Operation and Maintenance of 4WE Hydraulic Valve

Introduction

Hydraulic systems are widely used in industrial and commercial applications. These systems consist of various components, including hydraulic valves. The 4WE hydraulic valve is a popular type of hydraulic valve that is used in various applications. In this article, we will discuss the operation and maintenance of the 4WE hydraulic valve.

Understanding the 4WE Hydraulic Valve

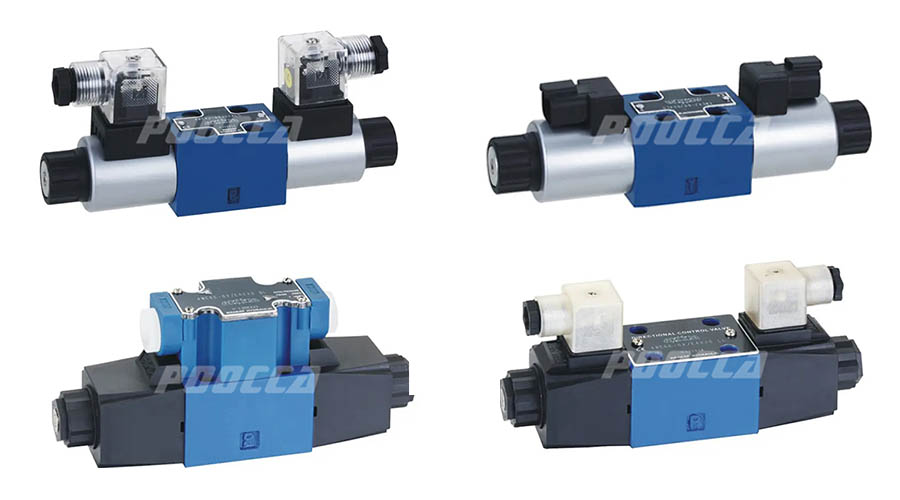

The 4WE hydraulic valve is a directional control valve that controls the flow of hydraulic fluid in a hydraulic system. This valve is manufactured by Bosch Rexroth, a leading company in the hydraulic industry. The 4WE hydraulic valve is designed to operate at high pressures and is suitable for use in a wide range of hydraulic applications.

Types of 4WE Hydraulic Valve

There are several types of 4WE hydraulic valves available in the market, including:

- 4WE6 Hydraulic Valve

- 4WE10 Hydraulic Valve

- 4WEH Hydraulic Valve

Each of these valves is designed for specific applications and has different specifications.

Operation of 4WE Hydraulic Valve

The 4WE hydraulic valve operates by controlling the flow of hydraulic fluid in a hydraulic system. The valve has four ports, including two inlet ports and two outlet ports. The inlet ports are connected to the hydraulic pump, while the outlet ports are connected to the hydraulic cylinder or motor.

Working Principle

The 4WE hydraulic valve operates on the principle of spool movement. The valve has a spool that is moved by the hydraulic pressure in the system. When the spool is moved, it opens or closes the valve ports, allowing or blocking the flow of hydraulic fluid in the system.

Valve Positions

The 4WE hydraulic valve has different positions, including:

- Neutral Position: In this position, all the ports of the valve are blocked, and there is no flow of hydraulic fluid in the system.

- P Position: In this position, the A port is connected to the B port, and the T port is blocked. This allows the hydraulic fluid to flow from the pump to the cylinder or motor.

- A Position: In this position, the A port is connected to the T port, and the B port is blocked. This allows the hydraulic fluid to flow from the cylinder or motor to the tank.

- B Position: In this position, the B port is connected to the T port, and the A port is blocked. This allows the hydraulic fluid to flow from the tank to the cylinder or motor.

Maintenance of 4WE Hydraulic Valve

Proper maintenance is essential to ensure the optimal performance of the 4WE hydraulic valve. Regular maintenance can help to prevent breakdowns and extend the lifespan of the valve.

Inspection

Regular inspection of the 4WE hydraulic valve is necessary to detect any signs of wear and tear. The valve should be inspected for leaks, cracks, and corrosion. Any damaged parts should be replaced immediately to avoid any further damage to the valve.

Cleaning

The 4WE hydraulic valve should be cleaned regularly to remove any dirt or debris that may clog the valve ports. The valve can be cleaned using a suitable cleaning solution and a soft cloth. Care should be taken not to damage the valve during cleaning.

Lubrication

Proper lubrication is essential to ensure the smooth operation of the 4WE hydraulic valve. The valve should be lubricated regularly using a suitable lubricant. Over-lubrication should be avoided as it can cause the valve to malfunction.

Replacement

The 4WE hydraulic valve should be replaced if it is damaged beyond repair. Replacement parts should be purchased from a reliable supplier to ensure the quality and compatibility of the parts.

Post time: Apr-24-2023