Introduction

Among the many types of positive displacement pumps, bidirectional gear pumps are a specialized solution designed for systems where flow direction can reverse without needing extra valves or additional pumps.

What sets a bidirectional gear pump apart is simple but powerful: it’s designed to operate reliably in both rotational directions — clockwise (CW) and counterclockwise (CCW) — delivering flow in either direction through the same pump body. In a conventional (unidirectional) gear pump, reversing rotation or flow direction can lead to poor performance, internal damage, or system failure because the internal clearances, port design, and auxiliary components (such as relief valves or lubrication paths) are optimized for one direction only.

In contrast, a true bidirectional gear pump is engineered so that the inlet becomes the outlet and vice versa when shaft rotation is reversed, without compromising performance. This unique capability makes them ideal for applications like hydraulic circuits with forward/reverse actuators, reversible fluid transfer systems, metering processes requiring back-flush cleaning, or mobile equipment where flexibility and simplicity matter most.

How Bidirectional Gear Pumps Work

To understand a bidirectional gear pump, you must first grasp the basic working principle of a traditional gear pump and then see what adaptations are made so that it can operate reliably in both directions.

Gear Pump Fundamentals

At their core, gear pumps are positive displacement pumps — meaning they deliver a fixed volume of fluid for each revolution of the gears. In the most common external gear design, two gears mesh inside a closely-fitting housing. As the gears rotate:

-

On the inlet side, the gears separate, creating a low-pressure zone that draws fluid into the pump.

-

The fluid becomes trapped in the cavities between gear teeth and the housing.

-

On the discharge side, the gears re-mesh, reducing volume and forcing fluid out under pressure.

This mechanism delivers smooth and predictable flow proportional to rotational speed, a key reason gear pumps are widely used in hydraulic systems.

What Makes a Gear Pump Bidirectional

Most standard gear pumps are designed to run in only one rotational direction — meaning they are optimized so that fluid enters through a designated inlet port and exits through a designated outlet port. If the rotation is reversed on such a pump, performance can drop significantly or the pump can be damaged, because internal clearances, lubrication paths, and relief valve orientation are not intended for reverse flow.

A bidirectional gear pump, by contrast, is purpose-built so that both clockwise (CW) and counterclockwise (CCW) shaft rotation produce usable fluid flow — and leakage paths, sealing geometry, and port symmetry support this reversed operation without modification.

Key design features include:

-

Symmetric or reversible internal pathways so that inlet and outlet functions swap cleanly when rotation changes.

-

Valving or port design that maintains pressure and flow characteristics in both directions (in some designs this includes one-way check valves or dual relief valve arrangements).

-

Balanced lubrication paths so that bearings and shaft seals are properly lubricated regardless of rotation.

Because of these design elements, when you reverse the drive direction, the pump simply draws fluid from what was previously the outlet port and pushes it out through what was previously the inlet port — all without damaging internal components.

Performance Specifications and Design Data

Below is a comparison of typical bidirectional gear pump specifications from industrial-grade hydraulic pumps widely used in mobile and industrial hydraulic systems. These representative specs help you understand common performance ranges when selecting the right pump for your application:

| Specification | Model / Example | Value / Range |

|---|---|---|

| Displacement | CBHL-2000 (industrial) | approx. 50 cc/rev |

| CBHST1-ISO Series | 90–110 cc/rev | |

| Rated Pressure | CBHL-2000 | 25 MPa (≈3625 psi) |

| CBHST1-ISO | 20–22 MPa (≈2900–3190 psi) | |

| Max Pressure | CBHL-2000 | 28 MPa (≈4060 psi) |

| CBHST1-ISO | 25 MPa (≈3625 psi) | |

| Rated Speed | CBHL-2000 | 2200 r/min |

| CBHST1-ISO | 2000–2200 r/min | |

| Max Speed | Industrial series | 2500 r/min (common) |

| Housing Material | Typical industrial pumps | Cast iron |

| Rotation | All listed models | Bidirectional (reversible) |

Core Applications Where Bidirectional Gear Pumps Shine

A bidirectional gear pump isn’t just a technical novelty — it solves real problems in hydraulic systems where fluid direction must reverse without adding complex valve arrays or multiple pumps. Below are the most impactful application areas where these pumps deliver practical value, reduced system cost, and enhanced reliability.

