In the demanding world of compact construction machinery, hydraulics serve as the invisible muscle behind every lift, tilt, steer and drive motion. For machines from the Bobcat brand (skid-steers, compact loaders, track loaders, telehandlers) the choice and condition of the hydraulic pump can make or break machine performance. Among the most vital components in the hydraulic system is the gear pump. In this article we focus on the “Bobcat gear pump” — what it is, why it matters, and how choosing the right one can dramatically impact uptime, productivity and cost-of-ownership.

What Is a Gear Pump?

In the context of hydraulic systems, a gear pump is a type of positive-displacement pump that moves fluid by mechanically trapping a fixed volume and forcing it from the inlet to the outlet.

Definition & Working Principle

-

A gear pump uses two (or more) meshing gears rotating inside a closely fitted housing. As the gears unmesh at the inlet side, a low-pressure region is created which draws fluid in. As the gears rotate, fluid is carried around the outer periphery of the gears, and then as the gears mesh again at the outlet side, the fluid is displaced and forced out under pressure.

-

Because of this meshing action, gear pumps provide flow that is proportional to shaft speed (i.e., each revolution displaces a fixed volume). This makes them predictable and suitable for many hydraulic applications.

-

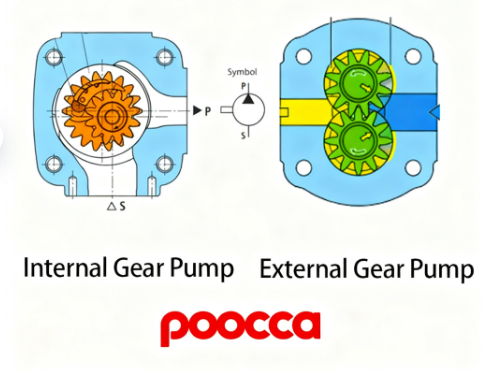

They come in two main designs:

-

External gear pump: Two identical external gears (driver + idler) mesh together.

-

Internal gear pump (also called eccentric gear): One larger internal gear and one smaller external gear housed within it, often with a crescent-shaped partition.

-

Application of Bobcat gear pump

Typical Hydraulic Applications in Bobcat Machines

Bobcat machines — including skid-steers, compact track loaders, telehandlers — rely heavily on hydraulic power for a variety of functions: driving the tracks or wheels, operating lift arms, tilting buckets, powering auxiliary attachments such as augers, breakers, and grapple arms. According to the Bobcat parts catalogue, hydraulic pumps generate fluid pressure that is delivered via the system’s hoses and valves to hydraulic motors and cylinders.

In many of these machines, a gear pump form factor is used because it satisfies the flow/pressure demands and spatial constraints of these applications.

Advantages of Gear Pumps for Bobcat Use-Cases

-

Compact and rugged design: Gear pumps offer relatively compact dimensions and fewer moving parts compared to some other pump types. This makes them well-suited for machines where space is limited and the environment is demanding (e.g., construction, dirt, shocks).

-

Predictable, fixed displacement flow: As documented, gear pumps are positive displacement devices — they deliver a consistent volume of fluid per revolution.In Bobcat machines where predictable flow is required (e.g., when actuating attachments), this is beneficial.

-

Robustness in harsh mobile environments: Because gear pump internals are typically more straightforward, they handle moderate pressures and hydraulic oils well, which aligns with the needs of Bobcat’s compact machine hydraulics.

-

Cost-effectiveness for standard duty: For many Bobcat applications (auxiliary circuits, lift arm drives, etc.), the premium cost of more complex variable displacement pumps may not be justified — making gear pumps a sensible choice.

Specific Features for Bobcat Gear Pump Application

Beyond the general benefits, Bobcat (and OEMs alike) will expect the gear pump to meet certain specific conditions:

-

Correct displacement and rotation direction for the machine’s drive system or hydraulic circuit — if the rotation is wrong, the pump will perform incorrectly or even damage the system.

-

Mounting and shaft interface compatibility with the machine’s engine/hydraulic module integration. If the gear pump is not properly fitted, alignment issues or leakage may occur.

