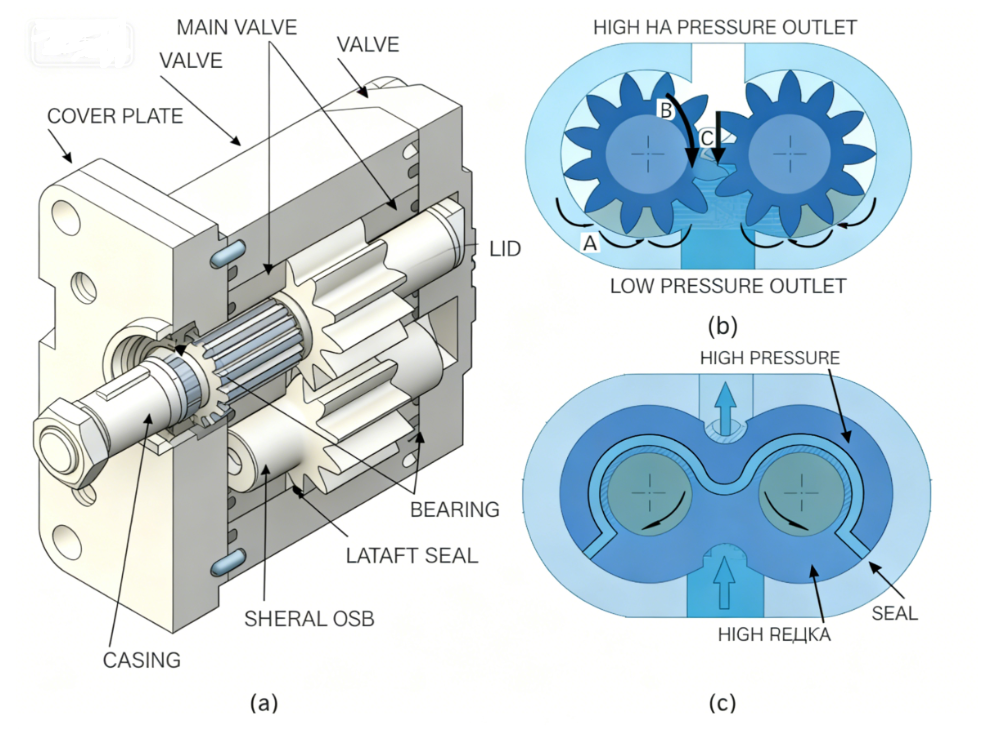

In modern industrial and mechanical systems, the hydraulic gear pump is a fundamental component — compact, reliable and versatile, it plays a central role in fluid power transmission and hydraulic power systems. A gear pump works by two meshing gears rotating inside a precisely machined housing: fluid is drawn into the inlet as the gear teeth separate, then carried around the gear periphery or between inner/outer gears, and finally discharged through the outlet as the teeth mesh again. Depending on the gear arrangement and internal configuration, gear pumps are broadly classified into external-gear and internal-gear types, each offering advantages under different operational requirements.

This article aims to go beyond a superficial overview. We intend to guide engineers, procurement managers, system integrators and OEMs through the critical process of selecting appropriate hydraulic gear-pump suppliers: evaluating cost vs value, understanding the real technical trade-offs, avoiding common misunderstandings, and ultimately helping readers make informed decisions or engage in further consultation.

Global & Industry-wide Context

The market for hydraulic gear pumps continues to grow steadily worldwide, driven by rising demand across multiple industrial and mobile‑machinery sectors. Recent market reports provide a clear picture:

-

According to a 2025 report by Global Market Insights, Inc., the global hydraulic gear pumps market is projected to reach about USD 3.7 billion by 2032.

-

Another source from Future Market Insights estimates the 2025 market value at roughly USD 2.1 billion, with growth to around USD 3.0 billion by 2035, implying a ~3.7% compounded annual growth rate.

-

The demand is primarily driven by increasing industrial automation, expanded construction and infrastructure development, growth in agriculture mechanization, and rising adoption of efficient hydraulic systems in mobile machinery and material‑handling equipment.

