In the ever-evolving world of hydraulic systems, control valves play a pivotal role in regulating fluid flow and pressure. These essential components are vital for ensuring efficient and precise control over machinery and processes in various industries. This article explores the significance of control valves in the hydraulic industry, their functions, advancements, and their impact on improving productivity and safety.

The Basics of Control Valves:

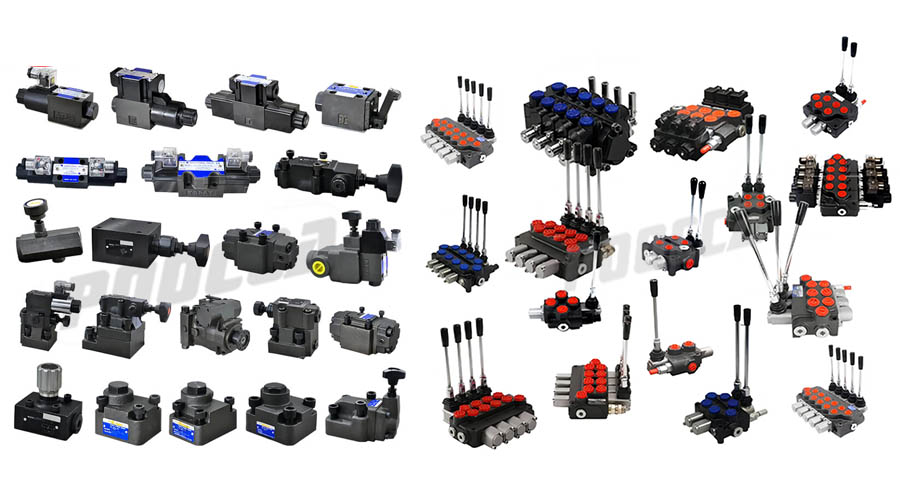

Control valves are devices that manage the flow and direction of fluids within a hydraulic system. They enable the operator to regulate the speed, direction, and force of hydraulic actuators. Control valves consist of various components, including a valve body, spool, actuator, and control mechanism. These valves are available in different types, such as pressure control valves, flow control valves, directional control valves, and proportional control valves.

Functions and Applications:

Control valves serve a multitude of purposes in hydraulic systems. They control the pressure and flow of hydraulic fluid, ensuring smooth operation of equipment. These valves find applications in industries like manufacturing, construction, agriculture, and transportation. From heavy machinery and construction equipment to precision tools and automation systems, control valves are integral to enhancing performance and efficiency.

Advancements in Control Valve Technology:

With rapid technological advancements, control valves have also undergone significant improvements. Modern control valves now feature advanced sensors, actuators, and electronic controls that enhance precision and responsiveness. Proportional control valves, for instance, allow for precise control of fluid flow rates, resulting in more accurate and efficient operations. Additionally, the integration of smart technologies like IoT (Internet of Things) enables remote monitoring and control of hydraulic systems, leading to improved maintenance and troubleshooting.

The Impact of Control Valves on Productivity:

The proper selection and utilization of control valves can have a substantial impact on productivity in various industries. By maintaining optimal fluid flow and pressure, control valves minimize energy losses, reduce downtime, and enhance overall system efficiency. With better control over equipment, operators can achieve higher production rates and improved product quality. The reliability and performance of control valves contribute significantly to the success of hydraulic systems and their overall productivity.

Safety Considerations and Control Valve Regulations:

Safety is a crucial aspect of hydraulic systems, and control valves play a critical role in ensuring safe operation. Control valves help maintain stable hydraulic pressure, preventing equipment damage and potential hazards. Adhering to industry standards and regulations is vital for control valve manufacturers and system integrators to ensure the safety of workers and equipment. Compliance with safety standards like ISO 13849 and functional safety requirements is essential for the proper design, installation, and operation of control valves.

Future Trends and Outlook:

The future of control valves in the hydraulic industry looks promising. Advancements in materials, design, and control technologies will continue to enhance their performance and reliability. The integration of artificial intelligence and machine learning algorithms may enable control valves to adapt dynamically to changing operating conditions, optimizing system performance and energy efficiency. Furthermore, the increasing focus on sustainability and environmental impact may drive the development of eco-friendly control valve solutions in the years to come.

Conclusion:

Control valves are the backbone of hydraulic systems, providing precise control over fluid flow and pressure. As technology advances, these valves continue to evolve, offering enhanced performance, safety, and efficiency. The hydraulic industry relies on control valves to optimize productivity and achieve superior results in various applications. With ongoing innovations and a growing emphasis on sustainability, control valves are poised to play an increasingly vital role in shaping the future of the hydraulic industry.

POOCCA hydraulic manufacturer’s main products include: gear pumps, plunger pumps, vane pumps, motors, hydraulic valves, accessories, among which hydraulic valves include Rexroth 4we hydraulic valve, DBDH, p40, p80, p120, Yuken DFB, DFA, ZDB, with favorable prices, fast delivery from stock, and a 12 month shelf life.

Post time: Jul-05-2023