A “double gear pump”—also called a tandem gear pump—is a variation of the standard gear pump designed to supply two separate fluid outputs from a single drive unit. This makes it especially valuable in hydraulic systems requiring multiple circuits, independent flow rates, or different pressure demands. The goal here is not just to define the term, but to help you understand real-world value, recognize correct use cases, avoid common pitfalls, and make confident purchasing decisions.

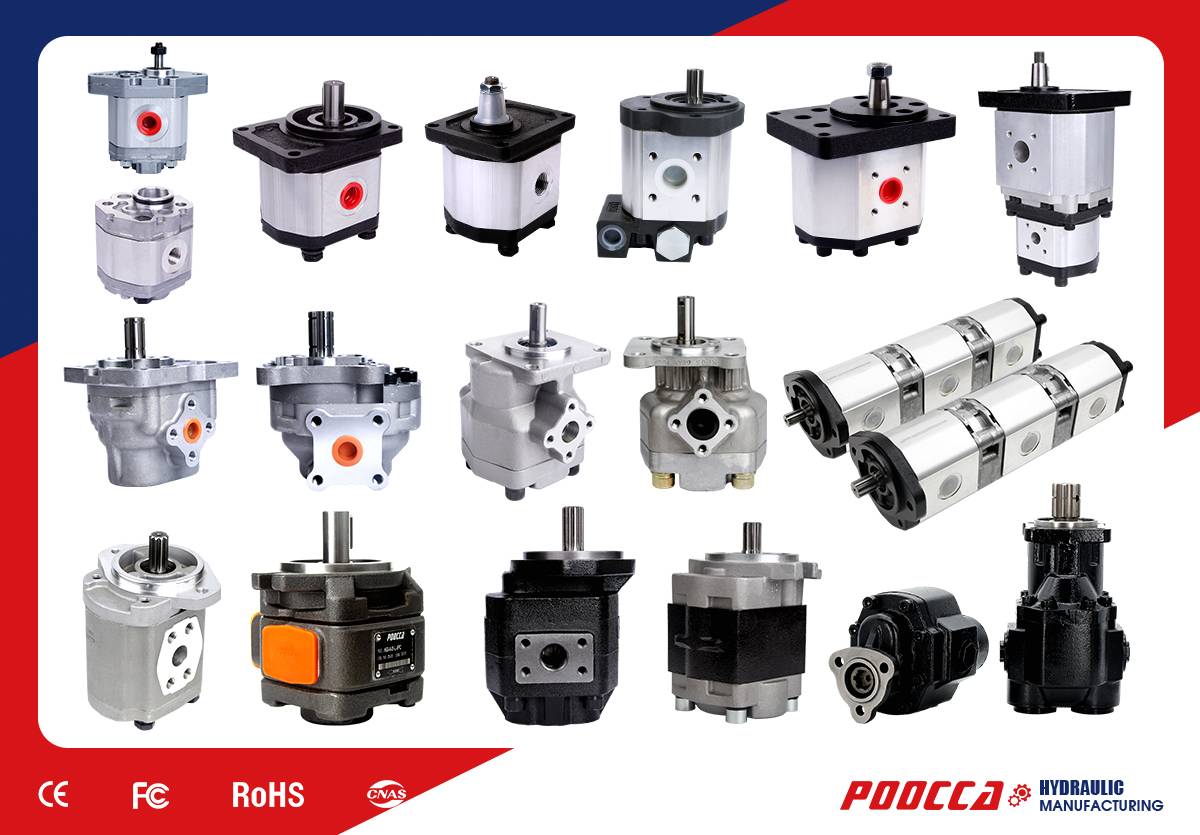

Twin gear pump concept

A double gear pump—also commonly called a tandem gear pump or dual gear pump—is a specialized type of hydraulic positive-displacement gear pump in which two individual gear-pump sections are integrated into a single housing and driven by one common input shaft. Each section contains its own gear set and typically its own discharge port, allowing the pump to supply two separate fluid flows or hydraulic circuits simultaneously.

How It Differs from a Single Gear Pump

To understand the essence of a double gear pump, it helps to contrast it with a single gear pump:

-

A single gear pump has one pair of meshing gears, one inlet, and one outlet, delivering a single flow circuit.

-

A double gear pump, by contrast, combines two gear pump modules inside one housing, with each module independently moving fluid while sharing the same drive source.

This design means you can power two distinct hydraulic lines or functions from the same mechanical input without needing two separate pump bodies—saving space, simplifying installation, and often lowering overall system cost.

Key Structural Elements

A typical double gear pump includes:

-

Common drive shaft: One shaft that transmits power to both gear sections.

-

Two gear sets: Each with its own gears, bearings, and chamber, sized for the desired displacement.

-

Intermediate partition: A structural wall separating the two sections to prevent internal interference.

-

Inlet and outlet ports: Often a shared suction port for both sections and two separate discharge ports; some designs may use dual inlets for complete circuit independence.

