A hydraulic gear pump on a ship is a positive‑displacement hydraulic pump installed in a vessel’s onboard hydraulic system that converts mechanical input from an engine, motor, or power take‑off (PTO) into pressurized hydraulic fluid flow. It does this by using meshing gears enclosed in a close‑fitting casing to draw in fluid and deliver it into the ship’s hydraulic circuits under pressure. This steady, predictable flow makes gear pumps popular in many marine applications where reliability and simplicity are critical.

In maritime contexts, gear pumps are designed and selected with marine‑specific demands in mind — including vibration, humidity, salt‑air corrosion, and constrained equipment spaces — to support key systems such as steering, deck machinery, and auxiliary hydraulics.

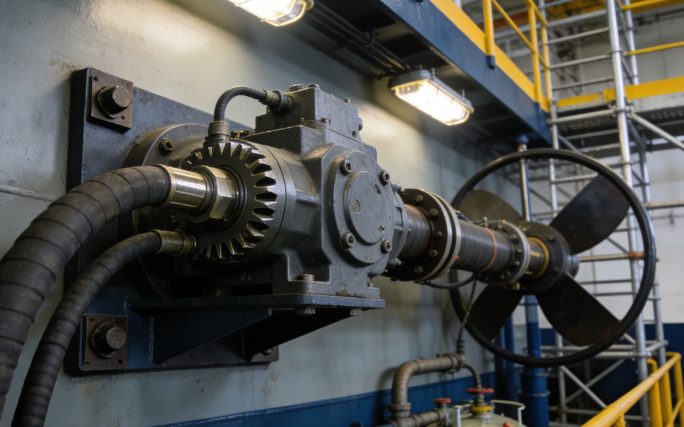

What Is a Gear Pump — Core Technical Overview

In its most basic form, a gear pump is a positive‑displacement rotary pump that moves fluid by trapping a defined volume between the rotating gear teeth and the pump casing, then discharging it as the gears mesh again. Each full rotation delivers a consistent, predictable amount of fluid, which makes gear pumps ideal for steady hydraulic systems on ships.

Common Gear Pump Types Used on Ships

Marine gear pumps are usually categorized by their gear configuration, with the two most common forms being:

1. External Gear Pumps

-

Feature two identical gears meshing side‑by‑side.

-

One gear is driven directly while the other rotates through gear meshing.

-

This simple design makes them widely used in marine hydraulics for general hydraulic power circuits and steering gear systems.

2. Internal Gear Pumps

-

Use a driving gear inside an outer gear; fluid is moved through the expanding and contracting spaces between the gears.

-

These pumps can handle slightly different viscosity ranges and may be used where softer materials or smoother flow is desired.

Although internal gear pumps appear in specific applications, external gear pumps are generally the dominant choice in marine hydraulic systems due to their simplicity, robustness, and ease of service.

Marine Considerations in Design

While the basic operating principle is universal, marine gear pumps are tailored for shipboard environments. Materials, seals, and geometric tolerances are selected to withstand salt air, vibration, varied fluid viscosities, and tight equipment spaces.

The marine environment places particular emphasis on corrosion resistance and wear tolerance, often requiring bronze or stainless housings and enhanced sealing to maintain volumetric efficiency over long service hours.

How Hydraulic Gear Pumps Work on Ships

A hydraulic gear pump on a ship operates on a positive‑displacement rotary principle, meaning it delivers a fixed volume of fluid for each revolution of its internal gears. This consistent mechanical action produces a steady flow of hydraulic oil that can be relied upon in marine systems.

Step‑by‑Step Working Mechanism

Although there are variations in design, the most common marine gear pump is the external gear pump, which works as follows:

-

Drive Input: A prime mover — such as an electric motor, diesel engine PTO, or auxiliary drive — rotates the pump’s driving gear.

-

Fluid Intake: As the gears turn, the teeth on the suction side separate (unmesh), creating an increasing cavity volume and a local reduction in pressure. This low pressure draws hydraulic oil in from the reservoir.

-

Fluid Transport: The fluid becomes entrapped between the gear teeth and the casing. Because of this positive‑displacement action, the fluid is carried around the outer periphery of the gears toward the discharge port.

-

Fluid Discharge: On the discharge side, gear teeth mesh back together (reducing cavity volume), squeezing the fluid out into the system at pressure.

-

Repeat Cycle: With every rotation, the pump moves the same volume of fluid, so flow rate is directly proportional to rotational speed (RPM) — making output predictable and stable.

Why They Are Widely Used on Ships

1. Reliable and Robust in Marine Conditions

Gear pumps have a straightforward mechanical design with fewer moving parts, which means there is less that can go wrong under demanding conditions such as vibration, humidity, and continuous operation. This reliability is especially valuable in steering gear systems and deck machinery, where failure can disrupt critical ship operations.

2. Predictable, Steady Flow

Because gear pumps are positive‑displacement, each gear rotation delivers a fixed volume of fluid. This ensures a consistent and predictable flow rate, which simplifies system design and helps maintain stable performance for hydraulic actuators like cylinders and motors.