-

From a regional perspective, markets in North America, Europe, and Asia‑Pacific are among the strongest contributors, reflecting broad use in developed and emerging economies alike.

Key Trends & Demand Drivers

-

Industrial automation and equipment modernization: As factories, manufacturing lines, and heavy‑equipment producers modernize, there is greater reliance on robust hydraulic systems. Gear pumps — being relatively simple, reliable, and cost‑effective — remain a cornerstone technology for many such systems.

-

Growth in construction, agriculture, and infrastructure sectors: Excavators, loaders, tractors, cranes, material‑handling machines — all rely heavily on hydraulic gear pumps. The expansion of infrastructure and agriculture mechanization spurs gear pump demand worldwide.

-

Demand for cost‑effective, reliable fluid‑power solutions: Compared to some variable‑displacement or more complex pump types, gear pumps offer a favorable balance of reliability, ease of maintenance, and lower total cost of ownership, making them attractive especially for heavy‑duty, stable‑load applications.

-

Regional manufacturing and export/import dynamics: Regions with strong manufacturing bases (e.g. North America, Europe, parts of Asia‑Pacific) both consume and supply hydraulic gear pumps. This geographic diversity helps ensure supply resilience and a wide selection of pump types and quality levels for buyers worldwide.

Representative Gear Pump Suppliers / Manufacturers

In the global market for hydraulic gear pumps, several suppliers and manufacturers are widely recognized for their product quality, engineering capability, reliability, and broad market coverage. Below are some of the most representative companies — recommended for OEMs, system integrators, and buyers seeking either standard or custom gear‑pump solutions — along with their strengths and typical use cases:

| Supplier / Manufacturer | Origin / Region / Background | Key Strengths & Typical Application Scenarios |

|---|---|---|

| Bosch Rexroth AG | Germany / Global | Known for precision engineering and high-quality manufacturing; their gear pumps are widely used in industrial automation, manufacturing equipment, and mobile‑hydraulic systems requiring reliability and long service life. |

| Parker Hannifin Corporation | USA / Global | Offers a broad product range; its pumps serve agriculture machinery, construction equipment, industrial hydraulics, and mobile‑equipment sectors — with good availability and global support network. |

| Eaton Corporation plc | Global (international firm) | Known for robust, heavy‑duty hydraulic solutions; gear pumps from Eaton are suitable for demanding industrial and mobile‑equipment applications where durability and integration matter. |

| Casappa S.p.A. | Italy / Europe / Global export | Provides compact and modular gear‑pump solutions — often chosen where space is constrained or where customized pump configurations are needed (e.g. special mounting, compact hydraulic units). |

| Bucher Hydraulics GmbH | Germany/Switzerland Europe / Global market | Specialized in mobile and industrial hydraulics; their pumps are well‑regarded for reliability and suitability in mobile machinery, construction equipment, or industrial hydraulic systems. |

| Linde Hydraulics GmbH & Co. KG | Germany / Worldwide service | Focus on heavy‑duty drive systems, including hydraulic pumps and motors, power‑transmission components — suitable when comprehensive hydraulic system integration is needed. |

| Kawasaki Heavy Industries Ltd. | Japan / International export | Has a track record in supplying gear pumps for heavy‑duty applications — construction machinery, mobile equipment, where ruggedness and reliability under load matter. |

| Regional / OEM / Custom Suppliers (e.g. your company, “Poocca” / similar manufacturers) | China or other global‑export capable regions | These suppliers excel in flexibility, offering standard gear pumps as well as customizable options (displacement, mounting interface, materials, sealing, etc.), which is ideal for clients with special requirements or OEM/ODM sourcing needs. Such suppliers often provide cost‑effective, tailor‑made solutions, especially for non‑standard or specialized applications. |