-

Pressure and flow rating aligned with machine demand. While gear pumps may not hit the highest pressures of piston pumps, they are sufficient for many Bobcat circuits. For example, Bobcat offers a “High Flow Triple Gear Pump 7409991” explicitly for skid steer/track loader hydraulic systems.

-

Serviceability in the field: Because mobile machines like Bobcat units often work in remote or rugged environments, using a pump type that is easier to source, replace, or maintain can reduce downtime.

Key Specifications of Bobcat Gear Pumps

OEM Part Number and Machine Fitment

-

Always start with the OEM part number, for example Bobcat lists part no. 7409989 (Double Gear Pump) for certain applications.

-

Another genuine Bobcat gear pump listing: part no. 6686703 (cast-iron gear pump for skid steer/track loader) in the Bobcat catalog.

-

Why it matters: matching the part number ensures that the mounting interface, shaft type, flange and service orientation align with the machine’s hydraulic system.

Displacement & Flow Rate

-

Displacement (measured e.g., in cc/rev or cubic inches per revolution) dictates how much fluid the pump delivers per shaft turn.

-

Flow rate (usually expressed in gallons per minute – GPM) is derived from displacement * rpm. For example in forums discussing Bobcat gear pumps, an original pump spec was noted at 6.8 GPM on one loader.

-

Why it matters: If you install a pump with lower displacement than required, you may suffer insufficient flow for attachments or drive circuits. If too high, system pressure or components may be stressed or the machine may run inefficiently.

Rotation Direction & Shaft Type

-

Gear pumps have to match the machine’s rotation direction: clockwise vs counter-clockwise (CW vs CCW). One aftermarket listing for Bobcat replacement part 6650678 specifies “counter-clockwise (left) rotation.”

-

Shaft spline, keying or coupling interface must align with the drive motor or engine output shaft.

-

Why it matters: Incorrect rotation means the pump may run in reverse, fail to build pressure properly, cavitate, or cause severe damage. Mis-matched shaft or mounting can lead to misalignment, leaks or bearing damage.

Mounting Interface & Construction Materials

-

Confirm the mounting flange geometry (bolt pattern, number of bolts), overall length/height, port location (inlet/outlet), and port sizes.

-

Construction material: Cast iron, ductile iron or aluminium could be used based on pressure rating and application. For example, part 6686703 is described as a “cast iron gear pump” in the Bobcat catalogue.

-

Why it matters: Correct mounting prevents mechanical stress, vibration and leaks; material choice affects durability and suitability for workloads (e.g., high pressure or harsh environments).

Pressure Rating (Continuous and Peak)

-

Though many gear pumps are marketed for “moderate” pressures, you should verify the continuous and intermittent maximum pressures the pump supports.

-

Example: Bobcat’s “High Flow Triple Gear Pump 7409991” features a “pressure-balanced design” for demanding applications.

-

Why it matters: If pump’s pressure rating is too low, you risk failure under load; if it’s over-specified but mismatched to system, cost may be higher than needed.

Troubleshooting Common Issues with Bobcat Gear Pumps

Common Symptoms & Their Causes

-

Loss of power / reduced hydraulic flow — Operators may notice that lift arms move slowly, attachments respond sluggishly, or travel speed is reduced. According to diagnostic guidance, changes in machine behaviour are among the first warning signs of pump problems.

-

Excessive noise or vibration — Strange knocking, whining or vibration from the hydraulic system often means internal wear (bearings, gear clearances) or cavitation (air entrainment).

-

Overheating of pump or hydraulic oil — When the pump operates outside its optimal specs, fluid circulation is compromised, resulting in heat build-up. One source notes that overheating is a common indicator of pump distress.

-

Leaks or foaming in hydraulic fluid — Seal failure, pump internal wear, or suction side issues (air ingress) can lead to foaming fluid or visible leaks. Forums discussing Bobcat hydraulics highlight these as root causes of performance issues.

