Hydraulic gear pumps are the backbone of countless hydraulic systems in industrial and mobile applications. Among these, the HGP Series Gear Pumps are a class of external, fixed‑displacement gear pumps known for their simplicity, cost‑effectiveness, and reliability in delivering consistent flow and pressure. These attributes make them a popular choice for both new designs and replacement projects — whether in construction equipment, factory automation, agricultural machinery, or material handling systems.

What Is the HGP Series Gear Pump?

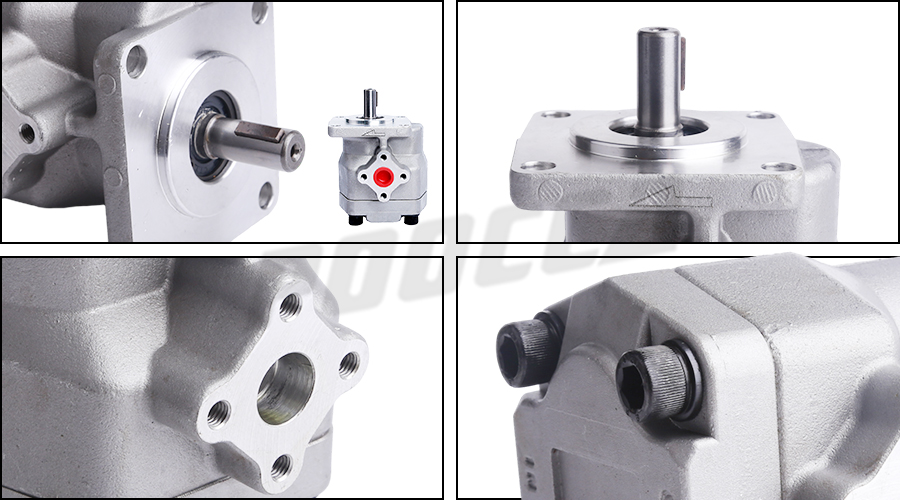

The HGP Series Gear Pump is a type of external, fixed‑displacement hydraulic gear pump designed for medium‑to‑high pressure hydraulic systems. It uses a classic external gear structure — where two meshing gears create suction at the inlet and discharge pressure at the outlet — to deliver a continuous, steady flow of hydraulic fluid. This simplicity of mechanical design makes HGP pumps robust, reliable, and relatively easy to maintain compared to more complex pump types.

How It Works

At its core, a gear pump consists of two precision machined gears enclosed in a rigid housing:

-

As the drive gear rotates, it pulls fluid into the pump chamber through the inlet.

-

The fluid is carried between the gear teeth and the housing to the outlet.

-

Because the gears mesh and unmesh in a precise, controlled manner, the pump produces a consistent flow rate per revolution — this is why gear pumps are often described as fixed‑displacement.

Core Design Features

HGP Series pumps distinguish themselves in several ways:

-

External Gear Structure: Simple, mature design with excellent reliability.

-

High Efficiency: Precision machining and tight gear clearances minimize internal leakage, giving high volumetric and mechanical efficiency.

-

Durable Construction: High‑strength aluminum alloy housing and anti‑wear bearings support continuous operation under load without rapid wear.

-

Compact and Lightweight: Aluminum body reduces overall weight while maintaining structural strength.

-

Low Noise Operation: Careful gear and housing design reduces vibration and noise compared with low‑quality gear pumps.

Pressure & Performance

HGP Series pumps are typically rated for maximum service pressures up to around 250 bar (≈3500 psi) — suitable for many industrial and mobile hydraulics applications.

HGP Product Family & Technical Specifications

Typical HGP Model Categories

Single Gear Pumps

These are the most common HGP variants, providing fixed displacement and consistent flow:

-

HGP‑1A Series Gear Pump — Budget‑friendly standard series with compact size suitable for low‑to‑mid flow applications.

-

HGP‑1A‑F3R High‑Pressure Gear Pump — Single HGP‑1A unit with modest displac

-

HGP‑2A Gear Pump — Mid‑range single pump with broader displacement options and more capacity for industrial use.

-

HGP‑3A Series Gear Pump and **** — Larger displacement options for higher flow demands.HGP‑3AF14R Gear Pump — Larger displacement options for higher flow demands.

