In hydraulic systems and fluid power applications, gear pumps are among the most widely used types of positive-displacement pumps. A gear pump works by having two (or more) gears mesh and unmesh to create suction on the inlet side and force fluid through the outlet side.

When the pump housing is made of cast iron, the result is a cast iron gear pump — a variant prized for its robustness, dimensional stability, and suitability for demanding industrial conditions.

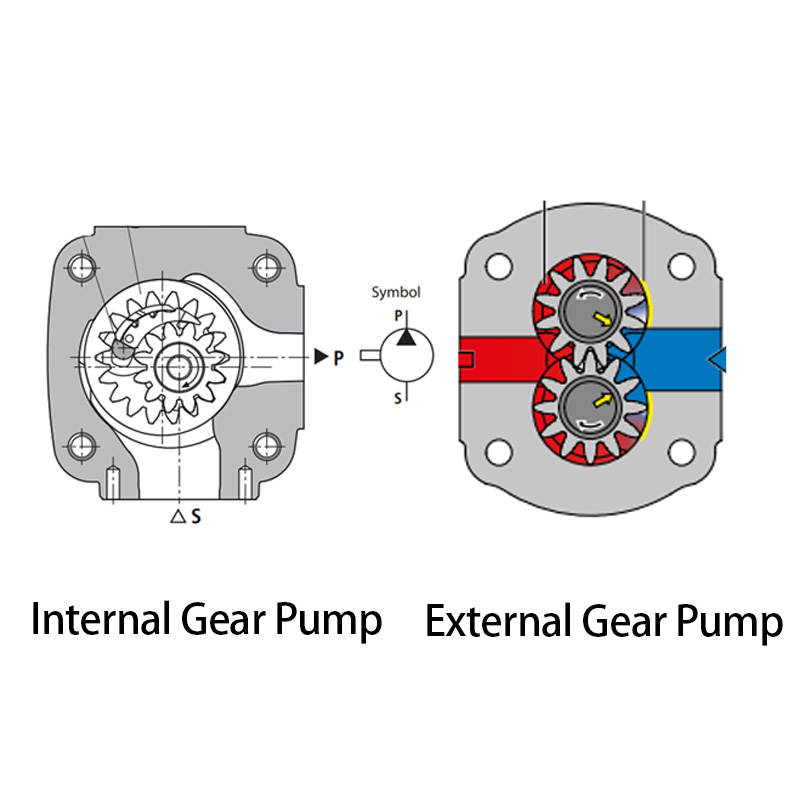

Working Principle of Gear Pumps

A gear pump is a type of positive-displacement rotary pump: as gears rotate, they create expanding and contracting cavities that draw in fluid and then discharge it.

External Gear Pump

-

External gear pumps have two identical intermeshing gears inside a casing. One gear is driven; the other (idler) is driven by its mesh.

-

On the inlet side, as the gears rotate apart, expanding cavities generate suction and draw fluid in.

-

The fluid is carried in the spaces between teeth, around the outside of the gears, toward the outlet.

-

On the discharge side, as the teeth mesh again, the trapped volume shrinks and forces fluid out under pressure.

Pros / cons in short:

-

Good for higher pressures and moderate viscosities.

-

Sensitive to leakage (“slip”) if clearances grow or fluid is low viscosity.

Internal Gear Pump

-

Internal gear pumps use an outer rotor gear and an inner idler gear that meshes inside it, often with a crescent partition to separate inlet and discharge zones.

-

During rotation, inlet side opens up, drawing fluid into the gear cavities; the fluid then travels around the casing along the crescent; at discharge, the shrinking volume forces fluid out.

-

Internal gear pumps often provide smoother flow, better suction handling, and can be more tolerant of viscous fluids.

-

Their pressure limits tend to be lower compared to external gear pumps.

Leakage, Slip & Efficiency

-

No pump is perfect: leakage (slip) occurs through the small clearances between gear teeth and casing, reducing effective output.

-

Volumetric efficiency equals the actual flow divided by the ideal flow (if no leakage). Efficiency declines as leakage increases.