Diagnostic Checklist

To properly troubleshoot pump issues, follow a systematic method:

-

Check fluid condition & level — Ensure hydraulic reservoir is filled to correct level, inspect fluid for contamination (metal particles, foam, darkening) and verify correct viscosity.

-

Measure system pressures/flow — Use calibrated gauges to compare actual pressure and flow against OEM or specification values. Deviations may signal internal pump failure.

-

Inspect suction side & filters — A common problem is insufficient suction feed or air in suction lines, which causes cavitation and damage. In one user case, a hidden filter on a Bobcat caused overheating.

-

Assess mounting, alignment & rotation direction — Ensure the pump is mounted properly, shaft coupling is correct, rotation direction matches machine requirement; mismatches lead to damage.

-

Check for internal damage — If external checks don’t reveal the problem, remove the pump and inspect gears, housing for scoring, excessive clearances or worn bearings. (Mechanic advice cited for Bobcat mini-excavator)

When to Repair vs Replace

-

Repair may be viable if you detect early wear: for instance seal kits, bearing replacement, cleaning contamination.

-

Replacement is recommended when:

-

The pump housing is scored or gears severely worn.

-

Clearance is out of factory spec and flow/pressure loss is significant.

-

The cost and downtime of multiple repairs exceed replacement investment.

-

The machine is critical and needs dependable uptime.

As one article summarises: ignoring the signs (noise, heat, leaks, loss of power) only increases cost and downtime.

-

Conclusion & Call to Action

In summary, selecting the correct gear pump for a Bobcat machine is far more than a simple parts swap. It requires precise matching of specifications — displacement, rotation direction, mounting interface, pressure rating and fluid compatibility — to ensure reliable performance and long service life. As we’ve seen, gear pumps deliver predictable, fixed-volume flow per revolution, making them an ideal fit for many mobile hydraulic systems.

If you operate Bobcat skid-steers, compact loaders or telehandlers and are seeking a reliable gear pump replacement — Poocca is ready to help. We offer:

-

Full cross-reference of Bobcat OEM gear pump part numbers

-

Models built to match displacement, rotation, shaft/mounting geometry

-

Quality manufacturing, warranty protection and global logistics

-

A cost-effective alternative to high-price OEM units, without compromising fit or performance

Contact Poocca today for a quote, specification match or custom gear pump solution engineered for Bobcat applications. Let us help you ensure your hydraulic system is powered by the right component — first time.

FAQ (Frequently Asked Questions)

Q1. What is the difference between a gear pump and a piston pump in a Bobcat hydraulic system?

A: A gear pump is a fixed-displacement positive-displacement pump: each revolution delivers a set volume of fluid, and it’s comparatively simpler in construction. Piston pumps (especially variable-displacement types) can adjust flow and pressure more dynamically. Gear pumps are widely used where robustness and predictability matter — piston pumps are used where higher pressures, variable flow or efficiency benefits are required.

Q2. How often should a gear pump in a Bobcat machine be replaced or serviced?

A: There is no one-size-fits-all interval, since life depends on operating conditions (load, contamination, fluid quality, machine hours). But best practice is to monitor pump performance (flow/pressure), inspect for unusual noise/heat/leakage, keep hydraulic fluid clean and maintain filters. Early signs of degradation (e.g., reduced flow, increased temperature, noise) mean service or replacement is due — delaying may increase downtime or cost.

Q3. Can I install any gear pump and make it work on my Bobcat machine, or does it have to match the OEM number exactly?

A: You don’t always need to use the OEM number itself, but any replacement must match the key specs of the original: displacement/flow, rotation, mounting geometry, shaft interface, pressure rating and fluid compatibility. A pump that physically fits but differs in these critical specs may cause performance issues or system damage.

Q4. What happens if I install a gear pump with the wrong rotation direction or wrong displacement?

A: Installing with wrong rotation may mean the pump runs “backwards”, generating reduced or no flow, causing cavitation, seal or bearing failure. Wrong displacement might deliver too little or too much flow, affecting machine speed, pressure loads and component wear. As one FAQ source says: “reversed rotation can lead to reduced flow, noise, seal failure, bearing failure.”

Post time: Oct-28-2025