These single pumps generally support rotations from low to mid RPM and are most commonly used where a single stable hydraulic circuit

Key Technical Specifications

HGP Series pumps share a set of standardized performance characteristics across models:

Maximum P

-

Most HGP Series pumps are rated for maximum service pressures up to ~250 bar (3500 psi) — suitable for a wide range of hydraulic applications.

-

Pump housings are typically high‑strength aluminum alloy, providing a good balance of stiffness, durability and lower weight.

Displacement Range

-

Single HGP units

-

Tandem double sections combine two displacement values for dual‑output configurations.

Speed & Rotation

-

Typical rated speeds range from ~1800 to 4500 rpm depending on model size and application

-

Pumps are offered with both clockwise and counter‑clockwise rotation options, allowing flexibility in installation.

Mounting & Flange Standards

HGP series support a variety of mounting interfaces:

-

SAE 2‑bolt and DIN 4‑bolt flanges

-

Foot mounting for larger models

-

Multiple shaft types (straight, spline, tapered, depending on version)

Fluid Compatibility

-

Designed for hydraulic fluids with typical viscosities such as ISO VG32 or VG46.

-

Operating temperature range and fluid filtration requirements vary by model and supplier.

Displacement & Pressure Summary

Below is a simplified range overview based on common HGP series families:

| Series | Displacement Range (approx.) | Max Pressure | Notes |

|---|---|---|---|

| HGP‑1A | ~0.5 – ~8 cc/rev | ~250 bar | Compact, entry to mid flow capacity |

| HGP‑2A | ~2 – ~?? cc/rev | ~250 bar | Broader mid flow range |

| HGP‑3A | ~2 – ~35 cc/rev | ~250 bar | Larger single pump, higher flow |

| HGP‑33A Tandem | Combined sections (e.g., 6+6 cc/rev) | ~250 bar | Two sections for dual circuits |

| HGP‑11A Duplex | Small dual units, e.g., 0.5+0.5 cc/rev | ~250 bar | Mini tandem option |

Key Features & Performance Benefits (Optimized)

The HGP Series Gear Pumps stand out by combining robust construction, efficient performance, and practical adaptability — traits valued across industrial and mobile hydraulics.

High Pressure Capability and Solid Construction

HGP pumps are typically designed for service pressures up to about 250 bar (≈3500 psi), making them suitable for a broad spectrum of applications from construction machinery to industrial power units. The high‑strength aluminum alloy housing provides structural rigidity while keeping weight down.

Efficient and Reliable Flow Delivery

With precision‑machined gear sets and an engineered internal clearance compensation mechanism, HGP pumps deliver high volumetric and mechanical efficiency. This translates to more consistent fluid delivery per revolution and lower internal leakage over time.

Durability and Long Service Life

Composite bearings and high‑performance seals help HGP pumps withstand extended operation under pressure without premature wear. These design choices reduce downtime and maintenance costs in heavy‑duty systems.

Compact, Lightweight with Low Noise

The compact footprint and light weight of HGP pumps make them easy to install in space‑constrained applications. Precision gear processing and optimized internal design also contribute to lower noise and smoother operation compared with many lower‑quality gear pumps.

Typical Application Scenarios

HGP Series Gear Pumps are widely used across diverse industrial and mobile hydraulic systems due to their balanced performance, ruggedness, and cost-effectiveness. Their ability to deliver consistent flow under medium-to-high pressure makes them a go-to solution in many engineering environments.

Mobile & Construction Machinery

These pumps are frequently installed in hydraulics for construction and utility vehicles, where they supply hydraulic power to actuators, cylinders, steering systems, and other motion control elements. Examples include loaders, excavators, forklifts, and lift equipment — which benefit from reliable flow and pressure without excessive complexity.

-

SINOCMP HGP-33A-F6-6R Hydraulic Tandem Double Gear Pump — ideal for applications requiring dual-circuit outputs such as separate steering and implement circuits in mobile machinery.

-

Gear Pump HGP-1A Hydraulic Gear Pump Small Oil Pump HGP-1A-F — compact single pump for smaller mobile hydraulics.

