1. The role of the hydraulic pump

The hydraulic pump is the heart of the hydraulic system, referred to as the hydraulic pump. In a hydraulic system, there must be one or more pumps.

The pump is the power element in the hydraulic transmission system. It is driven by the prime mover (motor or engine) to obtain mechanical energy from the output power, and converts it into the pressure energy of the fluid to provide pressure oil for the system, and then in the place where work is required, The fluid is converted into mechanical output by the actuator (hydraulic cylinder or motor).

2. Classification and selection of hydraulic pumps

Generally speaking, the pump is either a positive displacement pump or a non-positive displacement pump, and the pump in the hydraulic system belongs to the positive displacement pump. The positive displacement pump refers to the pump that absorbs and discharges oil by relying on the change of the sealing volume. The existence of the sealing volume and the performance change of the sealing volume are the working principles of all positive displacement pumps. (The common water pump is a non-displacement pump).

1. Classification of pumps:

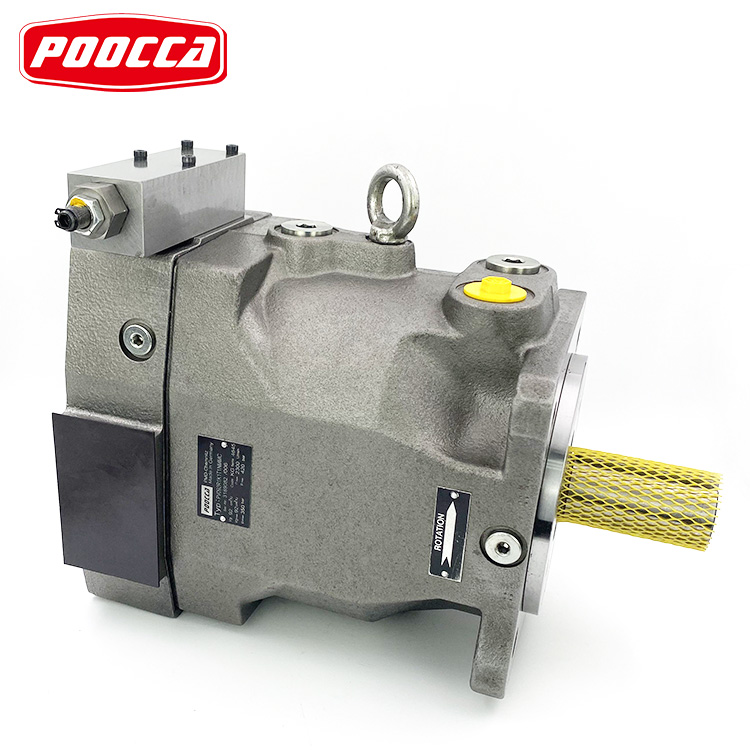

According to the structure, it can be divided into: gear pump, vane pump, plunger pump and screw pump.

According to the flow can be divided into: variable pump and quantitative pump! The output flow can be adjusted according to the needs called variable pump, the flow can not be adjusted called quantitative pump.

2. Selection of pump

(1) Select the pump according to the working pressure:

Plunger pump 31.5mpa;

Vane pump 6.3mpa; can reach 31.5mpa after high pressure

Gear pump 2.5 ohm mpa; can reach 25mpa after high pressure

(2) Select the pump according to whether the variable is required; if the variable is required, the single-purpose vane pump, axial piston pump and radial piston pump can be selected.

3. Select the pump according to the environment; the gear pump has the best anti-pollution ability.

4. Select pumps according to noise; low-noise pumps include internal gear pump, double-acting vane pump and screw pump.

5. Select the pump according to the efficiency; the total power of the axial piston pump is the highest, and the pump with the same structure with a large displacement has the highest efficiency. The pump with the same displacement has the highest total efficiency of the axial piston pump under rated operation.

Therefore, when choosing a hydraulic pump, there is no best, only the most suitable.

Post time: Oct-13-2022