In the hydraulic industry, “Does the hydraulic piston pump belong to the pneumatic or hydraulic system?” This question seems simple, but beginners who have just come into contact with the product or users with non-engineering backgrounds may be confused. We will introduce the working principle, system affiliation, and technical advantages of hydraulic piston pumps, and introduce the high-quality piston pump solutions provided by Poocca hydraulic manufacturers to help you clarify the direction of purchase.

Poocca hydraulic manufacturers sell hydraulic piston pump products, which can 100% replace the original Rexroth, Vickers, Parker, Yuken, Eaton and other brands. If you have any needs, please contact us.

1. Hydraulic piston pumps are hydraulic equipment, not pneumatic equipment

First and foremost, the conclusion is sure: Hydraulic piston pumps (Hydraulic Piston Pumps) are hydraulic equipment, not pneumatic equipment.

1.1 Hydraulic and pneumatic differentiation

Classification Hydraulic system Pneumatic system

Driving medium Liquid (e.g., hydraulic oil) Gas (e.g., compressed air)

Pressure range High (common 100-420 bar) Low (common 6-10 bar)

Control accuracy High, suitable for heavy loads Low, suitable for light loads

Application areas Engineering machinery, injection molding machines, ships, etc. Automation, packaging equipment, light industry

1.2 The nature of function of hydraulic piston pumps

Hydraulic piston pumps utilize hydraulic oil as work medium and carry out energy conversion by the reciprocating movement of the plunger in the pump cylinder, and convert mechanical energy into hydraulic energy and supply high-pressure fluid flow to the hydraulic system.

It can deliver high pressure and high flow, which is very suitable for severe industrial applications such as construction machinery, farm vehicles, mining equipment, and injection molding machines.

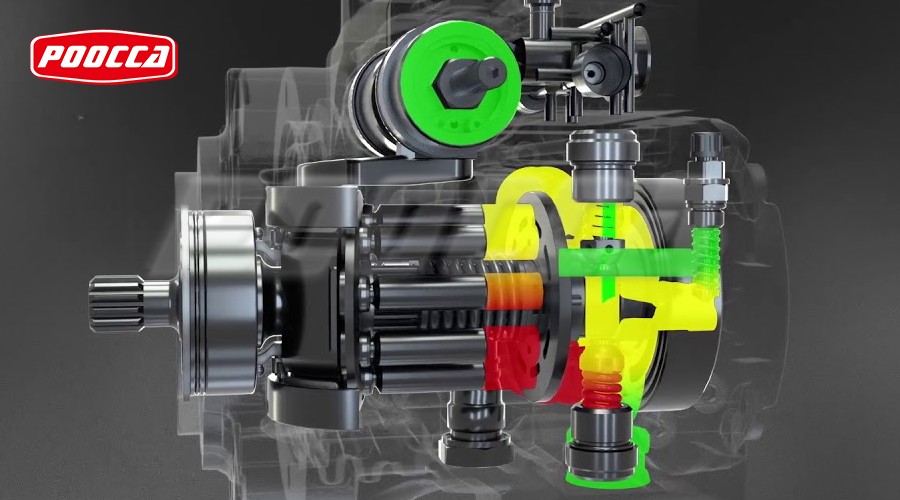

2. Explanation of the working principle of hydraulic piston pumps

Hydraulic piston pumps mainly have axial piston structure or radial piston structure, and can be divided into fixed displacement pumps and variable displacement pumps according to the mode of displacement. The following is a brief introduction to the hottest model of Poocca as an example.

2.1 Axial Piston Pump

Take Poocca A10VSO series as an example:

Swash plate structure design: By adjusting the angle of the swash plate to change the plunger stroke, variable control is achieved;

Displacement range: 16~180 cc/rev;

Pressure: The maximum working pressure is 350 bar, and the peak pressure can reach 420 bar;

Applicable scenarios: Widely used as the power source of engineering vehicles and hydraulic machinery and equipment.