How a Double Gear Pump Works — Step-by-Step

Step-by-Step Operation

1. Drive Shaft Rotation

The pump’s input shaft—typically powered by a hydraulic motor or engine—rotates. Because both gear sets are mounted on this common shaft, they begin turning in unison as soon as the shaft spins.

2. Fluid Intake (Suction)

As each gear set rotates, the teeth on each section unmesh slightly at their inlet sides, creating small voids or low-pressure zones. These expanding spaces cause fluid to be drawn into each section from the reservoir. Many designs share one common suction port for both sections to simplify plumbing, although some configurations provide separate suction paths when full independence of circuits is required.

3. Trapping and Transport

Once fluid enters the pump, the rotating gear teeth trap it between the tooth flanks and the casing wall. The gears then carry this trapped fluid along the outer periphery of their respective pump sections, maintaining separation between the high-pressure and low-pressure sides.

4. Compression and Discharge

As the gears approach the discharge side, the spaces between teeth get progressively smaller. This reduction in cavity volume compresses and forces the fluid out of each section’s outlet port under pressure. Because both sections operate simultaneously, you get two streams of fluid—each with predictable volume per revolution.

5. Continuous Operation

This cycle—suction, transport, and discharge—repeats continuously with every revolution of the shaft. Since the pump moves a fixed volume per section per revolution, the flow from each output is proportional to rotational speed and the displacement size of that section.

Technical Features & Internal Design

A double (tandem) gear pump integrates two gear pump sections in a single housing with a common drive shaft, allowing it to deliver two independent fluid paths from one power source. This compact integration is a core structural advantage.

Core Structural Traits

-

Common Drive Shaft: One input shaft drives both gear sets, simplifying the drive system.

-

Dual Gear Sets: Each section has its own gears and chamber, providing separate outputs that can be used independently or combined downstream.

-

Intermediate Partition: A wall or seal prevents unwanted leakage between the two sections.

-

Inlet/Outlet Options: Often a shared suction port with two independent discharge ports, though dual inlets are possible for fully independent circuits.

Performance Considerations

-

Displacement Flexibility: Sections can be sized differently (e.g., one high-flow, one low-flow) to match system requirements.

-

Pressure & Speed: Typical industrial tandem gear pumps handle pressures up to ~250 bar and speeds suited to fixed-displacement gear pumps’ normal operating ranges.

-

Materials & Manufacturing: Precision gears, bearings, and tight clearances help ensure long life and maintain volumetric efficiency.

Advantages of Double Gear Pumps

• Compact, Space-Saving Design

Because two pumping sections are integrated into one housing with a shared drive shaft, a double gear pump takes up less installation space than two separate single pumps. This compactness simplifies system layout and reduces the amount of structural support needed.

• Dual-Output Flexibility

One of the biggest benefits is the ability to provide two independent flows or circuits. Each pump section can feed a different hydraulic path—such as one for high-flow/low-pressure and another for low-flow/high-pressure—without the need for extra pumps. This enables design flexibility in complex machines.

• Simplified Drive & Plumbing

With a single input shaft and often a common suction port, double gear pumps reduce the number of couplings, hoses, and fittings required. Fewer components mean lower installation complexity and fewer potential leak points in the hydraulic system.

• Predictable, Stable Flow

As a positive-displacement design, gear pumps deliver flow that is largely proportional to shaft speed multiplied by displacement. This predictability makes it easier to size and control hydraulic systems, especially ones with strict performance requirements.

Limitations & Design Challenges

While double gear pumps bring valuable benefits, they also have real practical limitations you need to consider before choosing one. Understanding these helps avoid performance issues, costly mistakes, and maintenance headaches in your hydraulic system design.

• Internal Leakage (“Slip”) and Efficiency Drop

Because gear pumps rely on tight clearances between gear teeth and housing, some fluid inevitably leaks back across those clearances. Under high pressure or as the pump wears, this leakage (“slip”) increases, which reduces actual flow and overall volumetric efficiency.

• Precision Manufacturing Is Essential

A double gear pump has two sections in one casing. To maintain performance, gear alignments, clearances, and internal sealing must be very precise. If tolerances aren’t tight or if machining quality is poor, performance drops and wear accelerates.

• More Complex Maintenance

If one section of a double gear pump fails or wears out, you usually must disassemble the entire unit to service it. This makes maintenance more complex and potentially more expensive than servicing a single gear pump.

• Sensitive to Suction and Cavitation

Double gear pumps are sensitive to inlet conditions. Restricted or unstable suction flow can cause cavitation (formation and collapse of vapor bubbles), which damages internal components and reduces life.

• Not Ideal for Abrasive or Particulate Fluids

Like most gear pumps, double gear pumps aren’t suitable for fluids with large solid particles. Abrasives accelerate wear of gears, bearings, and seals, shortening service life and reducing reliability.

• Noise and Wear Over Time

The meshing of gear teeth and internal turbulence can generate noise and vibration, especially at high speed and pressure. With time, increased wear also contributes to noise and lower performance.