3. Compact and Space‑Efficient

Marine engine rooms and auxiliary machinery spaces are often tight. Gear pumps are generally smaller and lighter than many alternatives, requiring less installation space while still providing reliable power.

4. Cost‑Effective Solution

Compared with more complex pumps (like large piston pumps), gear pumps typically have lower upfront costs and simpler maintenance needs because of their basic construction. This contributes to a lower total cost of ownership for ship operators.

5. Good Suction and High Viscosity Handling

Gear pumps handle a wide range of fluid viscosities — including the thicker hydraulic oils often used on ships — and can be designed to maintain good suction performance in these conditions.

Typical Marine Hydraulic Applications

Hydraulic gear pumps are versatile and widely used on ships because they deliver steady, reliable hydraulic power for a variety of essential marine systems. In most vessels — from cargo ships and tankers to offshore support and fishing boats — gear pumps serve as the energy source for actuating equipment that must operate dependably under harsh sea conditions.

Key Shipboard Uses

Here are the most common marine applications where hydraulic gear pumps are typically found:

1. Steering Gear Systems – Hydraulic steering systems use pumps to supply pressurized oil to steering cylinders or actuators that move the rudder. Gear pumps are often chosen here for simple, predictable performance and good response under load.

2. Winches and Capstans – Winches for mooring, anchoring, towing, and line handling rely on hydraulic power to provide torque and control. Gear pumps deliver consistent flow needed for controlled pull and payoff.

3. Deck Machinery (Cranes, Davits, Hatch Covers) – Deck cranes, davits, hatch covers, and other lifting or loading devices frequently use hydraulic circuits driven by gear pumps. This allows for precise motion control and load handling.

4. Anchor and Mooring Systems – Hydraulic systems operating windlasses and anchor chain equipment depend on hydraulic pumps to rotate drums and motors safely.

5. Auxiliary and Secondary Circuits – Smaller gear pumps are also used in secondary circuits such as lubrication, steering power packs, hydraulic tools, and control manifolds. Because gear pumps are compact and cost‑effective, they are well suited for auxiliary duties.

Key Selection & Specification Guide

Selecting the right hydraulic gear pump for a ship means matching pump capabilities with your system’s operational demands. Start by defining the required flow rate and pressure: calculate the maximum flow needed (based on actuators like steering or deck machinery) and ensure the pump’s rated pressure comfortably exceeds system peaks plus a safety margin. This prevents premature wear and ensures stable performance.

Next, confirm drive compatibility. The pump’s speed (RPM) must align with the chosen motor or power take‑off. Operating outside the recommended range can lead to cavitation or inefficiency. Also consider hydraulic fluid properties — viscosity and temperature range influence internal leakage and suction performance. The pump must be designed to handle your specific fluid.

For marine environments, material and corrosion resistance are critical. Choose materials (e.g., cast iron, stainless steel) and seal types that withstand salt air and vibration. Finally, check installation conditions like suction line layout and inlet lift to avoid cavitation, and ensure proper coupling, vibration isolation, and support for easy service and long life.

Common Misconceptions Explained

Even experienced engineers sometimes make incorrect assumptions about hydraulic gear pumps. Clearing up these myths helps make better decisions when specifying or troubleshooting marine systems.

Myth 1: Gear pumps can reliably handle any fluid.

Reality: Gear pumps rely on tight internal clearances. Very low‑viscosity fluids can slip back internally, reducing output and efficiency. Similarly, very high viscosity can cause increased torque, cavitation, or startup difficulty.

Myth 2: Once installed, they run without maintenance.

Reality: While simpler than some pump types, gear pumps still need fluid cleanliness, periodic inspection, and correct lubrication. Neglecting this accelerates wear and reduces volumetric efficiency.

Myth 3: Gear pumps can run dry safely.

Reality: Gear pumps depend on pumped fluid for lubrication. Running dry can cause overheating, wear, or irreversible damage.

Myth 4: Gear pumps can internally adjust flow or pressure.

Reality: Most marine gear pumps are fixed‑displacement. Pressure and flow adjustments require external controls, such as speed variation or relief valves.

Conclusion

A hydraulic gear pump on a ship is a fundamental component of marine hydraulic systems, converting mechanical motion into steady hydraulic flow by using meshing gears — typically in external gear configurations. These pumps are valued for simplicity, predictable flow, compact size, and robustness in harsh shipboard environments.

In ship applications, they are widely used for steering gear, winches, deck machinery, and auxiliary circuits. Understanding their operating principles, advantages, and limitations — and selecting the right pump based on flow, pressure, fluid properties, and marine conditions — ensures reliable performance and longevity at sea.

Clearing up common misconceptions about fluid compatibility, maintenance, dry running, and pump control helps you avoid performance issues and extend service life.

If you need professional guidance on choosing or sizing a marine hydraulic gear pump, or want a custom solution for your ship’s hydraulic system, contact our team at Poocca — we’re ready to help you build a robust, efficient hydraulic power system.

Post time: Feb-03-2026