In the world of fluid handling and hydraulic systems, choosing the right pump is one of the most critical decisions you’ll make. Whether you’re designing a new system or upgrading an existing one, understanding the differences between centrifugal pumps and gear pumps isn’t just academic — it directly impacts your system’s performance, reliability, cost, and long‑term value.

Basic Principles & Definitions

In order to make an informed decision between centrifugal pumps and gear pumps, you first need to understand how each type works at a fundamental level. These differences in working principles directly affect performance, suitability for different fluids, efficiency, and ultimately your system design and operating costs.

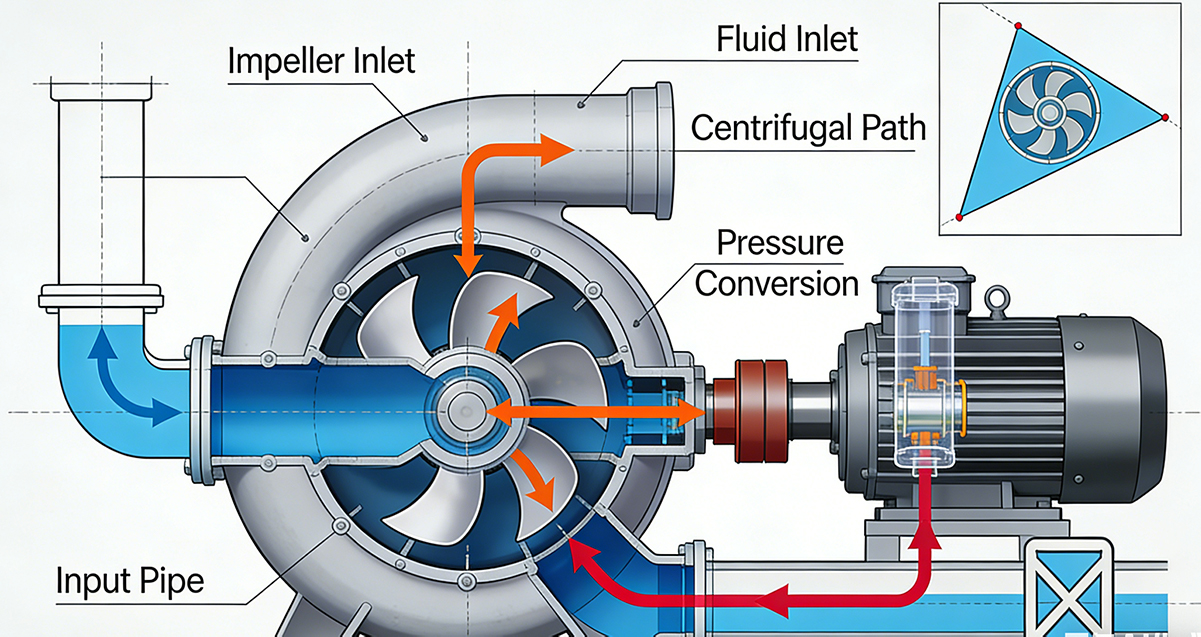

What Is a Centrifugal Pump?

A centrifugal pump is a rotodynamic pump that converts mechanical energy into fluid movement by using a high‑speed rotating impeller. As the impeller spins, it throws fluid outward by centrifugal force, increasing its velocity. That kinetic energy is then converted into pressure energy in the pump casing before the fluid exits to the discharge line.

Key aspects of centrifugal pumps:

-

Working principle: Impeller accelerates fluid outward, generating flow and pressure through dynamic action.

-

Energy conversion: Mechanical energy → kinetic energy → pressure energy.

-

Flow behavior: Output is strongly influenced by system back‑pressure — as pressure rises, flow typically falls.

Because complexity is limited to the impeller and housing, centrifugal pumps are widely chosen for simple, high‑flow, low‑to‑moderate pressure fluid transfer.

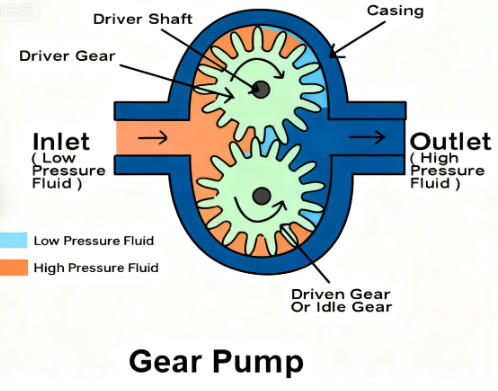

What Is a Gear Pump?

A gear pump is a type of positive displacement (PD) pump. Instead of relying on centrifugal force, it mechanically traps fixed volumes of fluid between interlocking gears and forces that volume from the inlet to the outlet with each rotation.

Key features of gear pumps:

-

Operating principle: Meshing gears create sealed chambers that carry fluid consistently from inlet to outlet.

-

Flow behavior: Nearly constant flow per revolution and largely independent of system pressure changes (within design limits).

