In the modern hydraulic industry, choosing the right pump type can significantly impact system efficiency, energy consumption, and overall lifespan. The most commonly used positive displacement pumps are vane pumps and gear pumps. While both are fundamental to fluid power systems, they work differently and are suited to different applications.

This article was written by Poocca Hydraulic to provide an expert comparison of vane and gear pumps to help engineers, purchasing managers, and hydraulic system integrators make informed purchasing decisions.

1. Working Principle: How They Work

Hydraulic Vane Pumps:

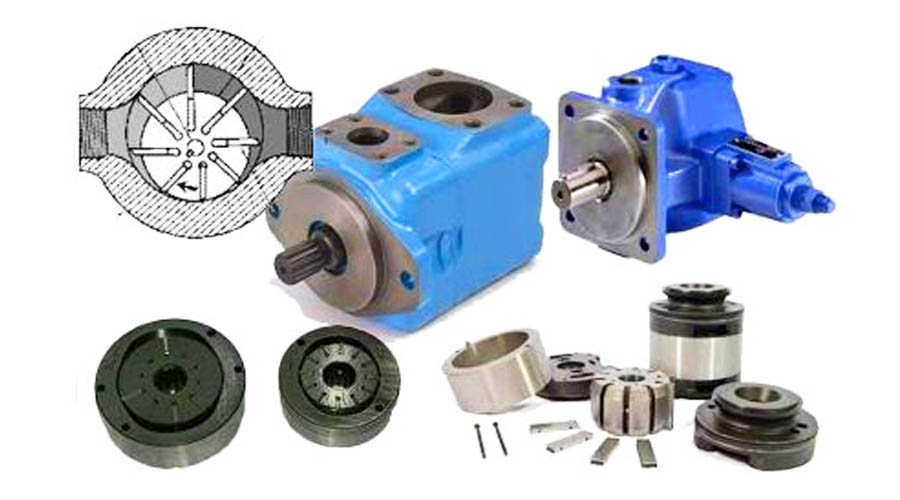

Vane pumps work using a rotor that rotates within a cavity. The rotor is equipped with multiple sliding vanes that are moved outward by centrifugal force and pressed against the pump housing. As the rotor turns, the volume between the vanes changes, allowing the pump to draw in and out fluid.

Design Advantages: The sliding vanes remain in constant contact with the pump housing, resulting in smoother fluid delivery and lower pulsation.

Hydraulic Gear Pumps:

Gear pumps are generally available in two types: external gear pumps and internal gear pumps. External gear pumps use two meshing gears to rotate to create suction and deliver fluid. Internal gear pumps use one gear rotating inside another, using crescent-shaped washers to direct the fluid.

2. Structure and complexity

Standard Vane pump Gear pump

Internal structure More complex (sliding vanes, rotors, cam rings) Simpler (meshing gears only)

Maintenance Requires more precise assembly and regular vane inspection Easier to maintain and assemble

Size and weight Typically larger due to internal mechanical structure Compact and lightweight

Key points: Vane pumps are more complex, but perform better in precision systems. Gear pumps have fewer moving parts, long-term reliability and cost-effectiveness.

3. Hydraulic pressure and flow characteristics

Vanilla pumps:

Maximum pressure: Typically up to 210 bar (3000 psi)

Flow pulsation: Very low, quieter operation

Flow control: Highly controllable, suitable for variable displacement designs

Gear pumps:

Maximum pressure: Approximately 250 bar (3600 psi), depending on model and brand

Flow pulsation: Larger pulsation compared to vane pumps

Flow control: Slower response, mainly used in quantitative systems

Insight: Vane pumps are the first choice for applications that require smooth flow and low noise, such as CNC machine tools, injection molding machines or indoor hydraulic systems. For industrial vehicles or construction equipment, gear pumps are rugged and have higher pressure resistance.Contact Us

4. Hydraulic vane pumps Gear pump efficiency and energy saving

Efficiency is a key indicator for hydraulic systems, especially today when all industries are pursuing better energy management and sustainable development.

Vanilla pump efficiency: Generally has high volumetric efficiency and mechanical efficiency, especially in variable displacement vane pumps.

Gear Pump Efficiency: Good efficiency at high pressures, but may decline at low speeds or long cycles due to internal leakage.

With the rise of energy-efficient hydraulic solutions, vane pumps are increasingly being used in applications that require variable flow without the need for inverters or motor speed control.

5. Cost vs. Application Comparison

Factor Vane Pump Gear Pump

Initial Cost Higher Lower

Long-term Cost Lower due to high efficiency and long maintenance intervals Higher cost under extreme conditions

Typical Applications Plastic machinery, presses, elevators Dump trucks, tractors, industrial lifts

For example, Poocca vane pumps are often selected by customers for injection molding, precision metallurgy, and automated assembly lines.

On the other hand, Poocca gear pumps (including models that are interchangeable with Parker, Rexroth, and Shimadzu) are exported for construction vehicles, dump trucks, and mining machinery for reliability and cost-effectiveness.

6. Noise Level and Vibration

This is an often overlooked factor, but it is important in environments where operator comfort, city regulations, or machine stability are a priority.

Vane pumps run more smoothly, with significantly lower vibration and noise levels (as low as 60 dBA).

Gear pumps generate more noise due to the meshing of the gears, especially at high pressures and speeds.

Recommendation: Use vane pumps in environments where noise is a concern, such as laboratories, hospitals, or indoor plants.

7. Lubrication and fluid compatibility

Hydraulic vane pumps: Require cleaner hydraulic oil to prevent vane wear. Vane pumps are more sensitive to contamination.

Gear pumps: Can handle higher viscosity or more contaminated fluids, suitable for outdoor or heavy-duty operations.

Gear pumps may last longer if you are using poor filtration or higher viscosity fluids.

8. Lifespan and maintenance

While both pumps can last for many years, they have different maintenance cycles:

Vane pumps: May require regular inspection/replacement of vanes. However, modern models (such as the Poocca variable displacement vane pump) feature self-compensating vanes that extend life.

Gear pumps: Easier to maintain, but wear on the gear teeth over time may reduce performance, especially when used with abrasive fluids.

Regardless of pump type, choosing the right filtration and maintenance schedule can extend service life.

Final Comparison Summary

Features Vane Pump Gear Pump

Complexity High Low

Precision & Control Excellent Medium

Noise Level Low Medium-High

Pressure Rating Medium High

Cost Higher initial cost, shorter service life Lower initial cost, longer service life

Fluid Cleanliness Requires cleaner fluids More tolerant of contamination

Typical Industry Uses Machine Tools, Robotics, Elevators Agriculture, Transportation, Construction

Conclusion: Which Should You Choose?

The choice between vane and gear pumps depends largely on your application:

If your system requires low noise, precise control, and energy savings, choose a vane pump.

If you need a rugged, low-cost solution that can handle tough fluids and operate in harsh environments, choose a gear pump.

If you’re unsure, consult a trusted hydraulic manufacturer like Poocca, who offers vane and gear pump solutions with customization support, technical support, and fast global shipping.

9.Why Choose Poocca Hydraulic Manufacturer?

As a leading supplier in the global hydraulic market, Poocca offers:

Full range of vane pumps and gear pumps, compatible with leading brands

OEM and ODM production options

Professional sales engineers to assist with selection and customization

Affordable prices, 12-month warranty

In stock, fast delivery

Contact Poocca now

Let us help you choose the best pump for your project.

Post time: Jun-19-2025