In modern fluid power and hydraulic systems — from industrial lubrication loops to compact mobile hydraulic units — there is a growing demand for small, efficient, and reliable pumps. As hydraulic and fluid-handling applications diversify and become more compact, the role of small gear pumps (or “compact / small-displacement gear pumps”) becomes increasingly important.

At Poocca, we believe that understanding the true value and correct selection of a small gear pump can make a significant difference in system performance, reliability, and cost-effectiveness. That is why we are writing this article: to clarify what “small gear pump” really means, when and where it makes sense to use one, and what you should look for when selecting or specifying one for your system.

What Defines a “Small Gear Pump”

When we talk about a “small gear pump”, we are not referring to a vague idea, but to a class of gear-type positive-displacement pumps that meet certain practical size, flow, pressure and application-scope criteria. In the context of hydraulic and fluid-transfer systems (especially for compact or low-to-moderate flow requirements), small gear pumps occupy a useful niche between micro/micropumps (for lab or dosing) and large industrial pumps (for high-flow hydraulics or bulk transfer).

Here is a set of typical defining characteristics — i.e. a “reference envelope” — for small gear pumps, based on industry data and suppliers’ categorizations.

Typical Specification Range for Small Gear Pumps

| Parameter / Attribute | Typical Range or Definition for “Small Gear Pump”* |

|---|---|

| Flow Rate (discharge) | Roughly 1 to 50 GPM (≈ 4 to ~190 L/min) — as often classified by suppliers defining “small gear pump”. |

| Maximum Pressure / Pressure Capability | Up to ~3,500 psi (≈ 240 bar) in smaller/superior-design external gear pumps. |

| Volumetric / Overall Efficiency (under good conditions) | Typical volumetric efficiency in external gear pumps: ~85-95%; internal gear versions often deliver slightly higher volumetric efficiency. |

| Viscosity / Fluid Compatibility | Capable of handling standard hydraulic/lubricating oils; many small gear pumps can also handle moderately viscous or viscous fluids — depending on gear design, clearances, and materials. |

| Design & Size Suitability | “Small” here implies compactness: suitable for installations with limited space, or for systems where large flow is not needed but reliability and simplicity matter. Combined with above flow/pressure specs, distinguishes them from micro-dosing pumps (very low flow) or heavy-duty large-capacity pumps. |

* These ranges are approximate — actual “small gear pump” definition may shift depending on application, industry norms, and manufacturer classification.

What “Small” Means — Beyond Just Physical Size

The notion of “small” should not be reduced simply to physical dimensions. Instead, a “small gear pump” is best understood as a pump whose performance envelope (flow, pressure, displacement, duty-cycle) fits compact or moderate-duty fluid systems. In practice, “small gear pump” often implies:

-

Moderate flow (not bulk-transfer / high-volume pumping) — enough for lubrication loops, hydraulic circuits, oil transfer, chemical dosing, compact machinery, etc.

-

Pressure capacity sufficient for typical hydraulic or lubricating systems, but not necessarily for ultra-high-pressure large-scale hydraulic hydraulics.

-

Compactness: allowing installation where space is constrained, or where a small, efficient pump is preferred for integration in a larger system (e.g. mobile equipment, lubrication modules, compact hydraulic units, chemical dosing units).

-

Flexibility in fluid compatibility — with suitable gear design/materials, can handle a variety of media: oils, lubricants, moderately viscous fluids.

Comparison — External vs Internal Gear Pumps (for Small Gear Pump Applications)

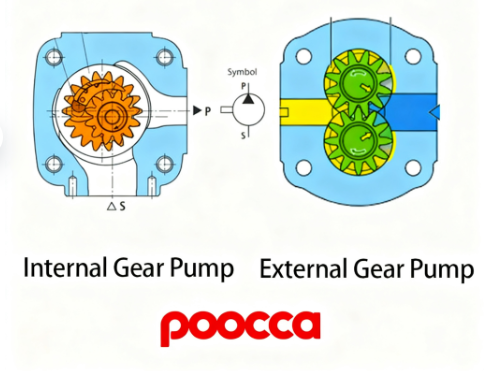

When selecting a small gear pump, one of the most important decisions is whether to choose an external-gear design or an internal-gear design. Although both operate on the same positive-displacement / gear-meshing principle, their structural differences lead to materially different performance, strengths and trade-offs. Below is a direct, data-oriented comparison and guidance for choosing between them.

Structural & Operational Differences

-

An external gear pump uses two identical external gears mounted side-by-side, each on its own shaft supported by bearings on both ends. Fluid is drawn into the expanding cavities at the inlet side created as the gears un-mesh, carried around the outer periphery of the gears, and then forced out as the gears mesh at the discharge side.

