Among the many options available, two types of positive-displacement rotary pumps most often come under consideration: the gear pump and the lobe pump. While they share the purpose of moving liquids in demanding environments, their internal design and functional characteristics differ significantly. This article provides a professional and authoritative comparison between gear pumps and lobe pumps — examining how each works, where each excels, and how you can strategically select the optimal pump type for your system and fluid specificities.

Pump Type Introduction

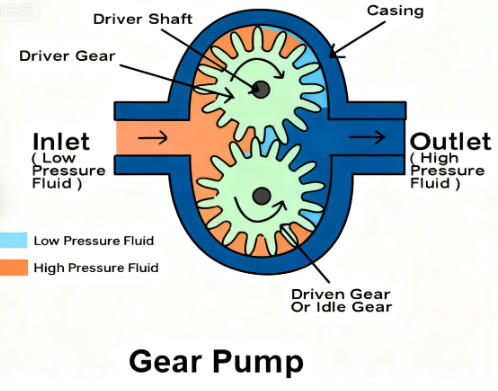

Gear Pump

A gear pump is a form of positive‐displacement pump that transports fluid by the meshing of gears.As the gears rotate, they separate on the suction side, creating a void or low-pressure region into which the fluid is drawn. The fluid is then trapped between the gear teeth and the pump casing, carried around to the discharge side, and finally squeezed out as the gear teeth re‐mesh, thereby forcing the fluid into the outlet.

There are two primary design variants:

-

External gear pump, which uses two identical gears meshing directly, each on its own shaft.

-

Internal gear pump, which features one gear within another (an idler inside a larger driven rotor) and often employs a crescent seal to isolate the inlet and outlet flow paths.

In industrial practice, gear pumps are widely used across hydraulic power applications, lubrication systems, and high-viscosity fluid transfer because of their ability to develop consistent, metered flows and relatively high pressures.