2.2 Brief description of the working process

The motor drives the drive shaft to rotate;

The plunger reciprocates in the cylinder;

The oil inlet and outlet are controlled by the oil distribution plate;

The oil suction and discharge process is completed;

Stable high-pressure liquid flow is output for system use.

This closed or open loop structure makes it more suitable for high-pressure and multi-function control systems than gear pumps and vane pumps.

3. Technical highlights of Poocca hydraulic piston pumps

Poocca Hydraulic Manufacturer is a leading hydraulic pump manufacturer in China, focusing on providing hydraulic piston pumps with reliable performance, solid structure and high cost performance. Our products cover the following series:

Super strong pressure-resistant structure: using high-strength alloy cylinder and surface heat-treated plunger, excellent wear resistance;

Precise variable control: support pressure compensation, load sensing, electro-hydraulic proportional control;

Long life design: key components have a life of more than 5000 hours;

Strong adaptability: support SAE standard interface, compatible with multiple brands.

4. Poocca Hydraulic Manufacturer – Your Trustworthy Hydraulic Partner

4.1 Company Profile

Poocca Hydraulic Manufacturer is a company focusing on the research and development, production and export of hydraulic pumps, motors, valve groups and power units, with more than 20 years of industry experience. The factory is equipped with advanced CNC machining centers, automatic test benches, and clean assembly workshops.

4.2 Service Advantages

Sufficient stock and stable delivery: Most models are in stock for a long time, supporting fast delivery;

Support OEM/ODM customization: Flange interfaces and control logic can be customized according to customer requirements;

Rich global export experience: serving customers in North America, Europe, Southeast Asia, the Middle East and other places;

Professional technical support team: assist in selection, system design, and troubleshooting.

5. Typical application cases of hydraulic piston pumps

5.1 Construction machinery

Such as excavators, bulldozers, cranes;

Using K5V/K7V series double variable piston pumps, the operation can be precisely controlled;

Poocca customer feedback: “Compared with original imported products, Poocca replacement parts are cost-effective and have a long life.”

5.2 Injection molding and pressure equipment

Poocca A4VSO pump is compatible with Rexroth;

Proportional variable control can be provided;

Applied to plastic machinery hydraulic stations and hydraulic presses.

5.3 Mobile hydraulic equipment

Tractors, combine harvesters, forest harvesting equipment;

Provide low-noise, high-sealing, anti-pollution hydraulic pump structures.

6. Common misunderstandings: Why are piston pumps mistakenly considered pneumatic devices?

Many non-professionals tend to think of “pneumatic piston cylinder” when they first come into contact with the word “piston”, so they mistakenly think that piston pumps are pneumatic devices. In fact, pneumatic piston devices are more common in automated clamping devices, while hydraulic piston pumps are dedicated to high-load systems.

Correct understanding method:

Observe the working medium: pneumatic uses air, hydraulic uses hydraulic oil;

Look at the application scenario: if the equipment needs to output large torque or thrust, it must be a hydraulic system;

Identify the connection interface: hydraulic pumps mostly use standard parts such as SAE flanges and high-pressure oil pipes.

7.Procurement suggestions: How to choose a suitable hydraulic piston pump?

Clear system pressure and flow requirements

If the system requires a pressure of more than 250bar, it is recommended to choose variable pumps such as Poocca A10VSO/A4VSO;

Judge the control method

Is it a quantitative system or does it require load sensing and pressure compensation control;

Installation interface matching

Flange standards, drive shaft types, etc. must be compatible with the original system;

Presence of spare parts and after-sales

Choose professional factories like Poocca to ensure long-term supply and technical support.

8.Conclusion and procurement

**Hydraulic piston pumps are the fundamental parts of hydraulic systems, not pneumatic equipment. **If you are looking for high-quality, reliable and long-lasting hydraulic piston pump products, whether it is to replace Rexroth, Kawasaki, Parker, or to use in your system, Poocca Hydraulic Manufacturer is your best choice.

Post time: Jul-04-2025