Industrial Hydraulic Systems

In manufacturing and automation facilities, HGP series pumps are used to power hydraulic power units that drive presses, machine tools and material handling equipment. Their durability and low-noise operation suit continuous industrial environments.

-

HGP Gear Pump Pressure Hydraulic Oil Pump Rotary Quantitativ — versatile choice for medium-pressure industrial circuits.

-

Hydraulic Gear Pump HGP-3A-F15R HGP-3A-F6R HGP-3A-F8R HGP-3A — larger displacement option for higher flow industrial requirements.

Agricultural, Forestry & Material Handling

HGP pumps are also suitable for agricultural machinery (tractors, harvesters), forestry equipment, and handling gear such as lifts and conveyors. These sectors often demand rugged, easy-to-service pumps that provide consistent performance in challenging environments.

Systems with Multiple Outputs

Tandem and duplex configurations enable a single pump to supply two hydraulic circuits independently, which can simplify system design and reduce the number of separate pumps needed.

-

High Pressure Duplex Gear Pump Hgp-11a-f4-4r/f2-2r/f3-3r Hyd — example of a dual-section pump for multi-circuit hydraulics.

-

Tandem Double Gear Hydraulic Pumps Hgp-33a-f6/6r Double Gear — cost-effective tandem option for moderate flow systems.

HGP vs Other Gear Pumps (Comparison & Misconceptions)

External Gear (HGP) vs Internal Gear Pumps

External gear pumps like the HGP series — where two external gears mesh in a housing to move fluid — are widely used in medium-to-high pressure hydraulics. They are valued for simplicity, robustness, and consistent volumetric output. In contrast, internal gear pumps use an internal/external gear pair with a crescent partition and typically handle a broader range of fluid viscosities with less pulsation.

Comparison Highlights:

| Feature | HGP (External Gear) | Internal Gear |

|---|---|---|

| Pressure Capability | Up to ~250 bar (≈3500 psi) — good for industrial & mobile use | Lower typical max pressure; designed more for smooth flow |

| Flow Consistency | Good and predictable | Very smooth with low pulsation |

| Fluid Viscosity Range | Best for typical hydraulic oils | Broader – handles high viscosity better |

| Noise | Moderate | Usually quieter |

| Cost | Lower | Often higher |

| Complexity & Service | Simple, easy to maintain | Slightly more complex |

When to choose HGP:

-

You need medium-to-high pressure with reliable delivery.

-

Your working fluid is standard hydraulic oil.

-

Cost and maintenance simplicity matter.

When internal gear pumps may suit better:

-

System requires low pulsation, quieter operation, or varied viscosity handling (e.g., specialized industrial processes).

HGP vs Premium Brand External Gear Pumps

Manufacturers like Bosch Rexroth and Parker produce gear pumps with extensive modular options, certifications, and performance testing. For instance, some premium external gear pumps offer pressure ratings tailored to heavy industrial environments, interchangeable cartridges, and built-in relief or load sensing features.

Typical Trade-Offs:

| Dimension | HGP Series | Premium Brand Pumps |

|---|---|---|

| Price | More affordable | Higher cost |

| Configuration Options | Good but standard | Extensive modular options |

| Performance Curves & Testing | Reliable | Often deeper documented test data |

| Certification/Compliance | Depends on supplier | Often includes specific industrial standards |

Best choice scenarios:

-

HGP pumps are excellent when basic performance, cost control, and reliability are your priorities.

-

Premium gear pumps are justified when specific certifications, extended warranties, or complex integrations are required.

Common Misconceptions About Gear Pumps

Misconception 1: “All gear pumps perform essentially the same.”

Not true. Design details like gear profile, tolerances, materials and internal clearances significantly affect efficiency, noise, lifetime, and pressure handling. HGP series pumps benefit from precision machined components that deliver good volumetric efficiency and service life without premium pricing.

Misconception 2: “Higher pressure rating always means better performance.”

A higher maximum pressure rating is only valuable if your system actually demands it. Specifying excessive pressure capability adds unnecessary cost and may reduce efficiency in typical operating ranges.

Misconception 3: “External gear pumps always have high pulsation.”