How to Choose the Right Supplier

Recommended Decision‑Making (Comparison & Selection) Process

Here is a practical step‑by‑step method for selecting the right gear pump and supplier:

| Step | Action |

|---|---|

| 1 | Define system hydraulic requirements: required flow (L/min / GPM), required pressure (max/average), fluid type (viscosity, temperature, chemical properties), operating conditions (environment, duty cycle) |

| 2 | Shortlist potential pumps & suppliers whose published specs roughly match the requirements (displacement, max pressure, fluid compatibility, speed range) |

| 3 | Request from supplier: full spec sheet, performance curve (flow vs pressure), materials & sealing specifications, recommended fluid types, expected efficiency / volumetric efficiency, recommended maintenance intervals |

| 4 | Compare shortlisted options by “fit‑to‑purpose” criteria: technical match, expected service life, maintenance ease, supplier reliability and spare‑parts support, total cost of ownership (initial cost + maintenance + downtime risk) |

| 5 | If demands are special (e.g. high viscosity fluids, unusual porting, custom installation), verify supplier’s customization capabilities and request samples or prototype pump for testing |

| 6 | Choose supplier/pump — for critical or long‑life systems, prioritize quality & support; for cost‑sensitive or non‑critical use, balance performance vs cost carefully |

| 7 | Document the selection (system requirements, pump specs, supplier info, maintenance schedule) — for future maintenance, troubleshooting, and consistency across procurement |

Common Pitfalls & Mistakes in Pump Selection

-

Selecting based solely on displacement or nominal flow, without considering system pressure, fluid viscosity, or operating conditions — may result in inefficiency or early failure.

-

Overlooking internal leakage and volumetric efficiency — especially at higher pressures or with less‑viscous fluids. Gear pumps naturally have some slip; performance curves and efficiency data must be reviewed.

-

Ignoring maintenance and spare‑parts availability when choosing low‑cost or obscure suppliers — can lead to long downtime or inability to repair.

-

Failing to account for real duty‑cycle and operating environment (e.g. temperature, fluid type, contamination) — what “works on paper” may fail in real conditions.

-

Treating all gear pumps as equal — differences in design, tolerances, materials, sealing, machining precision and manufacturer quality can lead to huge differences in performance, efficiency, and lifetime.

Common Misconceptions & Risks

Despite the widespread use and praise for gear pumps, there are a number of common misunderstandings, hidden limitations, and operational risks that are often under‑emphasized. Overlooking these can lead to sub‑optimal performance, frequent failures, or shorter service life. Below are the key misconceptions and the corresponding realities.

Misconceptions vs Reality

| Misconception / Simplification | Reality / Risk / What to Watch Out For |

|---|---|

| “Gear pumps can reliably pump any fluid — low viscosity, high viscosity, even thin solvents or aggressive fluids.” | Not true. Because gear pumps rely on tight internal clearances (gear‑to‑gear, gear‑to‑housing, end plates), very low‑viscosity fluids (e.g. thin solvents) tend to “slip” (internal leakage) from the discharge side back to suction, significantly reducing real output flow and volumetric efficiency. Also, thin fluids often provide poor lubrication, which accelerates wear. |

| “Higher viscosity fluids are always better — more efficient and less leakage.” | While higher viscosity fluids can reduce slip, overly viscous fluids (or fluids with poor flow characteristics at low temperature) may cause high friction, increased torque/power demand, difficulty in self‑priming or startup (especially under cold conditions), heat buildup, and accelerated wear on gears and bearings. This can degrade performance or cause premature failure. |

| “Once installed, gear pump will run for a long time without maintenance — it’s cheap and simple.” | Not necessarily. Although simpler than some high‑complexity pumps, gear pumps still require proper fluid cleanliness, correct lubrication, periodic inspection (gears, bearings, seals), and maintenance. Neglecting maintenance — especially in harsh environments or with contaminated fluids — will accelerate wear, increase leakage, and reduce volumetric efficiency or even cause failure. |

| “Gear pumps can run dry or with intermittent flow — it’s no problem.” | That assumption is risky. Gear pumps generally rely on the pumped fluid for lubrication and cooling of internal parts (gears, bearings, seals). Running dry, or with inadequate fluid supply, can cause overheating, rapid wear, seizure, or irreversible damage. |

| “Flow rate / pressure / output of gear pumps is flexible and easily adjustable by the pump itself.” | Most gear pumps are fixed‑displacement — they deliver a set volume per revolution. Flow may vary with speed, but pressure and flow adjustments require external controls (e.g. variable‑speed drives, relief valves). You can’t “tune” the displacement internally. For systems needing variable flow or precise control, gear pumps may not be ideal without extra components. |