Fluid Transfer with Fill/Unload Cycles

In many industrial and process applications, you need to fill a vessel, tank, or reservoir and later empty it or purge the line. Traditionally, this would require separate circuits or a directional valve network.

A bidirectional gear pump simplifies this by allowing the same pump to push fluid into a tank and then pull it back out in reverse flow, eliminating extra valves and reducing piping complexity.

Example use cases:

-

Cleaning or flushing pipelines without additional flushing pumps

-

Batch processing tanks that need alternating fill and drain cycles

-

Transfer lines in chemical dosing systems

Mobile Hydraulic Machinery (Construction, Forklifts, Agriculture)

Bidirectional gear pumps are widely used in mobile and off-highway equipment, where reversing flow direction is a common need.

Key advantages in mobile systems:

-

Simplified circuits: Reduces the need for multiple directional control valves

-

Higher uptime & efficiency: Direct flow reversal boosts cycle speed

-

Lower maintenance cost: Fewer valves and fittings mean fewer failure points

Practical application examples:

-

Forklifts: Lifting and tilting operations benefit from reversible flow for accurate positioning.

-

Construction machinery: Boom and arm controls may require forward and reverse fluid flows during operation cycles.

-

Agricultural equipment: Implements such as loaders and plows often operate in both directions during field work.

Metering, Dosing & Precision Processes

Where fluid delivery must be precise, repeatable, and sometimes reversed for cleaning or adjustment, bidirectional gear pumps are ideal due to their positive displacement nature and predictable volumetric output.

They are frequently chosen for:

-

Chemical dosing systems that require accurate fluid delivery and occasional back-flush

-

Food and beverage manufacturing where sanitary cleaning cycles require bidirectional flow

-

Ink and paint dispensing systems where reversing helps clear nozzles or lines

The pump’s consistent displacement per revolution ensures high metering accuracy in both forward and reverse flows, reducing calibration challenges.

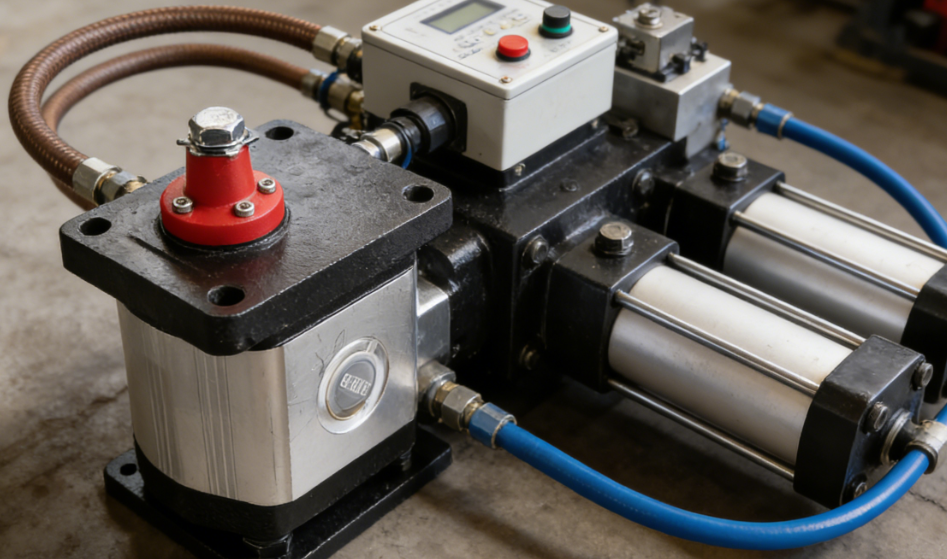

Hydraulic Power Units with Reversible Functions

In Hydraulic Power Units (HPUs) and Electro-Hydraulic Actuation systems (EHA), bidirectional gear pumps can streamline design by eliminating the need for discrete directional valves or pumps for reverse motion.

