Introduction & Quick Primer on Gear Pumps

What is a Gear Pump?

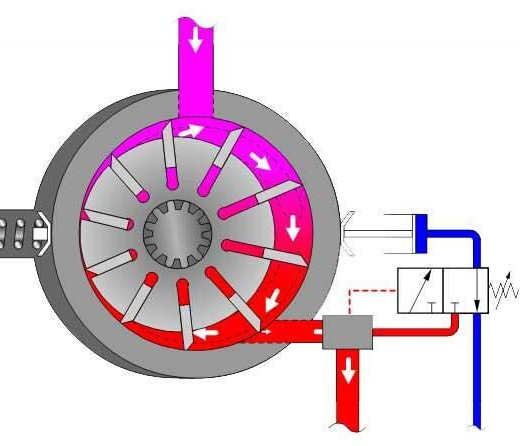

A gear pump is a type of positive-displacement pump – meaning it moves a fixed volume of fluid for each revolution of its mechanism.

Here’s how the short version goes:

-

Two (or more) intermeshing gears rotate inside a closely-fitted housing.

-

At the inlet side, as the gears separate, they create a low-pressure cavity that draws in fluid.

-

The fluid is carried around the outside of the gear teeth (in external gear designs) or between the teeth and a casing (in internal gear designs).

-

At the outlet side, as the gears re-mesh, the volume is reduced and the fluid is forced out under pressure.

So far so mechanical? Yes – but this clever little mechanism packs serious industrial punch.

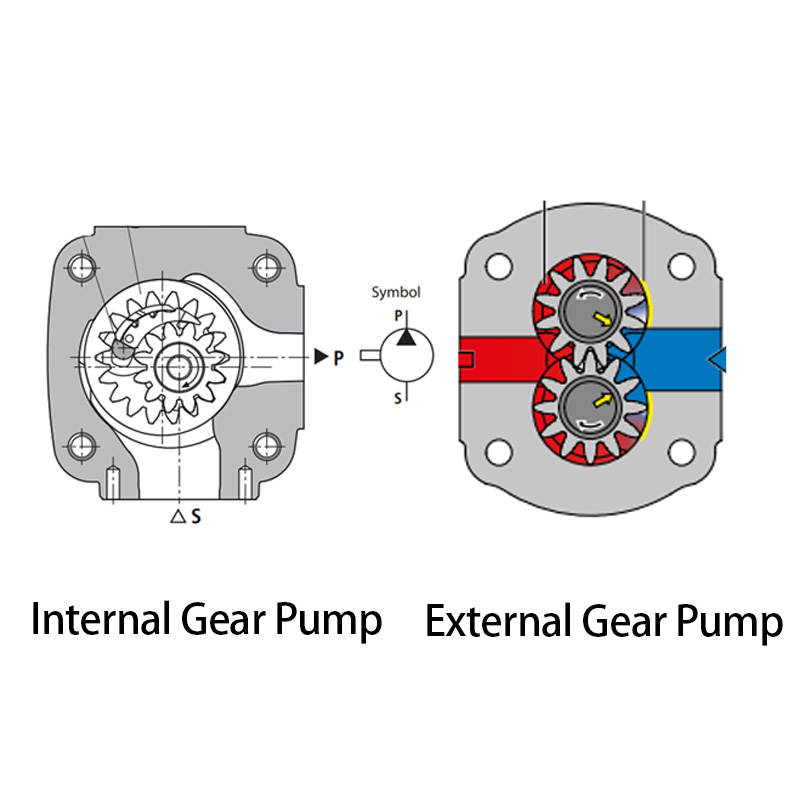

Two Main Flavors: External vs Internal Gear Pumps

Let’s give the soups names so you know what’s heating on the stove:

-

External Gear Pump: Two identical spur gears (or helical/herringbone variants) mesh side by side, each on its own shaft. The fluid flows around the outside of the meshing region and is expelled when the teeth come together.

