When it comes to reliable, high-efficiency hydraulic pumps for industrial and mobile applications, Casappa Gear Pumps stand out as one of the most versatile and widely used solutions in the global market. Casappa S.p.A., an Italian manufacturer with decades of experience, has built a strong reputation for producing robust external gear pumps that balance performance, durability, and integration flexibility.

Casappa gear pumps are designed to serve a broad range of hydraulic systems — from construction and agricultural machinery to forklifts, truck PTOs, and industrial presses. Their broad series lineup, from lightweight aluminum models to heavy-duty cast iron units, allows designers and engineers to select the right pump to meet specific flow, pressure, and mounting requirements.

What Is a Gear Pump

A gear pump is a type of positive displacement pump that moves fluid by trapping fixed volumes between the teeth of rotating gears and transporting it from the inlet to the outlet. Because the amount of fluid moved per revolution is fixed, the flow output is directly proportional to the rotational speed of the pump. This makes gear pumps highly predictable and suitable for many hydraulic applications.

There are two main categories:

-

External gear pumps — the most common type in hydraulic systems.

-

Internal gear pumps — use a different gearing arrangement for specific applications.

Casappa Gear Pump Product Families & Specs

Casappa Gear Pump Families at a Glance

Here’s a structured breakdown of the major Casappa gear pump types and how they differ in construction, performance, and suitable applications:

| Series | Body Material | Displacement Range | Max Pressure | Max Speed | Application Focus |

|---|---|---|---|---|---|

| POLARIS (PL) | Aluminum | ~1.07 – 91.10 cc/rev | 300 bar | 4000 rpm | General industrial / mobile hydraulics |

| WHISPER (WS) | Aluminum (low noise) | ~1.12 – 96.85 cc/rev | 300 bar | 4000 rpm | Low-noise systems, versatile |

| POLARIS PH | Cast iron | ~8.26 – 33.03 cc/rev | 300 bar | 3500 rpm | Higher durability than aluminum, heavy use |

| XHP | Cast iron (helical gear) | ~8.06 – 28.01 cc/rev | 300 bar | 4000 rpm | High reliability / temperature tolerance |

| KAPPA (K) | Cast iron | ~4.95 – 180.73 cc/rev | 330 bar | 4000 rpm | Heavy-duty, high flow |

| FORMULA (FP) | Cast iron | ~8.26 – 150.79 cc/rev | ~325–330 bar | 3000 rpm | Truck PTOs, low-speed torque systems |

| MAGNUM (HD) | Cast iron | ~17.28 – 125.63 cc/rev | 320 bar | 3000 rpm | High-duty industrial use |

Series Highlights & Technical Notes

POLARIS (PL) – Versatile Baseline Pump

-

Material: Extruded aluminum alloy housing.

-

Performance: Up to 300 bar peak pressure, speeds up to 4000 rpm.

-

Advantages: Lightweight, broad range of displacements and mounting options. Suitable for many standard hydraulic circuits.

-

Built-In Options: Anti-cavitation, pressure relief, priority valves, etc.

WHISPER (WS) – Low Noise Optimization

-

Key Feature: Proprietary low noise design for quieter operation.

-

Performance: Similar displacement and pressure ranges to POLARIS but optimized for noise-sensitive systems.

-

Use Cases: Indoor machinery, mobile equipment where noise budget matters.

POLARIS PH & XHP – Cast Iron Strength

-

POLARIS PH: Cast iron evolution of the PL series with better durability and noise characteristics. Ideal when aluminum pumps approach their limits (e.g., heavy loaders, forklifts).

-

XHP: Helical gear design improves smoothness, high-temperature performance, and reliability.

KAPPA (K) – Heavy-Duty Workhorse

-

Material: Two-piece cast iron.

-

Strengths: Wide displacement range (from compact sizes to high-flow units), higher pressure capability (~330 bar), and long working life.

-

Best For: Large mobile equipment, industrial hydraulics with demanding flow and pressure.

FORMULA (FP) – PTO & Low-Speed Torque Focused

-

Design Focus: Optimized for truck and tractor PTO drive applications, strong torque at low speed around 300 rpm minimum.

-

Advantages: Good for systems where low speed/high torque performance matters.

-

Mounting & Seals: Configured for direct PTO mounting with robust shaft seals.

MAGNUM (HD) – Industrial Versatility

-

Highlights: Reliable under extreme conditions, multiple port/shaft options, and modular integration.

-

Mounting Flexibility: Standard and common inlet configurations for complex system layouts.

Key Technical Features Explained

Pressure & Flow Capabilities

Casappa gear pumps are designed for high operational pressures and predictable flow outputs:

-

Max peak pressure: Up to ~300 bar for aluminum and many cast-iron units; up to ~330 bar for heavy-duty cast iron models like KAPPA.