Benefits include:

-

Reduced control complexity

-

Lower system cost

-

Higher reliability due to fewer mechanical components

Such units are common in industrial presses, winch and hoist control systems, and machinery with double-acting hydraulic cylinders where both directions of motion are required.

Systems Requiring Line Purge or Back-Flow Capabilities

In certain process industries, fluid lines must be purged, back-flushed or cleared to maintain product quality or prevent blockages. A bidirectional gear pump makes this possible without additional valves or bypass circuits.

This application is particularly relevant in:

-

Chemical processing

-

Pharmaceutical dosing lines

-

Food grade fluid circuits

Here, the pump’s ability to seamlessly switch flow direction enhances system hygiene, reduces downtime, and simplifies maintenance planning.

Bidirectional vs Unidirectional Gear Pumps — Professional Comparison

Feature Comparison Table

| Feature / Aspect | Bidirectional Gear Pump | Unidirectional Gear Pump |

|---|---|---|

| Flow Direction | Supports forward and reverse flow | Supports only single direction flow |

| Rotation Requirements | Designed to run reliably in both CW & CCW | Optimized for one rotation; reverse may reduce life or cause issues |

| System Complexity | Lower — fewer valves needed when flow reversal is required | Higher — often requires additional control valves |

| Cost (System‑Level) | Lower overall due to simplified circuitry | Can be higher due to added components |

| Flexibility | High — ideal for systems with frequent reversal | Standard — best for fixed‑direction systems |

| Directional Control | Internal design inherently supports reversal | Requires external directional valves |

| Installation Ease | Easier when system design expects bidirectional cycles | Straightforward for one‑way flow systems |

| Application Scope | Reversible circuits, fluid transfer, mobile hydraulics | Traditional fixed flow hydraulic and lubrication systems |

| Common Misconceptions | “Performance identical in both directions” → Not always unless designed for it | “Any gear pump can be reversed” → False; may damage non‑reversible types |

How to Choose the Right Bidirectional Gear Pump

1. Flow & Pressure Requirements

Start with the basics:

-

Flow rate (L/min or GPM) — ensure the pump’s displacement and rated speed meet your system’s flow demands.

-

Maximum system pressure — the pump’s pressure rating should exceed peak operating pressure with a safety margin.

This ensures the pump will deliver required performance in both forward and reverse operation.

2. True Bidirectional Capability

Not all gear pumps are equal:

-

Confirm that the pump’s internal design supports both directions of rotation without compromising lubrication, seals, or pressure protection — not all “reversible” pumps perform equally in both directions.

This prevents premature wear and performance loss when switching directions.

3. Fluid Properties & Compatibility

The fluid you’re pumping directly affects pump life:

-

Viscosity: Very low viscosity fluids may increase internal leakage, high viscosity may increase torque requirements.

-

Temperature & chemistry: High/low temperatures and corrosive fluids require appropriate materials and seal types.

Matching the fluid with the correct materials and clearances ensures lasting performance.

4. Suction Conditions & Piping

Because bidirectional pumps reverse flow paths:

-

Check suction lines, Net Positive Suction Head (NPSH) and piping geometry for both forward and reverse operation.

-

What was discharge becomes suction when reversed — this must be acceptable in your system design.

5. Drive Speed & Power

-

Choose a pump whose rated speed (RPM) matches your drive source (motor or drive shaft).

-

Stay within recommended speed ranges to avoid excessive wear or cavitation.

This ensures efficiency and long service life.

6. Economic & Lifecycle Considerations

Don’t only compare purchase prices — consider:

-

Maintenance and spare parts availability

-

Serviceability and ease of repair

-

Total cost of ownership, including downtime and service costs

A more reliable, slightly higher‑cost pump can be more cost‑effective over its lifetime.

7. Standards & Compatibility

Ensure the pump:

-

Fits your mounting pattern (e.g., ISO/SAE)

-

Uses materials and certifications necessary for your industry (e.g., corrosion resistance, high temperature)

This avoids integration problems later.

FAQ Section — Expert Answers

Q1: Can any gear pump be used in both directions?