-

An internal gear pump uses a smaller inner “rotor” gear inside a larger outer “idler” gear. The inner gear drives the outer; a crescent or partition separates suction and discharge chambers, preventing back-flow. Fluid enters as the space between gear teeth expands, is carried in the chamber, and exits as the teeth mesh.

Because of these arrangements, external-gear pumps generally feature simpler geometry, whereas internal-gear pumps offer design flexibility (e.g. clearance adjustability, smooth flow path) that can benefit high-viscosity or demanding fluid applications.

External vs Internal — Key Attributes Compared

| Attribute / Criterion | External Gear Pump | Internal Gear Pump |

|---|---|---|

| Fluid viscosity / type suitability | Best for low to medium viscosity fluids (standard oils, lubricants, hydraulic fluids) — tight gear clearances ensure minimal internal leakage with such fluids. | Handles medium to high viscosity fluids well — more tolerant tolerances allow stable pumping of thicker oils, resins, adhesives, heavy oils, even viscous chemicals. |

| Pressure capability & speed | Good for medium-to-high pressure systems (many external gear pumps support hydraulic pressure ranges typical in hydraulic systems). | Usually used for medium pressures — while adequate for many industrial tasks, may be less ideal for very high-pressure hydraulics compared to an external-gear pump. |

| Flow smoothness, pulsation & noise | Delivers stable flow with relatively low pulsation compared to many pump types; but at high speeds the meshing of small external gears may introduce more noise / vibration compared to internal gear designs. | Typically quieter, smoother, and less pulsating — ideal for sensitive applications such as chemical dosing, metering, lubrication, or systems requiring stable flow at low-to-moderate speeds. |

| Tolerance to fluid contamination / solids / abrasion | Tight clearances + several bearings make external gear pumps sensitive to contamination or abrasive particles — contaminants can cause wear or damage and reduce lifespan. | More tolerant to viscous or somewhat contaminated fluids because of more relaxed clearances, but still not ideal for heavy solids or abrasive media — care is still needed. |

| Self-priming / suction / handling viscous / variable fluids | Can self-prime and pump many standard fluids; good suction for typical low-to-medium viscosity oils. However, with very viscous fluids, performance may degrade. | Generally has better suction and priming capability for viscous fluids, and handles variable or high-viscosity media more reliably. |

| Size, compactness, installation & maintenance cost | Typically simpler, more compact design; easier to manufacture, install, and maintain; cost-effective — good for general hydraulic or lubrication systems. | Design is more complex and manufacturing/maintenance cost tends to be higher; may be less compact in some configurations; but trade-off often justified when fluid type or operating conditions demand. |

Typical Applications for Small Gear Pumps

Small gear pumps — whether external- or internal-gear design — shine in a wide variety of applications, especially where flow, precision, compactness, or handling of viscous or specialty fluids is required. Below are the main use-cases and why small gear pumps are often a good (or best) choice.

Common Application Scenarios

| Application Area | Why Small Gear Pumps Work / What They Excel At |

|---|---|

| Lubrication & Oil Circulation | Small gear pumps are widely used in lubrication systems for machinery, gearboxes, engines, compressors, bearings, and other moving-part assemblies. Their positive-displacement design delivers a steady, metered flow of lubricating oil — crucial for consistent lubrication, wear reduction, and component longevity. |

| Compact Hydraulic & Mobile Fluid-Power Systems | For compact hydraulic power units, mobile machinery, lifting or actuation systems (especially where space is limited), small gear pumps offer a compact, robust, and efficient solution. They can deliver the needed pressure and flow without bulky pump assemblies. |

| Chemical / Petrochemical Processing & Chemical Dosing / Blending | When transferring, dosing or blending chemicals, solvents, additives, polymers, or other reactive media — small gear pumps (with appropriate material selection) provide precise, constant flow, good pressure handling, and compatibility with viscous or moderately aggressive fluids. |

| Viscous Fluids, Resins, Polymers, Heavy Oils, Adhesives | Internal-gear small pumps in particular excel with high-viscosity media — resins, heavy oils, bitumen/asphalt, adhesives, waxes etc. Because gear-meshing positive-displacement works similarly regardless of viscosity (within design limits), they can move thick, viscous fluids reliably. |

| Metering, Dosing, and Precise Flow/Volume Control | Since gear pumps deliver a fixed volume per revolution and flow is proportional to rotational speed, small gear pumps are ideal for applications requiring accurate dosing — chemical additive injection, food- or chemical-grade mixing, paint/ink metering, small-volume dispensing. |