-

Peak pressure range examples:

-

Standard PL/PH/XHP series: ~300 bar (~4350 psi)

-

KAPPA (K) series: ~330 bar (~4785 psi)

-

FORMULA (FP): ~325 bar (~4713 psi)

-

-

Displacement vs flow: Flow rises proportionally with pump speed at a given displacement — e.g., a 20 cc/rev pump at 1500 rpm delivers ~30 L/min. This linear relation makes sizing straightforward.

These ratings ensure Casappa gear pumps can handle medium to heavy hydraulic work — from lifting cylinders to steering circuits — with reliable pressure performance.

Material Choices & Structural Design

Two main body materials drive the performance envelope:

-

Aluminum (e.g., POLARIS / WHISPER series): Light weight with excellent volumetric efficiency and corrosion resistance. Good for mobile and industrial systems where weight matters.

-

Cast iron (e.g., PH, XHP, KAPPA, FORMULA, MAGNUM): Higher structural strength, lower noise, better wear resistance under heavy load and heat, and often longer service life.

Additional design highlights include:

-

Outboard bearings integrated in many models for handling higher radial loads and extending life.

-

Precision gear machining improves volumetric efficiency and reduces internal leakage, enabling better performance at high pressure.

-

Series like XHP use helical gear designs for smoother flow and reduced noise.

Built-In Valves & Functional Options

One reason Casappa gear pumps outperform many generic alternatives is the range of integrated valve options that simplify system design and improve performance:

-

Anti-cavitation valves protect the pump from damaging suction cavitation.

-

Maximum pressure relief valves safeguard circuits from overpressure.

-

Priority and load-sensing priority valves enable smart flow control in multi-actuator systems.

-

By-pass and proportional relief valves provide additional control flexibility.

These built-in options reduce the need for external control valves, cutting system complexity and installation cost.

Mounting, Ports & Shaft Interfaces

Beyond raw pressure and flow numbers, mounting and interface standards are critical for real-world integration:

-

Casappa supports multiple mounting standards including SAE and DIN flanges.

-

Shaft options like splined, parallel key, and tapered designs improve compatibility with different drive systems.

-

Multiple port configurations allow engineers to optimize system plumbing and reduce hose runs.

Proper shaft/port matching drastically reduces installation headaches and avoids costly redesigns.

Noise, Temperature & Efficiency Considerations

-

Most Casappa series operate at voltage-friendly noise levels due to refined gear and housing design.

-

Temperature tolerance of cast iron models (like PH and XHP) tends to be better than aluminum under prolonged heavy use.

-

High volumetric efficiency (often ~90 %+ under ideal conditions) ensures most of the theoretical flow is actually delivered, translating into better overall system efficiency.

How to Choose the Right Casappa Gear Pump

-

Define flow requirements by determining the hydraulic fluid volume your system must deliver per minute.

-

Match operating pressure by selecting a pump rated at or above your system’s maximum pressure with a safety margin.

-

Consider fluid viscosity and temperature to ensure the pump’s materials and clearances are compatible with your working media.

-

Check fluid chemistry and abrasives to avoid excess wear or corrosion from incompatible materials or particles.

-

Evaluate mounting and mechanical compatibility including flange type, shaft interface, and installation space.

-

Account for suction and discharge conditions to prevent cavitation and performance losses.

-

Balance efficiency and lifecycle value by favoring higher quality designs that reduce long-term energy and maintenance costs.

-

Consult performance curves or expert support to verify that your chosen model operates well within recommended limits.

Common Misconceptions & Clarifications

Misconception 1: “Gear pumps can handle any fluid type without issues.”

Reality: Gear pumps rely on tight internal clearances, so very low-viscosity fluids can cause internal leakage and loss of effective flow, while inappropriate fluids may also fail to lubricate moving parts properly. This affects volumetric efficiency and can accelerate wear.

Misconception 2: “Higher fluid viscosity always improves performance.”

Reality: While moderate viscosity helps reduce internal slippage, excessively viscous fluids increase friction, demand higher torque, and can cause startup difficulties or heat buildup — all of which negatively impact pump life and efficiency.

Misconception 3: “Once installed, gear pumps don’t need maintenance.”

Reality: Gear pumps require regular maintenance, including fluid cleanliness, filter checks, and inspections of seals and bearings — especially when operating in harsh environments — to sustain performance and avoid premature failures.

Misconception 4: “Gear pumps can run dry or with intermittent flow.”

Reality: Gear pumps depend on pumped fluid for lubrication and cooling; running dry or with insufficient fluid supply can lead to overheating, accelerated wear, and even irreversible damage.

Misconception 5: “Flow and pressure adjust within the pump itself.”

Reality: Most gear pumps are fixed-displacement — they deliver a set volume per revolution. Flow changes with speed, but pressure and flow adjustments require external controls (e.g., relief valves, variable-speed drives), not the pump alone.