-

Types: External gear pumps (two gears meshing externally) and internal gear pumps (one gear inside another).

This mechanical displacement approach gives gear pumps excellent performance with viscous fluids and high pressures, which is why they’re preferred in hydraulic circuits, lubrication systems, fuel delivery, and precise metering applications.

Core Technical Comparison

| Aspect | Centrifugal Pump | Gear Pump |

|---|---|---|

| Pump Type | Dynamic / Rotodynamic — uses centrifugal force via impeller to accelerate fluid. | Positive Displacement — gear meshing mechanically traps and pushes fluid. |

| Operating Principle | Converts velocity into pressure — flow depends on rotational speed and system pressure. | Moves fixed volume per gear revolution — flow proportional to speed and nearly independent of pressure. |

| Flow vs Pressure Behavior | Variable flow: declines significantly as discharge pressure increases. | Constant flow: flow remains relatively steady even with pressure changes. |

| Viscosity Handling | Best with low‑viscosity fluids (water, thin chemicals); efficiency drops with higher viscosity. | Handles high‑viscosity fluids (oils, resins) well with minimal performance loss. |

| Pressure Capability | Moderate maximum pressure; efficiency decreases at higher pressure. | Stronger pressure performance; delivers higher pressures effectively. |

| Flow Characteristics | Smooth flow, but dependent on system characteristics. | Steady flow with slight pulsation from gear action. |

| Priming & Cavitation | Typically requires priming; more susceptible to cavitation at low inlet pressure. | Often self‑priming; less prone to cavitation due to positive displacement action. |

| Efficiency Trends | High efficiency with low‑viscosity fluids and near design point. | Efficiency can be good at design speed and pressure but generally lower with thin fluids. |

| Maintenance & Complexity | Simpler design with fewer moving parts — generally easier maintenance. | More mechanical components — can require more frequent inspection and seal care. |

| Typical Applications | High flow, low‑to‑medium pressure fluids (water treatment, irrigation, HVAC). | High pressure, low‑to‑medium flow, viscous fluids, precise metering (hydraulics, lubrication, dosing). |

| Cost Considerations | Generally lower initial cost and simpler to manufacture. | Usually higher cost due to precision gear machining. |

Applications & Use Cases

Typical Applications for Centrifugal Pumps

Centrifugal pumps are most effective in high‑flow, low‑to‑moderate pressure scenarios with low‑viscosity fluids.

Common centrifugal pump use cases include:

-

Water supply and distribution — municipal systems, boosting stations, and potable water transfer.

-

Irrigation and agriculture — moving large volumes of water over land or between reservoirs.

-

HVAC and circulation systems — chilled water, condenser water, and building systems often rely on centrifugal designs.

-

General industrial fluid transfer — low‑viscosity chemicals, light lubricants, and bulk fluid movement.

Why centrifugal works here:

Their design supports high throughput with relatively low energy loss when fluid viscosity is low and pressure demands are not extreme. Maintenance tends to be simpler due to fewer moving parts.

Typical Applications for Gear Pumps

Gear pumps shine in lower flow, higher pressure, and precisely controlled delivery applications — especially where viscous fluids are involved.

Common gear pump use cases include:

-

Hydraulic power systems — feeding actuators and control circuits with consistent, predictable flow.

-

Lubrication systems — circulating oil to bearings, turbines, compressors, and other rotating equipment.

-

Fuel and oil transfer — diesel fuel delivery, heavy oils, and gear oils.

-

Chemical and food processing — metering syrups, fats, resins, and other viscous liquids where precise volumetric control matters.

Why gear pumps are preferred here:

Their positive displacement action delivers a nearly constant flow per revolution, which makes them excellent for dosing, metering, and systems where changes in back pressure don’t significantly alter flow.

Real Selection Scenarios

Here are example scenarios to help you link performance needs to the right pump choice:

Scenario A — Large Chemical Plant Transfer:

You need to move thousands of liters per hour of a low‑viscosity process chemical between stages. A centrifugal pump is a strong fit due to its ability to move high volumes efficiently.

Scenario B — Heavy Oil Injection in Machining:

A lubrication system must deliver consistent, controlled flow of high‑viscosity oil to spindles under varying pressures. A gear pump delivers predictable flow regardless of pressure swings.

Scenario C — Hydraulic Actuation:

A mobile hydraulic actuator requires precise volumetric delivery at high pressure to control movement. A gear pump provides stable flow and strong pressure capability.

Common Misconceptions

When people talk about centrifugal pumps versus gear pumps, there are several widespread myths and misunderstandings that can lead to wrong choices, under‑performing systems, or unnecessary costs. Below are key misconceptions — and the real technical facts you need to know:

“Centrifugal Pumps Can Pump Air”

Myth: Centrifugal pumps can handle and pump air effectively.