Where Double Gear Pumps Are Used — Application Scenarios

1. Construction & Earthmoving Machinery

Machines such as excavators, loaders, bulldozers, and backhoes often need more than one hydraulic circuit working at the same time—for example, boom lift, bucket tilt, or steering functions. A double gear pump can supply different flows to these functions from one compact unit, reducing space and complexity compared with installing two separate pumps.

2. Compact Hydraulic Power Units (HPUs)

In mobile power packs, skid-mounted HPUs, or integrated hydraulic modules, space is often limited. Double gear pumps help designers achieve multiple flow outputs within a tight footprint, simplifying plumbing and lowering the number of components needed.

3. Dual-Circuit Systems

Some systems require two different flow/pressure outputs simultaneously—for example:

-

A high-flow, low-pressure circuit for rapid motion, and

-

A low-flow, high-pressure circuit for heavy lifting forces.

A double gear pump can deliver these distinct outputs from one shaft and housing, improving system efficiency and reducing installation cost.

4. Agricultural Machinery

Tractors, harvesters, sprayers, and other farm equipment often need to power steering, lift, and auxiliary implements at the same time. A tandem gear pump can serve these multiple functions with fewer external components and a smaller overall hydraulic footprint.

5. Material Handling & Mobile Equipment

Equipment like forklifts, telehandlers, cranes, and transporters frequently has multiple simultaneous hydraulic needs—lifting, tilting, and auxiliary accessories. The dual outputs of a double gear pump make it suitable for compact and responsive systems.

6. Industrial Automation & Presses

In manufacturing and automation systems that require parallel hydraulic functions—such as one slow, high-force path and one fast, low-force path—a double gear pump can simplify system design while maintaining predictable flow behavior.

How to Choose the Right Double Gear Pump

-

Define flow and pressure requirements so the pump’s displacement and pressure ratings match your system’s peak and continuous demands.

-

Verify fluid properties (viscosity, temperature, chemistry) to ensure compatibility with pump materials and seals.

-

Assess suction conditions and installation constraints (inlet design, lift, piping) to avoid cavitation and installation issues.

-

Check mounting, shaft size, and interface standards to ensure seamless integration into your system.

-

Use performance curves and safety margins to finalize the correct model for reliable long‑term operation.

Common Misconceptions

Even experienced engineers and buyers sometimes believe incorrect things about gear pumps and double gear pumps. These misunderstandings can lead to poor system design or selecting the wrong pump for the application. Here are key misconceptions clarified:

1. “Double gear pumps inherently increase pressure.”

Reality: A double gear pump does not inherently double or increase pressure beyond its design rating—each section produces pressure up to the pump’s specified limit. Pressure capacity depends on the pump’s materials, tolerances, and design, not simply having two sections.

2. “Gear pumps are the only way to make pressure differentials.”

Reality: Other positive‑displacement pumps—such as vane pumps or piston pumps—can also create significant pressure differentials. Gear pumps’ strength is steady flow and reliability, not exclusivity in generating pressure.

3. “Fixed‑displacement means no flow or pressure control.”

Reality: While gear pumps deliver a fixed volume per revolution, you can adjust flow using variable speed drives or external control valves. This doesn’t change the displacement but modulates effective system flow.

4. “Flow rates listed on datasheets are exact in all conditions.”

Reality: Nominal flow is a theoretical value. Real output varies due to internal leakage (“slip”), fluid viscosity, pressure, and wear over time—actual flow is usually lower than the ideal number.

5. “Gear pumps can reliably handle any fluid.”

Reality: Because gear pumps depend on tight internal clearances, they perform best with clean, compatible hydraulic fluids. Abrasive particles or inappropriate media accelerate wear and shorten life.

Summary & Call to Action

A double (tandem) gear pump is a positive‑displacement hydraulic pump that integrates two gear pump sections in one housing, driven by a single input shaft to supply two independent fluid outputs. It delivers predictable flow proportional to shaft speed and displacement, making it invaluable in systems with multiple hydraulic circuits or varying flow needs.

Why double gear pumps are widely used:

-

Space‑saving, compact integration compared with two separate pumps.

-

Dual‑output flexibility—each section can serve its own circuit, even with different flows.

-

Simplified drive and plumbing.

-

Stable positive‑displacement flow, valuable for predictable hydraulic performance.

Who benefits most: construction and earthmoving equipment, compact hydraulic power units, agriculture and material handling machinery, and any system that requires separate circuits from one pump.

If you’re evaluating options for your next hydraulic project or OEM design, choosing the right pump matters: getting the correct flow profiles, pressure capabilities, suction design, and interface standards ensures your system runs efficiently and reliably. Issues like internal leakage, component wear, and cavitation only become critical if the pump is mismatched to the application.

Next step: For custom sizing, displacement combinations, installation advice, or a competitive quote on a double gear pump tailored to your system, contact Poocca Hydraulic. Our engineering team can help you select the best solution based on your actual flow, pressure, and space constraints — not guesswork.

Post time: Jan-14-2026