-

Internal Gear Pump: A larger gear (rotor) contains a smaller gear (idler) inside it; the idler is offset, and a fixed crescent seals the void as fluid moves between the gears. This design often offers better suction performance, especially for viscous fluids.

What Does “Bidirectional” Mean in Gear Pumps?

Defining “Bidirectional” for Gear Pumps

In the realm of gear pumps, “bidirectional” means the pump is designed to handle both directions of rotation of its drive shaft — and consequently, both flow directions through the pump. In other words, you can flip the drive motor or find conditions where the flow reverses, and the pump still works reliably.

For example, one manufacturer explicitly states:

“Reversible (bidirectional or bisensel) … aluminium and external gear hydraulic pumps. … meaning that the pump is made to work in both directions, without any modification.”

Not every gear pump on the market offers this. Many are designed to run in only one direction of rotation and one flow direction. Running them “backward” may cause performance loss or damage.

What “Bidirectional” Doesn’t Automatically Guarantee

Though the term sounds straightforward, here are some caveats you’ll want to keep in mind:

-

It must be designed for both directions: As one source warns: “Before you turn that ‘reverse’ switch … check whether your pump is really designed to run in both directions.”

-

Performance may differ: Even if the pump supports reverse flow, its performance (flow rate, efficiency, wear) might not be identical in both directions unless specifically engineered for that.

-

Auxiliary features may still be directional: Things like relief valves, seal-circulation systems, internal lubrication paths can be designed for one direction. If you reverse the flow/rotation, they might not function optimally unless accounted for. For example:

“Many of the relief valves … are directional. They only provide over-pressure protection in one direction … when changed to bidirectional use, both sides must be protected.”

-

Suction and discharge conditions change: When you reverse the pump, what was the discharge line now becomes the suction line (and vice versa). That means performance and installation conditions (NPSH, suction geometry, pipe lengths) must be checked for both directions.

How Does a Bidirectional Gear Pump Work?

The Basic Mechanism (in a Forward Direction)

Let’s start with the familiar: how a standard gear pump works in one direction.

-

In an external gear pump, two identical gears mesh inside a housing. One is driven by the motor (“driver gear”) and the other is turned by the first (“driven gear”).

-

As the gears rotate, on the inlet side they unmesh (teeth separate) → this expansion creates a low‐pressure cavity that draws fluid in.

-

That fluid is “carried” around the outer periphery of the gears (in external types) or through the internal volume (in internal gear types).

-

On the discharge side, the gears mesh again (volume shrinks) → fluid is forced out through the outlet port under pressure.

-

Because of tight clearances between the gears and housing, there is minimal back-flow (slip), so the flow rate remains predictable.

If it helps, imagine two dancers (the gears) swirling around each other inside a tight ring (the housing). As they move apart they “invite” fluid in; as they come back together they “squeeze” it out. That’s the core motion.

Reversible Operation: What Changes for Bidirectional Flow

When you switch to a bidirectional gear pump — i.e., a pump explicitly designed to handle both clockwise (CW) and counter-clockwise (CCW) rotation, giving you flow in both directions — here are the key operating considerations:

1. Flow path swap

-

In a reversible pump, when you reverse the drive shaft’s direction, the “inlet side” becomes the “outlet side” and vice versa, because the gears now unwind/mesh in the opposite rotational sequence.

-

The pump must be designed such that the port designated as “inlet” in forward mode can function as the outlet in reverse mode (or the system must be configured so this swap is intentional).

2. Sealing, clearances & internal geometry

-

Because the flows reverse, the gear and housing clearances, seal positions, relief valves, internal lubrication paths must all tolerate operation in both directions. Otherwise you risk leakage, poor suction, or improper pressure relief.

-

For example, in one article about gear pumps it is noted how performance depends heavily on clearances: “As clearances increase … there is a gradual reduction in efficiency and increase in flow slip.”