While external gear pumps have inherent pulsation due to gear chambers engaging and disengaging, modern HGP designs use precision machining and optimized tooth profiles to minimize pulsation and noise within acceptable ranges for most hydraulic systems.

Practical Selection Guidance

To choose the right gear pump type, ask yourself:

-

Pressure needs: What maximum and continuous pressures will your system experience? (HGP ~250 bar is robust for most industrial cases).

-

Fluid type: Are you pumping typical hydraulic oil or something with unusual viscosity?

-

Noise requirements: Is low acoustic output critical?

-

System complexity: Do you need multiple flow paths (tandem types like SINOCMP HGP-33A-F6-6R Hydraulic Tandem Double Gear Pump or High Pressure Duplex Gear Pump Hgp-11a-f4-4r/f2-2r/f3-3r Hyd) from one unit?

Frequently Asked Questions (FAQs)

1. What are the most common performance issues with gear pumps, and how can they be prevented?

Leakage and loss of flow:

Internal leakage — due to worn clearances between gears and housing — can reduce volumetric efficiency and output pressure. Maintaining tight tolerances during manufacture and inspecting for wear regularly helps maintain performance. Choosing the correct fluid viscosity also reduces internal slip losses.

2. Why is fluid viscosity important for HGP gear pump performance?

Hydraulic gear pumps like the HGP Series are optimized for standard hydraulic oil viscosities (e.g., ISO VG32–VG46). If the fluid is too thin, internal leakage increases and reduces efficiency. If it’s too thick, it can struggle to fill the gear cavities, leading to reduced flow or cavitation. Operating within the correct viscosity range — and monitoring fluid temperature — helps preserve flow, efficiency and pump life.

3. Can HGP pumps operate in reverse flow or bi-directionally?

Yes — external gear pumps are inherently reversible: if the shaft rotates in the opposite direction, they will pump fluid in reverse with similar performance, as long as the suction and discharge ports are correctly managed in system design.

4. What maintenance practices extend the life of a gear pump?

Strong maintenance practices include:

-

Regularly inspecting and replacing seals and bearings before they fail.

-

Replacing filters and keeping the fluid clean to prevent abrasive wear.

-

Ensuring proper lubrication and avoiding extended dry running, which can quickly damage gear surfaces.

-

Monitoring operating temperatures and correcting overheating or cavitation issues promptly.

Proper preventive maintenance minimizes breakdowns and ensures consistent performance.

5. What causes reduced pump pressure or early failure?

Common root causes include:

-

Contaminated fluid accelerating internal wear.

-

Worn seal or bearings, increasing clearances and leakage.

-

Overloading or high operating temperatures that exceed design limits.

-

Blocked suction strainers or hoses, reducing suction performance and increasing cavitation risk.

Addressing these design and maintenance points can reduce unplanned failures.

Conclusion

Throughout this article, we’ve taken a deep dive into the HGP Series Gear Pumps — from what they are and how they work, to real-world applications, technical advantages, comparisons with other gear pump types, and practical selection guidance. The HGP Series stands out as a robust, cost-effective and reliable external gear pump solution suitable for a wide range of applications including mobile machinery, industrial hydraulic power units, agricultural systems and multi-circuit installations.

It’s important to recognize that while HGP pumps excel in many core applications, the right choice always depends on your precise system needs — such as required flow, pressure, fluid type, operating environment and maintenance expectations. Matching these criteria with the right HGP model will ensure optimal performance and long service life.

At Poocca, we pride ourselves on deep industry expertise and a full portfolio of high-quality hydraulic components designed to meet diverse engineering challenges. Whether you’re specifying a new hydraulic system or upgrading existing equipment, we offer:

-

Hydraulic Pumps — including gear pumps like NSH, SGP and HGP Series

-

Hydraulic Valves — control, directional, pressure and flow solutions

-

Hydraulic Motors — reliable torque and power elements for mobile and industrial systems

-

Complete Custom Solutions — tailored help with product selection, system integration and technical support

Our team is ready to help you select the right pump and system configuration for your specific application — from initial calculation and modeling to installation advice and after-sales support.

Ready to take the next step? Contact Poocca today for expert consultation and to explore the best hydraulic pump solutions for your needs.

Let’s power your success together.

Post time: Dec-24-2025