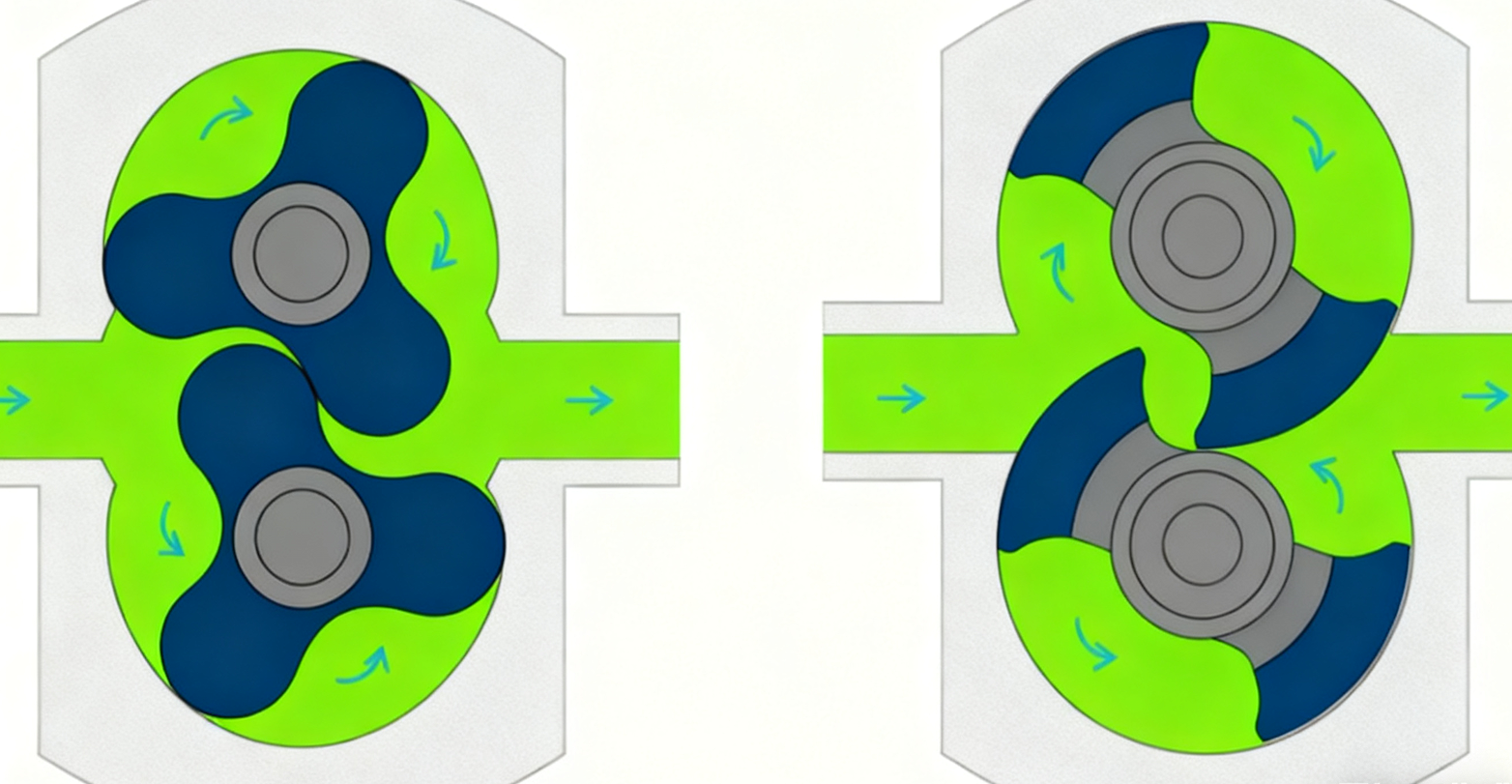

Lobe Pump

A lobe pump (also called a rotary lobe pump) is another type of positive-displacement rotary pump.It shares some operational similarities with gear pumps in the sense that fluid is entrained in cavities created by rotating elements and transported from the inlet to the outlet. However, its mechanical construction and operating characteristics differ significantly.

In a lobe pump, two or more lobed rotors (rather than simple gears) rotate in a close-fitting casing. Critically, the lobes do not make contact with each other (they are synchronised by external timing gears) — this non‐contacting design means the fluid is carried gently in large cavities between the lobes and the casing.

The working cycle is as follows: the lobes rotate such that when they move away from each other on the inlet side, a cavity expands and fluid is drawn into it; then the lobes carry the fluid around the casing, and finally the lobes mesh or come close on the discharge side, reducing the cavity volume and forcing the fluid out of the outlet.

Lobe pumps are especially favoured in industries where sanitary conditions, low shear handling, or solids‐bearing fluids are involved (for example food, beverage, pharmaceuticals) because the non‐contacting lobes and large pumping cavities reduce damage to the fluid and handle particles better.

Structural & Mechanical Differences

Here is a comparative summary of structural and mechanical aspects:

| Structural/Mechanical Feature | Gear Pump | Lobe Pump |

|---|---|---|

| Contact between moving parts | Gears mesh or rotate in close clearance → contact or near-contact wear potential. | Lobes do not touch; synchronized externally → lower internal wear. |

| Clearances & cavities | Very tight clearances for accurate displacement and minimal back-leakage. | Larger cavities relative to gear pump; allows larger solids, viscous fluid. |

| Pressure capability | Generally higher, due to rigid gear mesh and casing support. | Typically lower maximum pressure in general, though depends on design. |

| Shear / fluid handling | Higher shear due to meshing gear movement and tight clearances. | Lower shear because lobes carry fluid gently in large pockets. |

| Maintenance / wear | More wear potential on gears, bearings; may require more frequent servicing. | Less internal wear; easier maintenance in many designs; better suited for tough fluids. |

| Sanitary / special-fluid suitability | Can be adapted for sanitary use, but often less inherent in design. | Designed often for sanitary/hygienic use, viscous/particulate fluids. |

Performance Parameters

In selecting the right pump type, the structural differences we discussed translate directly into performance characteristics that determine suitability for a given application. Below are key parameters to compare between gear pumps and lobe pumps, along with the practical implications for industrial and hydraulic systems.

Summary Table of Performance Parameters

| Parameter | Gear Pump | Lobe Pump |

|---|---|---|

| Preferred viscosity range | Low-to-medium; can handle moderate but efficiency drops at very high viscosities | Medium-to-high; very good at viscous or particulate-loaded fluids |

| Max pressure capability | Higher capability, suitable for high-pressure systems | Generally lower pressure capability, optimized for moderate pressures |

| Flow control / metering | Excellent, consistent fixed displacement | Good, but slightly more variability under high differential pressure |

| Shear impact on fluid | Higher shear – less suited for delicate fluids | Lower shear – suited for shear-sensitive fluids |

| Wear & maintenance | More wear potential due to gear contact and tight clearances | Less internal wear; potentially longer service life in right conditions |

| Initial cost and complexity | Generally lower cost, simpler design | Higher cost, more complex design (especially sanitary models) |

Application Comparisons

In real-world settings, the choice between gear pumps and lobe pumps comes down to matching the pump type to the fluid characteristics, operating environment and system requirements. Below are comparative application insights tailored to industrial hydraulics and process fluid transfer.

Gear Pump Applications

-

Ideal for hydraulic systems, lubrication circuits, oil transfer, and other scenarios where the fluid is a relatively clean, low-to-medium viscosity oil or hydraulic fluid. For example, in mobile equipment or power units needing high pressure and consistent flow, gear pumps are a strong fit.

-

Because gear pumps offer good pressure capability and fixed displacement behaviour, they serve well in metering, dosing, or systems where flow rate needs to be proportional to speed and stable under load.

-

That said, gear pumps are less suitable when the fluid contains large solid particles, is extremely viscous (thick pastes/slurries), or requires ultra-gentle handling (e.g., shear sensitive). In such cases, wear, leakage and damage risk increase.

