In the world of hydraulic systems, understanding the intricacies of the various components is critical to efficiency and functionality. One of the key elements is the variable displacement piston pump. This innovative device is at the heart of numerous industrial applications, helping to deliver hydraulic energy with precision and control. A closer look at how it works reveals the fascinating mechanisms that underpin its reliability and versatility.

The core working principle of a variable displacement piston pump is to convert mechanical energy into hydraulic energy. The process begins with the rotation of a drive shaft, usually powered by an electric motor or internal combustion engine. As the shaft turns, it activates a series of interconnected parts within the pump assembly.

The core component of the piston pump is the piston. These pistons are housed in a cylindrical chamber and create reciprocating motion when acted upon by a rotating shaft. This reciprocating motion creates alternating suction and discharge cycles within the pump, which are essential for the suction and subsequent pressurized output of hydraulic fluid.

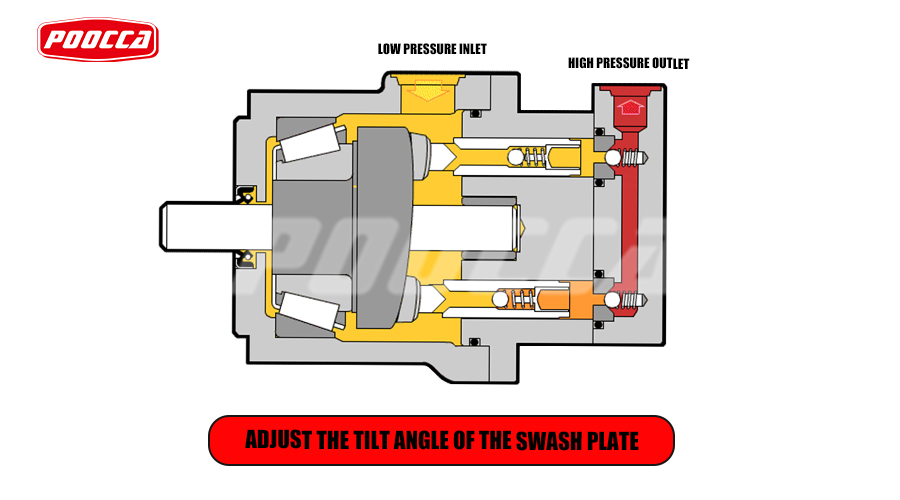

Crucially, a variable displacement piston pump differs from a fixed displacement pump in its ability to regulate the amount of fluid displaced per cycle. This adjustability is achieved through complex control mechanisms integrated into the pump design. By changing the stroke length or angle of the swash plate (the tilted component that regulates piston movement), the operator can adjust the pump’s output to meet the requirements of the hydraulic system.

The versatility provided by variable displacement capability is a boon to a range of applications. This flexibility proves invaluable in situations where changes in load or operating conditions require dynamic fluid flow. Whether it’s industrial machinery, construction equipment or aerospace systems, the ability to fine-tune hydraulic output can improve equipment performance, efficiency and service life.

The precise control provided by a variable displacement piston pump helps save energy. By delivering only the necessary amount of hydraulic oil at any given moment, waste is minimized and energy consumption optimized. This not only reduces operating costs but is also consistent with sustainability goals, making variable displacement pumps the first choice for modern hydraulic systems.

Variable displacement piston pumps go beyond mere functionality. Its sturdy construction and reliable performance ensure a long service life and minimal downtime, vital factors in industries where productivity is critical. Regular maintenance and monitoring are essential to maintain optimal performance, but with proper care, these pumps can work reliably for a long time.

Innovations in materials and manufacturing processes continue to improve the design and performance of variable displacement piston pumps. From advanced alloys that enhance durability to precision machining techniques that increase efficiency, ongoing research and development efforts promise to deliver even greater reliability and efficiency in the future.

The working principle of a variable displacement piston pump epitomizes the combination of mechanical engineering and fluid dynamics. Through careful design and precision engineering, these pumps embody versatility, efficiency and reliability – indispensable qualities in a variety of hydraulic applications. As the industry evolves and the need for complex hydraulic systems grows, the role of variable displacement piston pumps remains vital, driving progress and powering the machinery of modern civilization.

Post time: Apr-09-2024