Casappa vs Other Brands

Here’s a data-driven comparison of Casappa gear pumps against major competitors in the hydraulic gear pump market — focusing on performance positioning, design priorities, and real purchase considerations. This section helps you objectively evaluate where Casappa stands relative to other well-known brands from both technical and commercial perspectives.

Brand Positioning Overview

| Brand | Core Strengths | Typical Use Cases | Relative Positioning |

|---|---|---|---|

| Casappa | Compact designs, modular options, good cost-to-performance | General industrial & mobile systems | Mid-range global competitor with strong adaptability |

| Bosch Rexroth | Precision manufacturing, high reliability, wide adoption in automation | High-end industrial machinery | Premium performance and durability |

| Parker Hannifin | Broad product line, robust design, high speed/pressure capability | Industrial and mobile hydraulics | Performance-focused premium option |

| Marzocchi | Low noise, efficient flow, smooth operation | Mobile machinery and vibration-sensitive applications | Medium-high quality with noise-optimized designs |

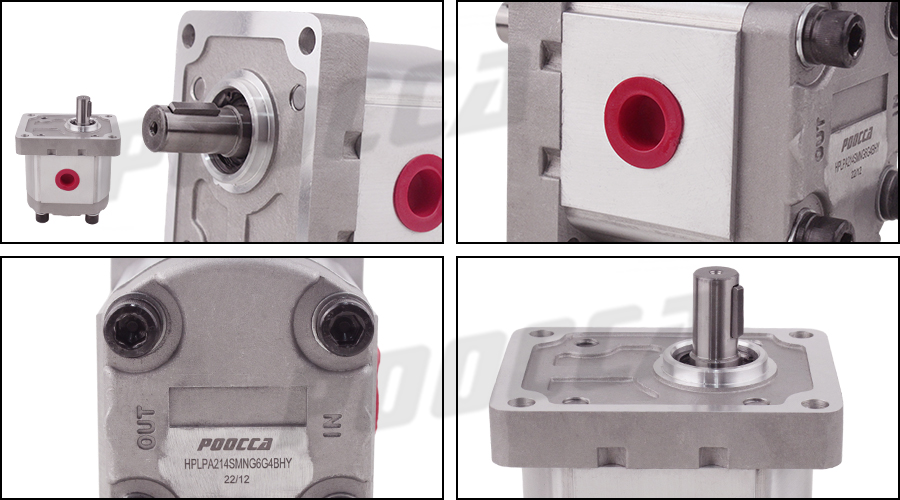

| OEM/Regional Suppliers (e.g., Poocca) | Customizable options, cost-effective solutions | OEM projects, tailored applications | Value-oriented choice with flexibility |

FAQs

Q: What is the pressure rating for Casappa gear pumps?

Casappa gear pumps typically handle peak pressures up to ~300 bar (4350 psi) for standard series and up to ~330 bar (4785 psi) for heavy-duty models like KAPPA, making them suitable for most industrial and mobile hydraulic applications.

Q: Can gear pumps handle all hydraulic fluids?

No — gear pumps have tight internal clearances and are sensitive to fluid viscosity and contamination. Very low-viscosity or abrasive fluids can cause internal leakage and accelerated wear, so always choose compatible hydraulic oil and proper filtration.

Q: Do gear pumps automatically adjust flow and pressure?

Most gear pumps (including Casappa) are fixed-displacement, meaning they deliver a set volume per revolution. Flow changes with speed, but pressure and precise control require external valves or control systems; the pump itself cannot vary displacement.

Q: What are common selection mistakes with gear pumps?

Common mistakes include selecting based on price alone, ignoring operating conditions (pressure, fluid properties, temperature), overlooking internal leakage and efficiency data, and failing to check maintenance/support availability — all leading to inefficiency or early failure.

Call to Action

Now that you’ve gained a deep, expert-level understanding of Casappa gear pumps — from technical fundamentals to series comparisons, built-in options, and real-world selection guidance — it’s time to turn insight into results for your project.

At Poocca, we specialize in hydraulic pump solutions that match your exact system requirements, whether you’re designing a new machine or upgrading an existing hydraulic circuit. We provide:

-

Custom model recommendations based on your flow, pressure, and speed specs.

-

Compatibility checks for mounting, shaft interfaces, and valve integration.

-

Detailed performance analysis with manufacturer data and installation advice.

-

Flexible sourcing options including Casappa gear pumps and tailored OEM configurations.

Get the right pump, not just a pump.

Share your application details—flow rate, operating pressure, fluid type, speed range, and mounting constraints—and our hydraulic experts at Poocca will help you identify the best Casappa gear pump solution that fits your system and budget.

Contact Poocca Hydraulic Experts Today:

Provide your specs and we’ll respond with a tailored recommendation.

Ask about lead times, pricing, and technical support.

Post time: Jan-30-2026