| Food, Beverage, Cosmetics, and Hygiene-Sensitive Industries (with proper materials) | When built with sanitary or corrosion-resistant materials (e.g. stainless steel), small gear pumps are used in food-grade, beverage, cosmetics, and personal-care production — for syrups, oils, lotions, chemical additives — especially where accurate, clean, and consistent flow is required. |

| Small-Batch / OEM / Compact Equipment / Filling & Packaging Lines | Their compactness, tight tolerances, and controllable flow make small gear pumps suitable for OEM machines, filling machines, small-batch production lines, packaging equipment, lab-scale dosing, or any context where space and precision matter more than bulk flow. |

What to Watch Out For — When Small Gear Pumps May Not Be Suitable

Despite their strengths, small gear pumps have limitations, and they’re not universally ideal. Key constraints include:

-

Need for clean, non-abrasive fluids — gear pumps rely on tight clearances and smooth meshing; contaminated, abrasive, or particle-laden fluids will accelerate wear and reduce lifespan.

-

Not ideal for extremely high flow or bulk transfer — if the system requires very high flow rates (e.g. bulk fluid transfer, high-volume circulation), a small gear pump may be undersized. Larger displacement pumps or other pump types may be more appropriate.

-

Temperature / fluid-property limitations — certain fluids (very abrasive, highly corrosive, extremely viscous beyond pump design limits) may require special material construction or alternative pump types.

-

Maintenance / wear sensitivity — small displacement and tight tolerances imply that wear, seal degradation, or insufficient fluid cleanliness / filtration can significantly shorten service life or impair performance.

Key Selection Criteria — How to Choose the Right Small Gear Pump

When selecting a small gear pump for a given application, it’s essential to match the pump specifications carefully to the demands of the fluid, system, and operating conditions. Below are the main criteria you should evaluate, and practical guidance on how to apply them.

Key Factors to Evaluate

| Selection Factor | Why It Matters / What to Check |

|---|---|

| Fluid Properties — Viscosity, Chemistry, Solids / Cleanliness | The fluid’s viscosity, chemical compatibility, and contamination level are fundamental. Gear pumps rely on tight internal clearances; low‑viscosity fluids may cause excessive internal “slip” (backflow through clearances), decreasing volumetric efficiency. If fluid is high-viscosity (e.g. heavy oils, viscous resins), the pump must be designed to handle that – possibly with modified clearances, lower speed, or internal‑gear design. For corrosive or chemically aggressive fluids, material compatibility (housing, gears, seals) is crucial; otherwise corrosion or seal failure may occur. |

| Flow Rate Requirement | The required flow (volume per time) determines the pump displacement (gear size, volume per revolution) and the operating speed. You must ensure the pump’s nominal displacement × speed can meet the system demand. |

| Pressure (Differential / System Pressure) | Because gear pumps are positive displacement, flow is relatively independent of pressure (unlike centrifugal pumps). But higher system pressure increases torque load, sealing demand, and mechanical stress — pump design (gear strength, housing materials, relief valves) must match or exceed required system pressure. |

| Operating Temperature & Fluid Temperature | Fluid temperature impacts viscosity — as temperature rises, viscosity drops; as temperature falls, viscosity increases. If fluid is pumped hot (or cold), the pump materials (housing, seals, gears) must withstand thermal conditions; pump clearances or seal materials may need adjustment to maintain performance/stability. |

| Compatibility of Materials & Seals with Fluid | The wetted parts (gears, housing, bearings, seals) must resist chemical attack, corrosion, abrasion, temperature — depending on fluid properties (chemicals, solvents, oils). For aggressive or corrosive fluids, consider stainless steel, special alloys, or chemically resistant materials; for standard oils/lubricants, cast iron or standard alloys may suffice. |

| Cleanliness / Filtration & Solid / Particle Content | Gear pumps have tight tolerances; presence of solid particles, abrasives, or contaminants can cause accelerated wear, leakage, decreased lifespan, or failure. For fluids with possible particulates, ensure proper filtration / strainer (mesh size) upstream, and design for maintenance/replacement. |

| Required Pump Speed / Motor Power & Torque | For viscous fluids or high viscosity media, the pump may need lower speed to allow fluid to “fill” gear cavities; higher viscosity increases torque demand. Ensure motor/drive selected matches torque requirement at required pressure and viscosity; using underpowered drives may cause gear tooth failure or motor overload. |