-

Some pumps might include dual one-way valves or symmetric relief systems so that both directions are safe.

3. Suction/discharge side conditions

-

When reversed, what was the discharge piping may become suction piping. That means things like NPSH (net positive suction head), pipe length/resistance, fittings, and any suction prerequisites must be checked for both directions of flow.

-

Simply reversing the motor without verifying the system may lead to inadequate suction, cavitation, or unintended backflow.

4. Performance differences

-

Even if a gear pump is marked “bidirectional”, its performance in reverse might not perfectly mirror its forward performance (unless explicitly engineered). Factors like gear tooth profile, port geometry, and load may cause slight differences.

-

A research note on reversible internal gear pumps observed that “the symmetrical oil suction and discharge chambers and the reversing rotation condition … result in low oil …” (hinting that design must deliberately account for reverse conditions)

Walk-through: Step by Step for Reversal Operation

Here’s how it plays out, step by step, when you operate a bidirectional gear pump:

-

Drive direction selected: You choose the shaft rotation (CW for forward; CCW for reverse) based on system piping and desired flow direction.

-

Inlet port opens: With the new direction, the gear teeth separate on what is now the “intake” side → fluid is drawn into the pump cavity.

-

Trapping & transfer: Fluid gets carried between gear teeth and casing from the intake side to the new discharge side, following the reversal path.

-

Discharge: The gear teeth mesh on the discharge side, reducing the volume and pushing fluid out via the outlet port.

-

Check system interface: Because the piping has reversed roles, ensure the system is ready for that — check for proper valve positions, that the “old” suction line can handle the new flow, etc.

-

Monitoring & maintenance: After reversing, monitor for any unusual noise, vibration or leakage (which might indicate that the pump or system isn’t optimized for reverse mode).

Advantages & Limitations of Bidirectional Gear Pumps

Advantages

-

Greater system flexibility — Because a bidirectional gear pump can handle flow in both directions (forward and reverse), it gives you more options in how you design your system. You could use the same pump for filling a vessel and then emptying it in reverse, for example.

-

Simplified piping / fewer components — With standard unidirectional pumps you might need additional valves or pipe loops to reverse flow. A purpose-built bidirectional pump can reduce that complexity, which can save space, cost, and maintenance.

-

Precise and consistent flow control — Gear pumps in general are positive displacement machines: flow is closely tied to rotation, giving predictable volume per revolution. This is especially useful in dosing or metering applications.

-

Good for viscous fluids / challenging fluids — Many gear pumps handle thick or high-viscosity fluids well (which many other pump types struggle with). This means in a bidirectional design you get that plus the extra directional flexibility.

-

Compact footprint / robust design — Because gear pumps have fewer large moving parts compared to some other pump types, they can be relatively compact and durable. For systems where space is at a premium or where you want something rugged, that’s an advantage.

Limitations / Things to Watch

-

Not all gear pumps are truly bidirectional — Just because a pump looks symmetric doesn’t guarantee the manufacturer designed it for reversing rotation and flow. If used in reverse without that design, you may face poor performance or damage.

-

Wear, especially with abrasive or solid-laden fluids — Gear pumps rely on tight clearances for efficiency. If you have abrasive particles or suspended solids, or you reverse frequently in a system not optimized, wear can accelerate.

-

Performance in reverse may differ — The pump may offer bidirectional capability, but the efficiency, leakage (slip), priming/suction conditions might not exactly mirror forward direction unless explicitly designed for that.

-

Flow/pressure limitations — While gear pumps are terrific for many applications, they may not always be the best for extremely high flow rates or extremely low‐viscosity fluids, especially when reversing. Some sources cite limited operational ranges.

-

Installation and system design matter — Because you’re dealing with reverse flow, you must ensure the piping, valves, suction/discharge geometry, relief valves, and seals are appropriate for both directions. If the system was only designed for one direction, reversing could cause cavitation, inadequate suction or leakage.

