Hydraulic track motors are the unbemed heroes of the construction, mining, agricultural, and material handling industries, driving everything from crawler loaders to excavators. Motors that convert hydraulic energy to rotational torque drive heavy tracks and enable machines to move seamlessly over dirty, sandy, gravel, or rocky terrain.

Understanding how a hydraulic track motor works is more than an engineering curiosity—it’s an indicator of equipment performance, reliability, and cost of ownership for equipment makers, dealers, and purchasing managers.

1. What is a Hydraulic Track Motor?

Hydraulic track motor is a hydraulic motor whose main role is to drive the track system of a mobile machine. It is part of the final drive system, where pressurized oil from the major hydraulic pump is utilized to be converted to rotary motion to drive the tracks.

Some common uses are:

Excavators (small, medium, and large); Bulldozers and crawler tractors; Drilling rigs; Forestry harvesters; Crawler agricultural equipment; Road planers

In contrast to conventional hydraulic motors, crawler motors are capable of withstanding high torque at low speeds and frequently work outdoors under adverse conditions.

2. Core Operating Principle

Hydraulic track motors operate around hydraulic energy conversion:

The hydraulic pump generates pressure—the machine’s main hydraulic pump (typically an axial piston pump) draws oil from the reservoir and pressurizes it.

Pressure is generated by the hydraulic pump—the main hydraulic pump of the machine (generally an axial piston pump) sucks oil from the reservoir and pressures it.

The pressurized oil is delivered to the track motor—a hydraulic control valve delivers high-pressure oil to the track motor inlet.

The motor converts the pressure into rotation—inside the motor, the pressure is applied to pistons, vanes, or gears (depending on design), creating rotational force on the output shaft.

The final drive gear reducer—the output shaft is married to a planetary gear set, which reduces speed and multiplies torque before sending power to the sprockets.

The tracks propel the machine—the sprockets interface with the track links, propelling the machine in a forward or reverse direction.

The operator controls this pressure-to-motion process using joysticks or pedals, allowing the hydraulic system to instantly adjust speed and direction.

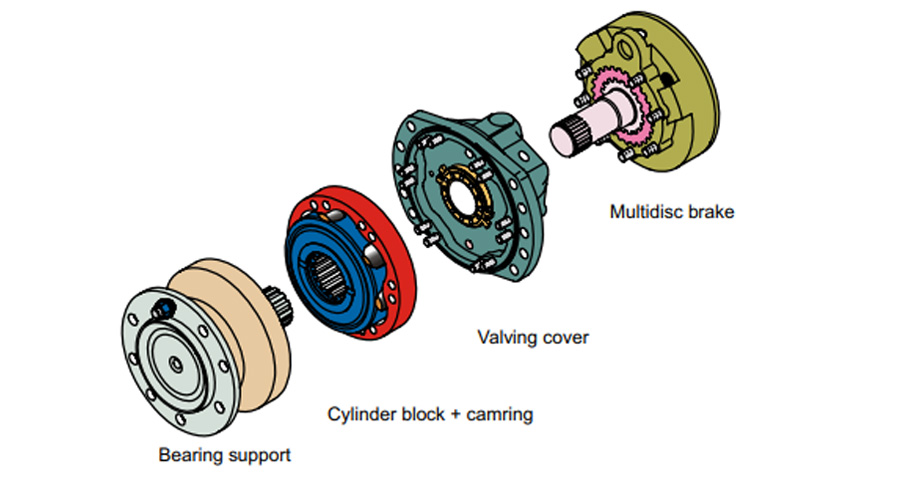

3. Internal Components of a Hydraulic Track Motor

To ensure long-term, stable operation under harsh operating conditions, the internal structure of a hydraulic track motor has been specially designed. It consists of the following core components:

Motor Housing

Made of high-strength alloy steel or ductile iron, it can withstand high pressure and shock loads.

The housing also serves as a channel for the hydraulic oil and protects the precision components within from external contamination.

Rotating Group

For plunger motors: This consists of the cylinder, piston, swash plate, and oil distribution plate, responsible for the direct conversion of hydraulic energy into rotational energy.

For cycloidal motors: This consists of the stator, rotor, and needle bearings, generating rotation through continuous changes in the hydraulic chamber.

Output Shaft

Transmits the rotational power to the planetary reducer.

The bearing support design must withstand long-term high axial and radial loads.

Planetary Gear Sets

Typically comprised of one or two planetary gear sets, they reduce speed and amplify torque through meshing.

The gears are carburized and hardened to ensure wear and fatigue resistance.

Brake System

Multi-plate wet brakes utilize hydraulic release and spring braking to ensure the track locks immediately upon oil loss or equipment shutdown.

Seals & Bearings

High-temperature, high-pressure, wear-resistant seals prevent hydraulic oil leakage and prevent the ingress of mud and sand.

High-load roller bearings ensure low-friction operation even under heavy loads.