-

As clearances wear or fluid viscosity is low, slip increases. Also, friction, side loads, and mechanical losses reduce overall efficiency further.

Key Formulae (Brief)

-

Flow rate (Q) ≈ displacement per revolution × rotational speed

-

Power = flow rate × pressure differential

-

Overall efficiency = volumetric efficiency × mechanical efficiency

Why Choose Cast Iron for Gear Pumps

Key Advantages

-

Strength & Structural Integrity

Cast iron provides excellent capacity to withstand internal pressures and mechanical stresses without deforming. This ensures that critical clearances remain stable under load. -

Vibration Damping & Noise Reduction

Due to its dense, granular microstructure, cast iron naturally absorbs vibration. This leads to quieter operation and reduces fatigue stress on internal components. -

Thermal Stability

Cast iron expands less under heat compared to lighter alloys (like aluminum), which helps maintain dimensional tolerances and reduce thermal distortion in pump bodies. -

Wear Resistance / Self-lubrication

Many cast iron grades include graphite in the matrix, which helps reduce friction and improve wear resistance of sliding surfaces. -

Cost & Machinability

Cast iron is relatively economical to produce (especially in complex shapes) and can be machined to tight tolerances needed for gear pump parts. -

Repair & Maintenance

Because cast iron is widely used and understood in industry, spare parts, repair techniques, and refurbishment capabilities are common and well supported.

Trade-offs & Limitations

-

Weight

Cast iron is significantly heavier than aluminum or composite materials. In applications where weight is a constraint (e.g. mobile machinery), this can be a drawback. -

Corrosion Susceptibility

Cast iron is vulnerable to rust and corrosion, especially in water, humid, or chemically aggressive environments. It often requires protective coatings or liners. -

Brittleness / Impact Sensitivity

While excellent under compressive loads, cast iron is more brittle than ductile metals—it tolerates less impact or shock without cracking. -

Not Ideal for Highly Corrosive Fluids

In pumping aggressive chemicals (strong acids, chlorides, etc.), cast iron may degrade too quickly. In those cases, stainless steel, coated alloys or non-metallic materials may be better.

Design & Construction Features

In this section, we examine the key structural elements of a cast iron gear pump: how they are built, what design choices matter, and how they influence performance and reliability.

Pump Housing / Body

-

The pump body is usually cast from grey cast iron or ductile (spheroidal graphite) iron, offering good machinability, strength, and damping.

-

The casing often splits along a median plane (i.e. two halves) or has removable front / rear covers for access.

-

Precision machining is applied to internal surfaces (gear bores, bearing seats, port faces) to maintain tight tolerances and minimize leakage.

-

In more advanced designs, the housing may include pressure-balanced covers or thrust plates to reduce internal stresses and improve efficiency under high pressure. (e.g. Danfoss Rugid pumps use dual pressure-balanced thrust plates)

-

The body must also accommodate ports (suction and discharge), mounting flanges or feet, and alignment for the drive shaft(s).

Gears (Rotor / Idler) & Gear Geometry

-

Gears are usually made from hardened steel (often through surface hardening or nitriding) to resist wear.

-

The gear profile (spur, helical, herringbone) affects noise, load distribution, and smoothness.

-

Clearances between gear teeth and between outer diameter and casing are critical: too tight → risk of rubbing or seizure; too loose → excessive leakage (slip).

-

Some designs adopt balancing pistons/blocks or side sealing elements to relieve side thrust and equalize pressures. For example, Bucher’s AP212HP series uses cast iron covers and internal balancing blocks.

Covers, Side Plates & Seals

-

Front/rear covers (or end plates) seal the gear chamber and house bearings, seals, and possibly balancing features.

-

Seals (mechanical seals, lip seals, or O-rings) prevent external leakage along the shaft and interfaces.

-

Side plates (on left/right faces of the gear set) ensure minimal leakage in the axial direction and maintain alignment.

-

In high-pressure pumps, the covers and plates may include pressure-balancing features to minimize side loading on bearings.

Shafts, Bearings & Thrust Elements

-

The drive shaft must be designed to handle torque, radial loads, and axial (thrust) loads without undue deflection.