-

Noise, sealing wear and higher maintenance in some cases — Due to tight tolerances and metal-on-metal gear contact, noise and sealing challenges can be issues, particularly if the pump runs in less‐than‐ideal conditions (e.g., very low viscosity fluid, high speed, or reverse usage not intended by design).

Quick Summary Table

| Aspect | Benefits | Cautions |

|---|---|---|

| Flexibility | One pump can serve forward & reverse flow | Must ensure pump & system support reversal |

| Flow precision | Predictable displacement per revolution | Clearances, slip and performance may vary in reverse |

| Viscous fluid handling | Good for thick fluids | Might struggle with very thin fluids or solids |

| Piping & system simplicity | Fewer extra valves or loops needed | System must still accommodate reversal geometry |

| Durability & size | Compact, fewer large moving parts | Wear & maintenance might increase under harsh use |

Typical Applications of Bidirectional Gear Pumps

Key Application Areas

Here are several scenarios where a bidirectional (or reversible) gear pump shines:

-

Fluid transfer with fill/unload cycles

For example, when a system needs to fill a tank or container and later empty it or purge the line, one pump capable of forward and reverse flow reduces the need for separate pumps. One manufacturer highlights such reversible gear pumps as suitable for agricultural, transport and earth-moving applications. -

Hydraulic systems in mobile equipment

In mobile or construction vehicles that operate cylinders or motors in both directions, the need to reverse flow is common. A bidirectional gear pump is an ideal fit because it simplifies design by avoiding extra directional-valving hardware. -

Metering and dosing processes

When precision is required — and when you may need to reverse flow (for back-flush, cleaning, change-out) — gear pumps with reversible capability are beneficial. External gear pumps are frequently used for dosing in industries like food, inks, and chemicals because of their accuracy. -

Systems requiring line stripping or pressure reversal

In certain process lines, after completing a forward transfer, you might need to reverse the flow to clear or clean the line. The bidirectional gear pump enables this without adding second dedicated infrastructure. A news piece describes how gear pumps can “operate in both directions of rotation” to serve fluid transfer in hydraulic systems needing back-flow prevention.

Concrete Product Example That Illustrates the Use

One model product emphasises how a bidirectional gear pump is constructed for such versatile usage:

-

The Rotontek CBST Bidirectional Gear Pump offers displacement from 0.25–1.5 cc/rev, rated pressure up to 20 MPa, and is described as suitable for “small and medium-sized hydraulic power units and EHA systems”.

-

The Vivoil “Reversible (bidirectional) external gear hydraulic pumps” line specifies displacement from 0.16–86.87 cm³/rev and maximum pressure up to 320 bar—covering heavy industrial applications.

How to Select a Bidirectional Gear Pump: Key Specifications & Considerations

Important Specifications to Review

Here are the key parameters and design-features you should evaluate (and ask your pump vendor about) when choosing a bidirectional gear pump:

-

Flow rate / displacement: How much fluid per revolution (e.g., cc/rev) or per minute (L/min or GPM). Make sure the pump’s rated displacement meets your system demands in both directions.

-

Maximum pressure (and differential pressure): What is the highest pressure the pump must overcome? Does the vendor specify the maximum pressure rating for reverse flow as well?

-

Rotation speed (RPM) and directionality: The pump should be able to operate at the required speed and allow both CW and CCW if bidirectional operation is truly needed.

-

Viscosity and fluid characteristics: The fluid’s viscosity, temperature, presence of solids or abrasives matter a lot. Gear pumps perform differently based on fluid properties.

-

Suction conditions / NPSH: Particularly for reverse operation, what was the discharge line may become the suction line. Ensure the system has adequate NPSH (Net Positive Suction Head) in both directions.

-

Port orientation and symmetry: For true bidirectional usage, inlet/outlet ports should be capable of either role (or clearly rated for reversal). If the ports differ in size or layout, reverse flow may be problematic.