Answer:

No — only pumps specifically designed for bidirectional operation can reliably run in both clockwise (CW) and counter‑clockwise (CCW) directions. Standard gear pumps are optimized for a single direction, and reversing them can lead to poor performance or damage unless they are built for reversible use. Always check manufacturer specifications before attempting to run the pump in reverse.

Q2: Does the flow rate and performance stay the same when reversed?

Answer:

Not necessarily. Even though a pump may be designed for bidirectional operation, its actual performance (efficiency, flow rate, internal leakage) can still differ between forward and reverse due to internal clearances, relief valve arrangement, and lubrication paths. A true bidirectional pump should minimize these differences, but slight variations may still exist.

Q3: Can a bidirectional gear pump be used as a hydraulic motor?

Answer:

While some reversible gear pumps can temporarily function as a motor, they are not engineered to replace a dedicated hydraulic motor for long‑term or heavy‑duty motor use. Their bearing, sealing, and pressure capacity are designed primarily for pumping, and prolonged motor operation can lead to frequent failures.

Q4: What fluids can a bidirectional gear pump handle?

Answer:

Gear pumps perform best with clean, well‑filtered, lubricating fluids such as hydraulic oil. They are generally not suitable for dirty, abrasive, or highly corrosive fluids, as these can damage internal gears and seals, increase wear, and reduce service life. If your application involves particulates, consider filtration systems or alternative pump types.

Q5: Do I need relief valves in both directions?

Answer:

Yes, if you intend to run a bidirectional pump in both directions routinely. Many gear pumps have integrated relief protection for one direction only. If you reverse flow regularly, your system must have appropriate over‑pressure protection for both directions to protect the pump and other components.

Q6: Can reversing the pump damage seals or internal parts?

Answer:

If the pump is truly designed for bidirectional use, reversing should not harm the pump. However, if you reverse a standard unidirectional pump, or if auxiliary internal features (like relief valves or seals) aren’t rated for reverse operation, you could damage seals, compromise lubrication paths, or accelerate wear. Always confirm bidirectional suitability.

Conclusions and Recommendations

Bidirectional gear pumps provide a practical solution for applications where fluid flow must be reversed reliably and efficiently. These pumps are engineered to operate in both clockwise and counter‑clockwise rotation, enabling forward and reverse flow without the need for extra valves or multiple pump units. Their design flexibility and predictable displacement per revolution make them suitable for fluid transfer, mobile hydraulic systems, metering, and equipment that requires reversible flow control.

To get the best performance from a bidirectional gear pump, define your system’s flow and pressure requirements, confirm the pump’s ability to operate in both directions, ensure the fluid and suction conditions are compatible, and match the drive speed to the pump’s operational range. Proper selection, installation, and fluid compatibility will ensure long service life and stable operation.

If you are designing or upgrading a hydraulic system that requires reversible flow, choosing a pump built specifically for bidirectional operation can simplify your system, reduce overall cost, and improve system reliability. Investing in the right pump upfront and working with experienced engineers can help you avoid common pitfalls and optimize performance.

Poocca Hydraulic has over 20 years of experience in the hydraulic industry, offering a wide range of high‑quality hydraulic products including gear pumps, piston pumps, vane pumps, motors, valves, and related components.

Poocca’s bidirectional gear pumps, such as the PA‑0.25/0.5 series, are designed to achieve high efficiency, reliable bidirectional performance, and excellent volumetric and mechanical efficiency. These pumps support a range of displacements, standard flange ports, and are suitable for hydraulic power units, lubrication systems, mobile equipment, and other reversible flow applications.

In addition to bidirectional models, Poocca provides both external and internal gear pumps, high‑pressure gear pumps, and customized options to fit different application needs and operating environments. All products undergo rigorous testing before shipment to ensure quality and reliability.

If you need help selecting the right bidirectional gear pump for your application or want a tailored solution, Poocca’s technical team offers professional consultation, custom configurations, and fast delivery to meet your project requirements. Contact us to get expert support and a competitive quote.

Post time: Dec-18-2025