Truth: Centrifugal pumps rely on fluid being present at the impeller to generate pressure. While they can entrain small amounts of gas, they cannot effectively pump air without priming because they cannot develop enough suction to lift gas against atmospheric pressure.

“Centrifugal Pumps Save Power if Started With Discharge Valve Closed”

Myth: Starting a centrifugal pump with its discharge valve closed saves energy.

Truth: While it reduces torque at startup, keeping the discharge valve closed introduces high radial thrust on the impeller, which can damage the shaft or mechanical seal.

“Gear Pumps Are the Only Pumps That Create Pressure”

Myth: Gear pumps are unique among pumps in their ability to generate pressure differential.

Truth: While gear pumps are good at producing and maintaining pressure due to positive displacement, other PD pumps (piston, vane, diaphragm, etc.) also generate significant pressure differentials. The strength of gear pumps is steady flow under pressure, not exclusivity in pressure creation.

“Gear Pumps Can’t Be Used With Thin Liquids”

Myth: Positive displacement gear pumps are unsuitable for thin low‑viscosity fluids.

Truth: Many PD pumps, including gear pumps, can handle thin liquids (e.g., water, solvents, light fuels) if properly selected and built with compatible materials. The key is pump material and clearances, not an absolute viscosity cutoff.

“Gear Pump Flow Is Fixed and Cannot Be Controlled”

Myth: Because gear pumps have fixed displacement, their flow cannot be adjusted.

Truth: You can control flow by changing drive speed with a variable frequency drive (VFD) or using downstream control valves — the pump still provides constant displacement, but system control can vary delivered flow.

“Centrifugal and Gear Pump Maintenance and Wear Are the Same”

Myth: All pumps wear similarly and require the same maintenance.

Truth:

-

Centrifugal pumps generally have fewer moving parts and fewer close‑tolerance components, so they often need simpler maintenance.

-

Gear pumps have many interlocking components and tight clearances, so wear and internal leakage (“slip”) can affect flow over time — especially with abrasive or contaminated fluids.

“Pump Selection Isn’t Sensitive to Fluid Viscosity”

Myth: You can choose any centrifugal pump regardless of fluid viscosity.

Truth: Centrifugal pump performance drops significantly with increasing viscosity — reducing flow, head, and efficiency. Gear pumps maintain performance much better with higher viscosity fluids.

Pump Selection Flow

Here’s a straightforward step‑by‑step process to help you choose between a centrifugal pump and a gear pump before you request quotes or technical support:

-

Determine Flow & Pressure Needs — identify required flow rate and system pressure/head. These are the first filters in pump type selection.

-

Check Fluid Properties — note viscosity, density, temperature, and chemistry of the medium; high viscosity points toward gear pumps, low viscosity toward centrifugal.

-

Match Pump Type to Conditions — choose centrifugal for high flow with low‑to‑moderate pressure and low‑viscosity fluids; choose gear pump for steady flow under pressure and viscous fluids.

-

Verify Installation Constraints — review suction conditions (e.g., NPSH for centrifugal), space, orientation, and priming needs.

-

Use Pump Curves — find a pump model whose flow vs head curve intersects your system requirements near the best efficiency point.

-

Confirm Materials & Seals — ensure wetted parts are compatible with the fluid’s temperature and chemistry.

-

Evaluate Total Cost — compare lifecycle costs including energy, maintenance, and spare parts, not just initial price.

-

Request Quotes & Support — send your requirements to suppliers for performance confirmation, quotation, and technical guidance before final purchase.

Conclusion & Poocca Recommendation

Choosing between a centrifugal pump and a gear pump comes down to matching your system’s functional needs with the strengths of each pump type:

-

Centrifugal pumps are ideal for high‑flow, low‑to‑moderate pressure applications and are generally simpler, more cost‑effective, and efficient with low‑viscosity fluids like water or light chemicals. They are widely used in water circulation, HVAC, irrigation, and general industrial fluid transfer.

-

Gear pumps excel in low‑to‑moderate flow, higher pressure applications where consistent volumetric flow and the ability to handle viscous fluids (oils, lubricants, resins) matter. They are often found in hydraulic systems, lubrication circuits, fuel oil handling, and precise dosing setups.

Before you finalize your pump choice, always clarify your flow, pressure, and fluid parameters, then verify with manufacturer performance curves to ensure the selected model meets your system demands.

At Poocca, we bring 20 + years of industry expertise in hydraulic and industrial pump systems, backed by practical field experience and detailed application knowledge. Our approach helps you:

-

Match the right pump type (centrifugal vs gear) to your system’s real needs.

-

Optimize total cost of ownership, not just upfront price.

-

Access tailored technical support and reliable after‑sales service.

Whether you need a centrifugal pump for high‑volume transfer or a gear pump for precise, high‑pressure fluid delivery, Poocca can assist with professional selection, performance verification, and custom quotations tailored to your application.

Contact us today to discuss your specific project requirements and get an optimized pump solution that delivers performance, reliability, and value you can trust.

Post time: Dec-25-2025