In hydraulic systems, vane pumps are prized for smooth flow, self-priming capability, and reliable performance in many industrial and mobile applications. Yet even these well-engineered machines can fail prematurely — leading to downtime, high repair costs, and reduced system efficiency. Understanding the true root causes of vane pump failure is key to reducing total lifecycle costs, improving reliability, and choosing the right pump for your needs. This article breaks down the most common failure mechanisms, what triggers them, and why they matter from both a technical and business perspective.

How Vane Pumps Work — Technical Overview

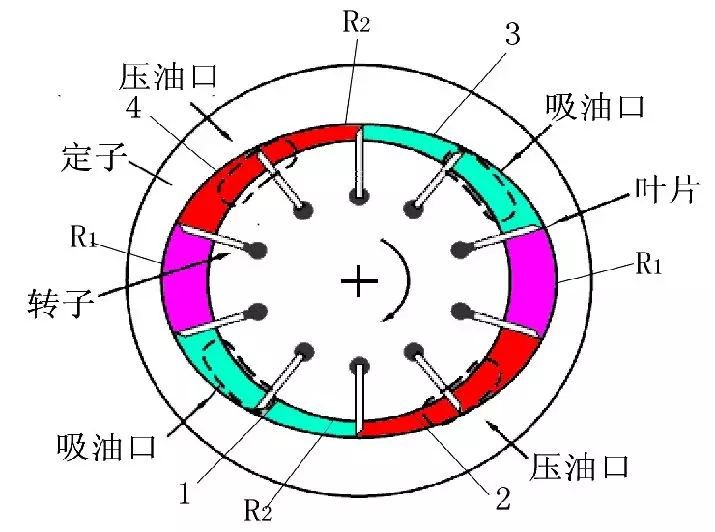

Hydraulic vane pumps convert mechanical energy into hydraulic energy by using a rotor and sliding vanes inside an eccentric cam ring. As the rotor turns, the vanes extend outward under centrifugal and hydraulic forces, trapping fluid and moving it from the inlet side to the outlet side. This design enables smooth, continuous flow and good performance in medium-pressure systems. However, tight tolerances and dynamic internal motion also make vane pumps sensitive to operating conditions and fluid quality.

The core moving parts — vanes, rotor, cam ring and housing — must maintain precise clearance for efficient sealing and flow. Any disruption to this balance — whether from contamination, improper fluid properties, mechanical stress, or suction disturbances — can lead to performance loss and eventual failure. Because vane pumps are often at the front line of a hydraulic circuit, their failure can quickly ripple through the entire system, reducing productivity and increasing maintenance costs.

Primary Failure Causes of Vane Pumps

Fluid Contamination — The Top Killer

Contaminated hydraulic fluid is widely recognized as the leading cause of vane pump failure. Particles such as dirt, metal flakes, or debris scratch and abrade the vanes, rotor, and housing, increasing clearances and internal leakage. Water or chemical contaminants can corrode parts and degrade lubrication, accelerating wear and reducing service life. According to industry sources, over 80% of vane pump failures are associated with fluid contamination.

Why it matters:

-

Increases friction and heat.

-

Reduces sealing effectiveness between moving parts.

-

Leads to performance loss (reduced flow/pressure).

Cavitation & Aeration — Suction-Side Damage

Cavitation and aeration are common “silent killers” of vane pumps.

-

Cavitation occurs when the pressure at the pump inlet drops below the fluid’s vapor pressure, forming vapor bubbles that implode as they move into high-pressure zones. This violent collapse causes pitting and erosion on vane tips and internal surfaces.

-

Aeration happens when air enters the fluid — through leaks, low fluid levels, or turbulence — and reduces lubrication film, leading to rough running and increased internal wear.

Why it matters:

Cavitation not only damages the vane and cam surfaces but can also lead to severe mechanical stresses and sudden failure if left unchecked.

Incorrect Fluid Viscosity & Lubrication Problems

Using the wrong hydraulic fluid or operating outside recommended viscosity ranges compromises lubrication.

-

Too high viscosity increases friction, making vanes struggle to slide and causing heat buildup.

-

Too low viscosity reduces film strength, leading to metal-to-metal contact and accelerated wear.

Why it matters:

This affects both efficiency and longevity — pumps with incorrect fluid conditions tend to run hotter and wear faster.

Installation & Mechanical Issues

Mechanical problems originating from installation errors are a frequent root cause:

-

Shaft misalignment between the pump and driver introduces uneven loads.

-

Incorrect coupling or loose mounting causes vibration and additional stresses.

-

Excessive radial or axial loads accelerate bearing and vane wear.

These issues disrupt the precise clearances vane pumps rely on and can lead to uneven wear or structural faults over time.

Operating Beyond Design Limits

When a vane pump is subjected to pressures, speeds, or loads beyond what it was designed for, it experiences mechanical fatigue and stress:

-

Pressure spikes or shock loads from rapid valve movements

-

Continual operation at or above maximum rated pressure

-

Reverse flow or transient events

These conditions strain internal parts (vanes, cam ring, bearings) faster than normal wear would.