-

Bearings (bronze bushings, ball bearings, roller bearings) are located in the housing or covers. In cast iron pumps, bronze-backed bearings are sometimes supported in the front flange. (noted in Danfoss Rugid series)

-

Thrust surfaces or plates relieve axial forces arising from pressure differentials. Balanced thrust designs help prolong life and reduce bearing loads.

-

Proper alignment and mounting are essential: shaft misalignment transmits forces that accelerate wear of bearings and seals.

Sealing, Leakage Control & Clearances

-

Leakage control is fundamental: small clearances, labyrinths, or sealing lands help to reduce slip.

-

Designers balance between too tight (risk of interference, seizure, high friction) and too loose (loss of volumetric efficiency).

-

Some pumps employ pressure-balancing or compensating grooves to stabilize leakage under varying pressures.

-

Surface finishes on sealing surfaces are critical (low roughness, proper flatness) to limit leakage paths.

Applications & Use Cases

| Application Sector | Typical Fluid / Scenario | Why Use Cast Iron Gear Pump | Key Challenges / Considerations |

|---|---|---|---|

| Industrial Hydraulics & Machinery | Hydraulic oil for presses, machine tools, factory systems | High structural strength, stability, long service life | Fluid cleanliness critical; wear increases internal leakage over time |

| Mobile / Construction / Agricultural Equipment | Circulation of hydraulic fluids in excavators, tractors, loaders | Good vibration damping; durable under shock and cyclic loads | Weight is a drawback; need to accommodate temperature and seal stability |

| Lubrication / Oil Transfer / Circulation | Engine lube, gearbox oil, system oil recirculation | Positive-displacement assures steady flow even under backpressure | High backpressure increases internal slip; filtration is essential |

| Chemical / Process Plants | Pumps for resins, polymers, additives, solvents | Can be adapted with coatings or linings; handles relatively viscous fluids | For highly corrosive fluids cast iron must be protected or replaced by alloys; solids/abrasives must be filtered |

| Coatings, Paints, Inks | High-viscosity paints, ink, pigments, adhesives | Gear pumps (especially internal types) provide smooth flow, less pulsation | Solids/particulates present risk of abrasion; cleaning and maintenance are concerns |

| Food / Oils / Syrups | Vegetable oils, syrups, fats, food additives | If equipped with food-grade coatings or linings, possible in milder conditions | Cast iron often not ideal for hygienic standards; corrosion and cleaning must be managed |

Commentary & Highlights

-

Gear pumps are widely used for pumping high-viscosity fluids such as oils, resins, paints and also in metering / blending operations because their flow is proportional to rotational speed, largely independent of pressure (within design limits).

-

In industrial applications, cast iron gear pumps find use across fuels & lubricants, resins & polymers, solvents, paints & inks, food products, etc.

-

External gear pumps tend to support higher pressures, making them suitable for hydraulic or power applications. Internal gear (crescent) types are often preferred when suction performance or smoother flow is more critical (e.g. in coating or food sectors).

-

The challenges across applications often converge on:

• Managing abrasive particles or solids — these accelerate wear and degrade performance

• Providing adequate filtration & fluid cleanliness

• Ensuring compatibility with fluid corrosiveness, temperature, and viscosity

• Designing for maintenance / cleanability, especially in sensitive industries (e.g. food, coatings)

cast iron gear pumps remain a staple in hydraulic and fluid power systems thanks to their structural rigidity, wear resistance, and ability to deliver stable, metered flow under heavy load. Though they are not without trade-offs (such as weight, corrosion susceptibility, and sensitivity to fluid cleanliness), proper design, material selection, maintenance, and system integration can maximize their life and performance.

For readers who are exploring concrete hydraulic component sources, Poocca Hydraulics is worth noting. Poocca, based in Shenzhen, China, is a one-stop hydraulic OEM/ODM company specializing in gear pumps, piston pumps, vane pumps, motors, valves, and related accessories.

They maintain modern machining and testing capabilities and offer a broad model range, which may be helpful if you’re considering procurement or customization.

Post time: Sep-26-2025