Lobe Pump Applications

-

Lobe pumps become the preferred choice when the fluid is viscous, contains solids, requires low shear (to preserve product integrity), or operates in sanitary environments (food, beverage, pharma). For instance, syrups, sludges, slurries, paste-like materials or hygienic transfer lines easily suit lobe pumps.

-

Lobe pumps are designed with larger cavities, non-contacting rotors and clean-in-place (CIP)/sterilise-in-place (SIP) capability (in sanitary variants), making them suited to sensitive processing applications.

-

On the flip side, if the system demands very high pressure differentials, or the fluid is simple hydraulic oil with no special handling requirement, then a lobe pump may be over-designed and less efficient compared to a gear pump.

Application Guide & Selection Advice

In real-world industrial systems, selecting between a gear pump and a lobe pump demands mapping performance parameters to application requirements. Below are key guidance points to apply in your pump procurement and system-design decisions:

Match by Fluid & System Conditions

-

Fluid viscosity & composition: If the pumped medium is a standard hydraulic oil or low-to-medium viscosity fluid (with minimal particulates), a gear pump is typically the most efficient choice. In contrast, if the fluid is highly viscous, contains solids, or is shear-sensitive, a lobe pump is usually more appropriate.

-

Pressure and flow demands: Systems that demand high pressures and precise metering (such as hydraulic power units or mobile equipment hydraulics) favour gear pumps, reflecting their superior pressure capability and flow consistency.Meanwhile, if pressure requirements are moderate and fluid handling is more critical (e.g., viscous slurries or sanitary fluids), a lobe pump may be the better match.

-

Product integrity and maintenance environment: For applications in hygiene-sensitive industries (food, beverage, pharma) or where minimal shear and easy cleaning are priorities, the lobe pump’s design advantages are significant.In contrast, gear pumps shine where robustness, compact design and lower initial cost matter more than sanitary features.

-

Total lifecycle cost: While gear pumps often come with lower upfront cost, the long-term cost (maintenance, downtime, wear) must be weighed if the operating conditions are harsh (high abrasives, solids) which may favour a lobe pump’s longer service life in those contexts.

Decision Matrix for Quick Reference

| Condition | Likely Best Choice | Reason |

|---|---|---|

| Hydraulic oil, high system pressure (>200 bar), minimal solids | Gear Pump | High pressure capability, metered flow, proven in hydraulics. |

| Viscous fluid (>10,000 cP), contains particles, sanitary requirement | Lobe Pump | Large flow cavities, low shear, easy cleaning, handles solids well. |

| Fluid thin, moderate pressure, price sensitive | Gear Pump | Simpler design, lower cost, sufficient performance for many tasks. |

| Need gentle handling of emulsions/slurries, lower pressure range | Lobe Pump | Protects fluid integrity, suited for sensitive media. |

Why Choose Poocca?

At Poocca, we specialise in OEM/ODM manufacturing of high-precision gear pumps, with a strong track record of supplying hydraulic gear pumps, gear pump assemblies and customised solutions in the mobile-equipment and industrial hydraulic market. Our offerings include:

-

A wide model range of gear pumps designed for high pressure, compact size, and high-precision metering control.

-

Flexible customization to match your fluid type, system pressure, displacement, port orientation and mounting.

-

Full after-sales support including maintenance guidance, spare parts, and service interval recommendations tailored to your duty cycle.

-

Expert guidance on when a gear pump is the right fit — and honest advice when alternative pump technologies (like lobe pumps) may better suit your application — positioning ourselves as your trusted solutions partner, not just a component supplier.

If you’re evaluating pump options for your next system build or retrofit, please contact us today with your fluid details and system specs. We’ll work with you to determine whether a gear pump from our Poocca line is the optimal choice — or coordinate with you on the right pump type for your unique needs.

Frequently Asked Questions

Q1: Can a gear pump handle very high viscosity fluids?

A: Gear pumps are best suited to low-to-medium viscosity fluids. Their tight clearances and meshing gears limit their efficiency with thick or high-viscosity media.

Q2: Is a lobe pump suitable for high-pressure hydraulic systems?

A: Generally no — lobe pumps offer lower maximum discharge pressures compared to gear pumps, making them less ideal for heavy hydraulic systems requiring high pressure.

Q3: What kind of fluids are lobe pumps particularly good for?

A: Lobe pumps excel in handling high-viscosity fluids, slurries or solids-laden media, and shear-sensitive or sanitary applications thanks to their non-contacting rotor design and large pumping cavities.

Q4: Why might maintenance be more frequent with gear pumps?

A: Because gear pumps involve meshing gears and very small clearances, wear and internal leakage can increase over time — particularly when the fluid has particles or is abrasive — which may lead to more frequent maintenance.

Q5: How should I choose between a gear pump and a lobe pump?

A: Consider your fluid’s viscosity, solids content, shear sensitivity, required system pressure and flow rate, and cleaning or sanitary needs. Match the pump type to these parameters. If you’re unsure, consult with a pump specialist.

Post time: Nov-12-2025