Normal Wear & Fatigue

Even under optimal conditions, vane pumps eventually wear out due to the constant sliding motion of the vanes and pressure cycling. Gradual degradation increases internal clearances, leading to reduced volumetric efficiency and eventual failure unless components are replaced or serviced proactively.

Early Warning Signs of Vane Pump Failure

Detecting signs of vane pump failure early can save significant time and money, prevent catastrophic damage, and maintain hydraulic system performance. Technicians and maintenance teams should pay attention to changes in pump behavior and system indicators that often precede full failure.

Unusual Noises and Vibration

Vane pumps normally run smoothly and quietly. Abnormal sounds such as whining, squealing, knocking or grinding typically indicate internal problems like wearing vanes, cavitation or misalignment. Vibration may also point to mechanical stress or imbalance within the pump.

Decline in Flow or Pressure

A consistent drop in flow rate or system pressure is a classic sign of internal leakage or worn components (vanes, rotor, cam ring). This symptom often precedes visible damage and may signal reduced volumetric efficiency long before total pump failure.

Overheating

Elevated operating temperatures indicate friction build-up due to poor lubrication, incorrect oil viscosity, contamination, or excessive load. Overheating not only reduces efficiency but also accelerates component wear and fluid degradation.

Visible Wear or Leaks

On inspection — whether during scheduled maintenance or when the system is taken offline — look for scoring, grooves, pitting, cracked vanes, or external oil leaks. These physical signs confirm internal damage and usually require corrective action.

Bearing or Alignment Issues

Excessive bearing heat, shaft play, or eccentric motion during operation strongly suggests misalignment or mounting issues, which can reduce vane life and lead to complete pump failure if unaddressed.

Buying & Specification Considerations — Professional Guidance

Match Flow & Pressure to Your Application

Start by defining your system’s required flow rate (L/min or GPM) and maximum operating pressure (bar or PSI).

-

Ensure the pump’s pressure rating safely exceeds your peak system pressure by at least 10–15% to reduce mechanical stress and improve reliability.

-

Avoid simply oversizing the pump for “more performance”: excessive flow can waste energy and increase heat buildup without operational benefit.

Choose the Right Displacement and Type

Vane pumps come in fixed and variable displacement designs:

-

Fixed-displacement pumps deliver a consistent flow and are ideal for stable load systems with predictable requirements.

-

Variable-displacement pumps adjust output according to load, improving energy efficiency in systems with fluctuating demands.

Selecting the type based on your duty cycle reduces wasted energy and heat generation.

Consider Fluid Compatibility & Viscosity

A correct match between pump materials, seals, and your hydraulic fluid type is essential:

-

Confirm that seal materials and internal coatings are compatible with your mineral oil, synthetic, biodegradable, or specialty fluid.

-

Maintaining fluid viscosity within the pump’s recommended operating range ensures proper lubrication and avoids premature wear. Pumps generally perform best within a moderate viscosity range; outside this range internal leakage rises and vane motion becomes difficult.

Drive Speed & Mounting Requirements

-

Check the pump’s allowable input speed range (RPM) and ensure it aligns with your motor or engine speed.

-

Confirm mounting style (flange, foot mount, SAE ports) and shaft configuration to ensure seamless integration without costly adapters.

Filtration and Fluid Quality Planning

Vane pumps are sensitive to contamination and require fine filtration (often 10–25 microns) and regular fluid condition monitoring. Choosing a pump specification without planning filtration and maintenance can undermine pump life and accelerate failure.

Evaluate Efficiency and Acoustic Requirements

-

Consider published efficiency curves — pumps that maintain high volumetric and mechanical efficiency at your operating point reduce energy consumption and heat.

-

Noise level (dBA) can also be a factor in enclosed or personnel-intensive environments; balanced designs typically run quieter.

Conclusion

Vane pump failures are usually not random — they stem from known causes like contamination, cavitation, incorrect fluid conditions, and mechanical stresses. By understanding these mechanisms and choosing the right pump with proper specifications and system planning, you significantly increase pump life, reliability, and system performance. When maintenance teams and engineers appreciate the technical and economic reasons behind vane pump behavior, they can make more informed decisions that reduce downtime and operating costs.

If you’re facing performance challenges or need help selecting a reliable vane pump tailored to your system, contact Poocca’s hydraulic experts for professional consultation, custom recommendations, and support throughout your project.

Poocca Hydraulic is a trusted global hydraulic solutions provider with over 20 years of industry experience in research, design, manufacturing, maintenance, and sales of hydraulic pumps, motors, valves, and accessories. We offer a comprehensive product range including vane pumps, gear pumps, piston pumps, and complete hydraulic systems to meet the needs of construction, industrial, agricultural, and mobile applications. With strict quality control, advanced testing procedures, and adherence to international standards such as ISO, CE, and RoHS, Poocca commits to delivering high‑performance, reliable, and cost‑effective hydraulic solutions for customers worldwide. Whether you need standard models or customized OEM/ODM designs, our expert team is ready to support you in optimizing your hydraulic system performance and reducing operating costs.

Post time: Feb-06-2026