-

Relief valves, seals, lubrication paths: These auxiliary systems often assume one flow direction. When reversing, ensure they’re designed or configurable for both directions.

-

Materials & wear resistance: Especially if your fluid is abrasive or high-viscosity, ensure the gears, housing, seals are of appropriate materials. Also consider wear during reverse cycles.

-

Maintenance, reverse cycles & operational frequency: If you’ll be reversing frequently, the pump must be rated for such use; wear, internal clearances, and maintenance intervals matter.

Conclusion & Recommendation

We’ve explored what a gear pump is, what makes a bidirectional gear pump special, how it works, its advantages and limitations, how to choose one, and where it’s commonly used.

In short, a bidirectional gear pump offers real value when your system needs flow in both directions, but only if the pump and the system are properly selected and configured for that flexibility. Always check that the pump is explicitly rated for CW/CCW (clockwise/counter-clockwise) rotation, verify piping and suction/discharge conditions, and match the fluid and operating conditions carefully.

Why I Recommend Poocca Hydraulic (Shenzhen) Co., Ltd.

If you’re looking for a supplier or manufacturer to fulfil your gear pump needs, especially with customization or a broad model range, Poocca Hydraulic stands out for several reasons:

-

We are a comprehensive hydraulic service enterprise integrating R&D, manufacturing, maintenance and sales of hydraulic pumps, motors, valves and accessories.

-

We gear-pump offering is robust: They manufacture both external and internal gear pumps and have more than 1,600 product types.

-

Quality and production capacity are well emphasised: For example, they mention use of CNC hobbing, CMM inspection, automatic gear-checking machines, etc.

-

We provide customization options: Poocca states they can adjust sizes, port configurations, and other parameters to meet specific application requirements.

Therefore, if your project involves selecting a bidirectional gear pump and you need a manufacturer/supplier who can support custom variants and deliver at scale with accepted quality standards, Poocca Hydraulic is a recommended candidate to engage.

FQA

1. Q: Can a gear pump really operate in both directions of rotation and flow?

A: Yes — if it is specifically designed for it. Some gear pumps are built to run in both clockwise (CW) and counter-clockwise (CCW) rotation, thereby allowing flow in either direction.

However, many standard gear pumps are not reversible by default, so you must check the manufacturer’s specifications carefully.

2. Q: What must I check to ensure a gear pump is truly bidirectional?

A: Key items include:

-

Confirmation that the pump supports CW & CCW rotation (or flow in both directions).

-

That the inlet and outlet ports are capable of swapping roles when reversed (or designed symmetrically).

-

That valves, seal-circulation paths, and internal lubrication circuits are compatible with both flow directions.

3. Q: Are there any performance differences when a gear pump runs in reverse vs forward?

A: Yes — even pumps designed for reversible operation may show differences in performance, efficiency, or wear when used in reverse. For example, suction conditions and port geometry may not be optimized for the non-primary direction.

Therefore, it’s wise to verify performance specs for both directions when you plan to use reversal frequently.

4. Q: What are typical applications where a bidirectional gear pump is especially useful?

A: These include:

-

Processes where you need to fill a tank and then empty it (one pump servicing both directions).

-

Hydraulic systems in mobile equipment where cylinders or motors reverse direction.

-

Systems that require line purging or back-flow cleaning so reverse flow keeps things flushed.

5. Q: What are common pitfalls or things to avoid with bidirectional gear pumps?

A: Some common issues include:

-

Using a non-bidirectional pump and trying to reverse it anyway — this can lead to seal failure, lubrication problems, or poor suction.

-

Neglecting to check suction conditions for reverse flow (what was once a discharge line now becomes suction).

-

Ignoring that auxiliary features (relief valves, flush plans) may only be set up for one direction.

-

Failing to consider abrasion or wear when switching direction frequently, which may shorten service life.

Post time: Oct-22-2025