Conclusion & Call‑to‑Action

Choosing the right hydraulic gear pump and supplier is not a trivial procurement decision — it’s a strategic decision that impacts the performance, reliability, maintenance cost, and total lifecycle value of your hydraulic system. Gear pumps offer many advantages: compact size, relatively simple construction, ease of maintenance, cost‑effectiveness, and stable flow delivery under the right conditions.

However, gear pumps are not a universal solution. They have limitations: fixed displacement (so limited flexibility for variable flow demands), susceptibility to wear when handling abrasive or contaminated fluids, potential internal leakage or efficiency reduction over long-term use, and constraints when very high pressure or precise flow control is required.

Therefore — the best practice is to match pump and supplier to your actual system requirements, and to evaluate not only the upfront purchase cost, but the full picture: compatibility with fluid/viscosity, maintenance cycle, spare‑parts availability, expected duty cycle, and long‑term reliability.

If you are currently evaluating gear‑pump suppliers, or planning to source gear pumps for a new project — we encourage you to contact us at Poocca.

We can offer:

-

Standard gear‑pump solutions suitable for typical hydraulic systems

-

Custom OEM / ODM pumps tailored to your specific parameters: flow, pressure, fluid type, mounting interface, sealing requirements, etc.

-

Reliable documentation, spare‑parts support, and after‑sales service — helping you minimize downtime and reduce total cost of ownership

Take the next step: gather your system requirements (flow/pressure/working fluid/installation constraints) and reach out — we’ll help you identify the optimal gear pump solution and supply plan.

FAQ

Q1: What types of fluids can a hydraulic gear pump handle?

A: Gear pumps perform well with many fluids — especially hydraulic oils and other lubricating liquids. They also can handle moderately viscous fluids.

However, gear pumps are not ideal for very low‑viscosity fluids (thin solvents) — internal leakage (“slip”) may become significant — nor for fluids containing abrasive particles or corrosive chemicals unless the pump is built with appropriate materials and sealing.

Q2: Can gear pumps deliver variable flow or variable output pressure?

A: Standard gear pumps are fixed‑displacement — they deliver a fixed volume per revolution, so flow is roughly proportional to speed, and pressure capability is limited by design.

If your system requires variable flow or pressure — e.g. variable actuator speed — gear pumps alone may not be sufficient. You would need external components (e.g. variable-speed drive, flow/pressure control valves) or consider other pump types better suited for variable-output applications.

Q3: Are gear pumps suitable for high‑pressure or heavy‑duty applications?

A: Gear pumps can handle moderate pressures — many are rated up to several hundred bar (depending on design).

However, compared to piston pumps or variable‑displacement pumps, gear pumps have limitations under very high pressure, heavy workloads, or abrupt pressure/flow changes.

Q4: What maintenance or care is required to keep a gear pump operating reliably?

A: Key tasks include: ensuring hydraulic fluid is clean (free of abrasives/contaminants), using fluid with appropriate viscosity and temperature, checking and replacing seals or bearings if wear appears, and avoiding dry‑run or inadequate fluid supply (which can cause internal damage).

Additionally, correct installation, proper suction & discharge line design (to avoid cavitation), and adhering to recommended operating speeds/fluids help ensure longevity and stable performance.

Q5: How to choose a reliable gear pump supplier or manufacturer? What to pay attention to?

A: Consider the following when evaluating suppliers:

-

Whether they provide complete technical documentation (datasheets, materials spec, performance curves).

-

Their ability to supply spare parts, wear parts, and long‑term after‑sales support.

-

Manufacturing quality: material selection, machining/tolerance precision, sealing quality — these influence pump lifespan and performance.

-

Flexibility to provide custom or OEM/ODM solutions (if your application has special requirements for flow, pressure, fluid type, mounting, etc.).

Post time: Dec-10-2025