| Pump Type (External Gear vs Internal Gear vs Others) | Depending on fluid viscosity, pressure, flow, maintenance, and application, choose appropriate pump type. For standard oils or medium-viscosity fluids at moderate/high pressure — external gear may suffice. For high-viscosity fluids, viscous chemicals, adhesives, or media requiring gentle handling — internal gear or specialized gear pump designs may perform better. |

| Maintenance, Service Life & Lifecycle Cost | Consider not only upfront cost, but also maintaining cleanliness (filtration), replacement of wear parts (gears, seals), energy consumption (affected by viscosity, pressure, slip), and downtime cost. If fluid or environment is challenging (abrasive, corrosive, high temp), choose higher‑quality materials, better seals, or possibly custom design — this may increase upfront cost but save maintenance and extend life. |

| Compliance with Application Requirements (e.g. chemical resistance, food‑grade, safety, temperature, noise, space constraints) | The pump must meet application-specific requirements — e.g. sanitary/food‑grade material if used in food/beverage/cosmetic; corrosion resistance for chemical; noise/compactness for OEM or mobile equipment; limited installation space; regulatory compliance. |

Common Misconceptions & Pitfalls — What Many Overlook

Even though gear pumps (including small gear pumps) are widely used and praised — compact, simple, reliable — there are many frequent misunderstandings, hidden limitations or operational risks that are often under‑emphasized. Ignoring these can result in poor performance, frequent failures, or short service life. Below is an honest, realistic evaluation of common pitfalls, and how to avoid them.

Typical Misconceptions vs What Actually Happens

| Misconception / Simplification | Reality / Risk / What to Watch Out For |

|---|---|

| “Gear pumps can pump any fluid reliably — low viscosity, high viscosity, even solvents or thin liquids.” | Not true. Because of the tight internal clearances (gear‑to‑housing, gear‑to‑gear, end plates), if the fluid is very low viscosity (e.g. thin solvents), a substantial portion will “slip” (internal leakage) from discharge to suction side. That reduces real output flow and volumetric efficiency sharply.Also, thin fluids may provide poor lubrication inside the pump, accelerating wear. |

| “Higher viscosity fluids are always better — more efficient, less leakage.” | While higher viscosity can reduce slip, too‑high viscosity introduces new problems: increased friction torque, higher power/torque demand, possible difficulty in self-priming or startup (especially cold or “thick” fluids), increased heat generation, and wear/stress on gears and bearings. |

| “Once you install a gear pump and it runs, performance remains stable forever.” | Over time, internal wear (gear teeth, side plates, bearings) will enlarge internal clearances; as clearances grow, slip increases, volumetric efficiency decreases, real output drops — sometimes gradually then abruptly once a critical wear threshold is reached. |

| “Gear pumps are maintenance‑free, cheap and simple.” | While simpler than some pump types, gear pumps still require precise tolerances, good fluid cleanliness, proper lubrication, periodic inspection. If these are neglected — e.g. fluid contamination, poor filtration — abrasion and wear accelerate.Also, for small pumps, repairability may be limited: worn internal parts may not be replaceable or cost‑effective. |

| “You can run a gear pump dry or with intermittent flow — no problem.” | Gear pumps generally rely on the pumped fluid itself for lubrication and cooling of gears and bearings. Running dry or operating with poor fluid supply can cause rapid bearing or gear damage, overheating, seizure or irreversible failure. |

| “Gear pump displacement / flow / pressure are flexible and were easy to adjust.” | Most gear pumps are fixed‑displacement: you get a fixed volume per revolution. Flow scales with speed; pressure is constrained by design. To change flow or pressure requires external controls (variable-speed drive, relief valves etc.) — you cannot easily “tune” output internally. |

Conclusion & Call to Action

Small gear pumps — when properly understood, selected and applied — offer a powerful combination of compactness, efficiency, reliable flow, and flexibility for a wide variety of hydraulic and fluid‑handling systems. But they are not magic: their performance depends heavily on fluid properties, cleanliness, correct design, and maintenance discipline.

If you are considering a small gear pump for lubrication systems, compact hydraulic units, oil transfer, chemical or viscous‑fluid transfer, dosing/ metering, or other applications — make sure you assess the fluid, pressure, flow, viscosity, temperature, contamination risk, and maintenance conditions carefully.

At Poocca, we are ready to work with you: analyze your application requirements, recommend the right pump type (external vs internal), suggest optimal materials and clearances, and provide maintenance/operation guidance.

Contact us today — let’s discuss your system, define your requirements, and provide a tailored small gear pump solution that balances performance, reliability, and cost.

Post time: Nov-27-2025