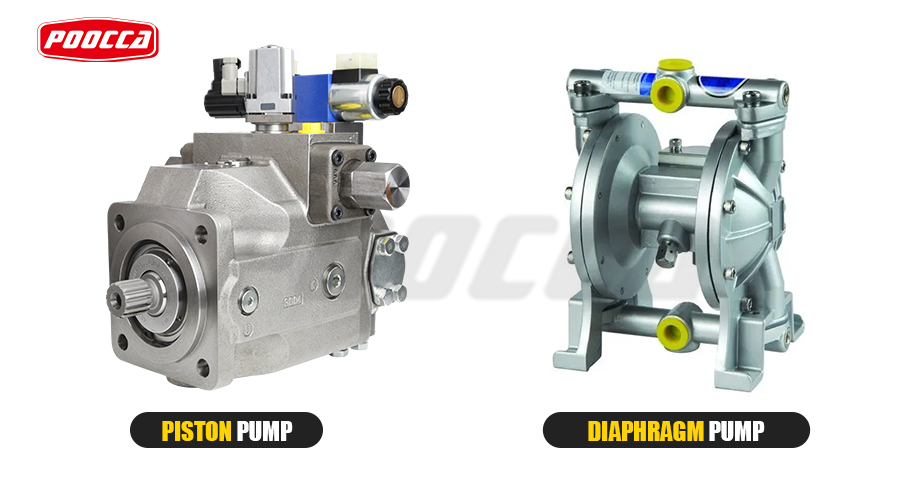

The choice between a piston pump and a diaphragm pump depends on the specific application and its requirements. Each type of pump has its advantages and disadvantages.

Piston Pump:

Advantages:

High efficiency: Piston pumps are known for their efficiency and can generate high pressure.

Precise control: They offer excellent control over flow rates and pressure.

Suitable for a wide range of viscosities: Piston pumps can handle both low and high-viscosity fluids.

Limited for clean fluids: Piston pumps can be sensitive to particulate matter and abrasive materials.

Maintenance: They may require more maintenance due to the potential for wear and tear on seals and pistons.

Diaphragm Pump:

Advantages:

Versatility: Diaphragm pumps can handle a variety of fluids, including corrosive and abrasive ones.

Low maintenance: They have fewer moving parts, which often leads to reduced maintenance requirements.

Suitable for slurries: Diaphragm pumps are effective in handling fluids with suspended solids.

Disadvantages:

Lower efficiency: Diaphragm pumps are generally less efficient than piston pumps, especially at high pressures.

Limited for high-pressure applications: They may not be suitable for applications that require very high pressure.

In summary, the choice between a piston pump and a diaphragm pump depends on the specific needs of the application. If precision, high pressure, and clean fluids are essential, a piston pump may be the better choice. On the other hand, if versatility, resistance to abrasive or corrosive materials, and low maintenance are more critical, a diaphragm pump may be the preferred option.

There are many models of poocca piston pumps. Send your needs and questions immediately, and we will reply to you as soon as possible and provide you with quotations and preferential discounts.

For sale 100% alternative brands: Rexroth, Parker, Vickers, Yuken…

Post time: Oct-24-2023