In the field of modern industrial and mobile equipment, production efficiency and equipment performance have become increasingly important. As the basis of mechanical power transmission, the normal operation of the hydraulic system is largely dependent on stable operation of the hydraulic pump. The hydraulic pump is also known as the “heart” of hydraulic system, delivering hydraulic oil to the actuators and motor, thereby providing various types of motion control and power output.

There are numerous hydraulic pumps, one of which the variable displacement hydraulic piston pump is currently the favourite of many engineers and customers. Why would individuals then employ this pump?

This article will give you a simple and clear introduction:

What is a variable displacement hydraulic piston pump?

What are its advantages?

What is the difference from ordinary fixed displacement pumps?

Why do well-known brands like Poocca Hydraulic Manufacturer recommend using this type of product?

Whether you are a novice in the hydraulic industry or a purchaser who is new to hydraulic equipment, this article will help you better understand the value of variable hydraulic piston pumps.

**What is a variable hydraulic piston pump?

A hydraulic piston pump is a positive displacement pump that uses a piston to deliver hydraulic oil under pressure. In a variable displacement pump, the pump’s output flow and pressure can be adjusted by changing the swash plate angle or piston stroke length. This contrasts with a fixed displacement pump, which delivers a constant flow regardless of system demand.

The variable output capability gives these pumps flexibility and efficiency, making them a top choice for dynamic load conditions in mobile equipment, industrial automation, construction machinery, and aerospace applications.

**Key Benefits of Variable Hydraulic Piston Pumps

Let’s take a closer look at the specific benefits that make these pumps a great choice in a wide range of systems.

1. Energy and Power Savings

Variable displacement pumps deliver only the amount of fluid required by the system. This prevents excessive energy consumption, especially under partial load conditions.

Real-world example: In a hydraulic press, the pump automatically reduces displacement when the required pressure is lower, saving up to 30% in energy costs compared to fixed displacement pumps.

This also reduces the need for throttling valves or bypass circuits, further reducing power losses.

2. Reduced Heat, Longer System Life

By operating only when needed and avoiding continuous high pressure operation, these pumps generate significantly less heat. Less heat means:

Reduced cooling requirements.

Reduce thermal stress on seals, hoses and oil.

Extend the life of all hydraulic components.

3. Precise control of complex systems

Variable displacement pumps can be equipped with electronic or hydraulic controllers that adjust displacement based on load sensing or pressure feedback signals. This allows:

Proportional flow control.

Precise pressure regulation.

Smooth and sensitive actuation.

This precision has an impact on injection molding machines, CNC systems and mobile cranes, which must move quickly and in a controlled manner.

4. Compact design saves space

In systems that require multiple flow or pressure zones, variable displacement pumps eliminate the need for multiple fixed pumps or complex flow dividers.

The result: simpler hydraulic circuit design.

Less piping, fewer valves and smaller tank requirements.

5. Lower operating and maintenance costs

Although variable displacement piston pumps have a higher upfront cost, their total cost of ownership is lower due to the following reasons:

Energy savings.

Fewer overheating issues.

Shorter maintenance intervals.

Reduced oil degradation.

According to internal testing by Poocca Hydraulics, customers who switch from gear pumps to variable displacement piston pumps can reduce annual maintenance costs by up to 40%.

6. Load Sensing and Demand Driven Operation

These pumps adapt in real time to varying system needs. They increase displacement under high loads and reduce displacement during idle or light-load operation.

This demand-driven operation extends the life of the hydraulic fluid as well as valves, cylinders and motors.

Fixed Displacement Pumps vs. Variable Displacement Pumps: A Quick Comparison

Features Fixed Displacement Pumps Variable Displacement Pumps

Flow Output Constant Adjustable

Energy Efficiency Low High

System Control Limited Precise

Heat Generation High Low

Initial Cost Lower Higher

Maintenance Interval More Frequent Less Frequent

Applications Simple Systems Complex, Load Sensing Systems

**Why Choose Poocca Variable Displacement Piston Pumps?

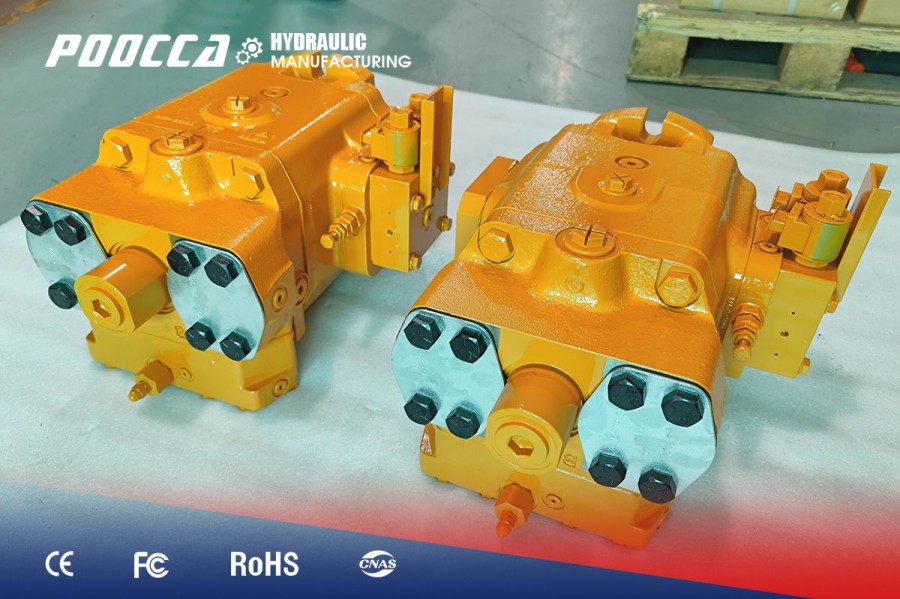

As a trusted global supplier, Poocca Hydraulics offers a wide range of variable displacement axial piston pumps.

Customized OEM/ODM Solutions.

Quick Shipments with verified pre-shipment photos.

12-month warranty and global support.

Poocca Hydraulic Manufacturer Real Customer Testimonials

A Polish customer operating an aluminum die-casting line said that after switching to Poocca variable displacement piston pumps:

System downtime was reduced by 60%.

Oil temperature stabilized at 42°C (previously 56°C).

They reduced oil changes from every 6 months to once a year.

“We thought a variable displacement pump would be too complicated. But the savings in power and cooling made us accept it without hesitation. Poocca also provided help with installation and commissioning.” – Customer Plant Maintenance Engineer

Conclusion: Is it worth it?

Absolutely. If your hydraulic system faces variable loads, precision requirements or long operating cycles, a variable displacement hydraulic piston pump is your best investment.

It provides precise control, efficiency and flexibility, making it the core of high-performance hydraulic systems in 2025 and beyond.

Purchase from Poocca now

Looking for a trusted supplier with reliable quality and fast delivery?

Poocca Hydraulic Manufacturer provides you with a one-stop solution for hydraulic pumps, motors, valves and accessories. We have major models in stock and support global shipments, now is the best time to upgrade your system.

Contact us for a quote, product catalog or custom technical consultation.

Hydraulic piston pump models such as A10VSO, A4VG, K3V and A11VLO are now ready for immediate shipment!

Post time: Jul-17-2025