The design quality of these components directly determines the lifespan and maintenance costs of the track motor.

4. Common Types of Hydraulic Track Motors

Track motors are generally divided into two categories:

Efficient and precise control

Suitable for heavy-duty, high-pressure applications

Commonly found in large excavators and mining equipment

Track motors

Compact and cost-effective

Suitable for small crawler machines

Low speed but high starting torque

5. Practical Operation of Hydraulic Track Motors

Let’s use a 20-ton excavator as an example:

The operator commands movement—the joystick movement signals the main control valve to send oil to the left or right crawler motor.

High-pressure oil enters the engine—pressures in heavy equipment can reach up to 350 bar.

The piston or rotor turns the output shaft—the hydraulic force is converted into mechanical torque.

The planetary gears multiply the torque—reduction ratios of 30:1 or higher can generate tremendous pulling force.

The sprockets rotate the track chain links—the entire machine moves forward, backward, or turns.

6. Why Hydraulic Track Motors Are Essential:

Hydraulic track motors provide:

Smooth, precise control—ideal for positioning heavy loads. High torque at low speeds—essential for climbing grades or pushing materials.

Reversibility—the track can change direction instantly.

Durability—designed for continuous operation under extreme conditions.

Without these, the raw power of a hydraulic pump is useless for actual machine movement.

7. Business Purchasing Considerations

For original equipment manufacturers (OEMs), fleet managers, or repair shops, selecting the right crawler hydraulic motor requires considering the following factors:

Pressure and torque ratings—must meet the machine’s requirements.

Mounting dimensions—ensure compatibility with the final drive housing.

Gear reduction ratio—affects travel speed and pulling force.

Brand and parts availability—reduce downtime during maintenance.

Warranty and after-sales support—ensure long-term reliability.

Buyer’s Tip: Always verify the motor’s flow capacity to prevent overheating and premature wear.

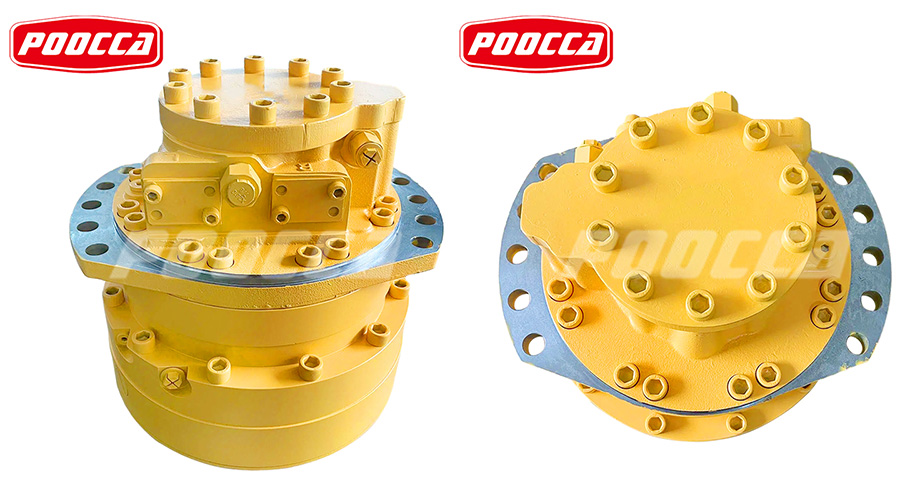

9. Poocca Hydraulic Manufacturing – Your Track Motor Partner

Being a trusted hydraulic solutions supplier, Poocca Hydraulic Manufacturing manufactures an entire line of hydraulic track motors for excavators, crawler drills, and other tracked equipment.

Model range to select from – Meets brands such as CAT, Komatsu, Hitachi, and Doosan.

Specification adjustable – Customize torque, speed, and mounting configurations.

Stringently quality tested – Pressure, leak, and performance test every motor.

Fast delivery – Extensive inventory available for immediate shipment.

Technical support – Assistance from selection to installation.

For purchasing managers, partnering with Poocca means ensuring reliable, high-performance track motors that keep your machines running and your projects on schedule.

10. The Future of Hydraulic Track Motors

With electric and hybrid drive trains gaining popularity, hydraulic track motors are bound to have more advanced control electronics to offer smooth integration with electric pumps and computer-based machine control systems.

Despite all this, the principles involved in converting hydraulic energy into reliable track movement remain the same, proving the base of heavy-duty mobility is still hydraulic technology.

Final Words

From small crawler skid-steer loaders to massive mining crawler excavators, hydraulic track motors power the equipment constructing roads, buildings, and infrastructure. Operators, engineers, and purchasing departments need to know how they work.

Whether you’re replacing a failed final drive or purchasing a part for new equipment, remember that the quality of your motor is the performance of your track.

Poocca Hydraulics stands prepared to supply you with long-lasting, high-efficiency motors that will yield long-term value. Give us a call today to go over your requirements and keep your machine in motion.

Post time: Aug-09-2025