment of flow and pressure (IoT hydraulic system).

2. Irreplaceability of radial pumps

The 1000 bar+ market is still dominated by radial pumps, such as ultra-high pressure water cutting and special metallurgical equipment.

Material progress: ceramic plungers and carbon fiber reinforced shells increase life.

3. Environmental protection and energy efficiency requirements drive innovation

Axial pumps are more in line with the energy-saving needs under the “dual carbon” goal due to their high-efficiency variable characteristics.

Radial pumps have found new growth points in renewable energy (such as tidal power generation hydraulic systems).

Radial piston pumps and axial piston pumps represent two philosophies of hydraulic technology:

Radial pumps are “power players” designed for ultra-high pressure and high reliability scenarios;

Axial pumps are “all-round players” with better efficiency, controllability and compactness.

If you have any needs, please contact poocca hydraulic manufacturer.

Post time: Jun-10-2025