In the world of positive displacement hydraulic pumps, vane pumps and gear pumps stand out as two of the most enduring, reliable, and widely used technologies. Both mechanisms—though distinct in design—offer precision flow control, dependable performance, and adaptability across a wide spectrum of industries, ranging from fuel transportation to manufacturing systems.

With a long legacy of coexisting in industrial use—sometimes even within the same system—vane and gear pumps are both proven performers; yet, choosing between them comes down to a detailed understanding of system requirements, fluid characteristics, and operational priorities.

Working Principle & Structural Overview

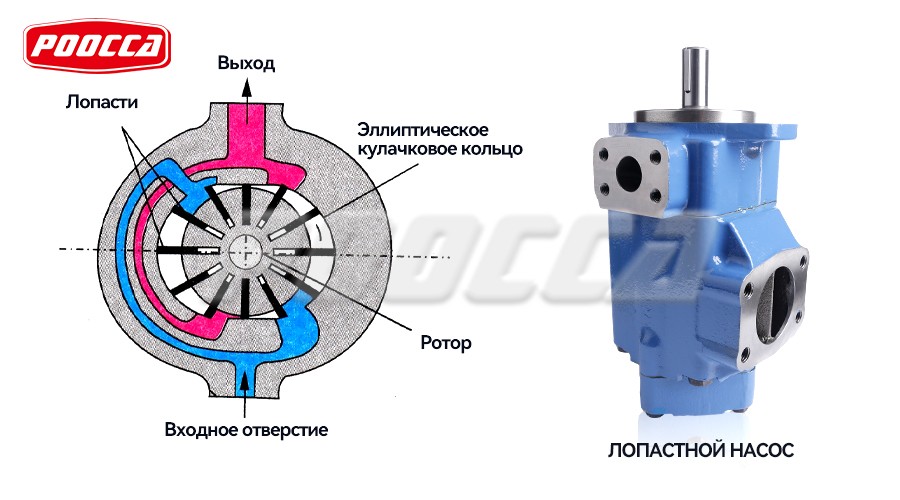

Vane Pump (Rotary Vane Pump)

A vane pump is a type of positive-displacement rotary pump. It consists of a cylindrical rotor with multiple radial slots, each housing a sliding vane. As the rotor spins within a cam ring, the vanes are forced outward—via centrifugal force and/or springs—maintaining tight contact with the pump casing and creating sealed chambers. These chambers expand and contract during rotation, producing suction at the inlet (drawing fluid in) and discharge at the outlet (compressing and expelling the fluid).

Key structural features:

-

Sliding vane rotor and cam ring: Form the primary moving parts and seal the fluid chambers.

-

Self-compensating design: As vanes wear, they extend further, preserving internal contact and efficiency.

-

Optional configurations: Includes unbalanced (eccentric rotor), balanced (elliptical cavity), and variable-displacement designs to suit different performance needs.

Advantages:

-

Excellent for thin to medium viscosity fluids

-

Low pulsation, smooth flow, good suction, and dry-priming capability.

Limitations:

-

Not ideal for highly viscous or abrasive fluids

- Complex construction involves numerous precision parts requiring clean operation and regular maintenance.

Gear Pump

A gear pump is another common positive-displacement pump, characterized by its simplicity and fixed displacement. Fluid is moved by the intermeshing teeth of two gears. As the gears separate at the inlet, they create a vacuum that draws in fluid; the fluid is then carried around the outer circumference of the gears and expelled when the teeth mesh again on the discharge side.

Key structural features:

-

Two main types:

-

External gear pumps: Two external gears driven by separate shafts.

-

Internal gear pumps: A smaller inner gear rotates within a larger outer gear, often with a crescent-shaped spacer to seal the fluid path.

-

-

Very tight clearances (≈10 µm) enhance efficiency and prevent backflow.

Advantages:

-

Simple, rugged, and highly reliable

-

Capable of handling high pressures and high-viscosity fluids

-

Efficient fixed flow delivery per revolution.

Limitations:

-

More flow pulsation and noise compared to vane pumps.

Displacement Types: Fixed vs. Variable in Vane and Gear Pumps

Fixed Displacement Pumps

-

Gear Pumps: Gear pumps are quintessential fixed-displacement devices. With each rotation of the gears, they deliver a precise and constant volume of fluid. This predictable performance simplifies system design and control.

-

Vane Pumps (some models): Certain vane pump configurations are also fixed-displacement, particularly the balanced vane designs. These maintain a constant output per revolution and are mechanically simpler.

Variable Displacement Pumps

-

Vane Pumps (unbalanced designs): A key advantage of vane pumps is that unbalanced configurations can be adapted into variable-displacement models. By adjusting the eccentricity between the rotor and cam ring—such as via a pressure compensator or external control—the volume per revolution can be modulated. This enables performance tuning, energy savings, and adaptive flow regulation.

-

Such variable designs have been successfully deployed in applications like automotive automatic transmissions, where adaptive flow control is vital.

-

-

Gear Pumps: In contrast, gear pumps remain strictly fixed-displacement. Their mechanical design does not accommodate variable displacement.

Efficiency & Reliability

Efficiency

-

Vane Pumps: A standout feature is their self-compensating vanes. As wear occurs, the vanes dynamically extend, maintaining intimate contact with the housing and preserving volumetric efficiency over long periods—even after millions of gallons pumped. This phenomenon is known as flow sustainment, and it ensures consistent delivery performance throughout the pump’s lifecycle.

Furthermore, vane pumps can operate dry (run without fluid) without immediate damage, thanks to a non-metal-on-metal design and low friction, which supports good efficiency in challenging conditions. -

Gear Pumps: Gear pumps are inherently efficient due to their tight gear clearances—in the realm of microns (~10 μm)—which minimize leakage and maintain strong displacement accuracy. This construction makes them particularly efficient in high-pressure and high-viscosity applications.

Reliability

-

Vane Pumps: Self-compensation is a key driver of long-term reliability. The vanes maintain constant sealing performance over time, resisting degradation in flow rate even in extensive service. Additionally, vane pumps are capable of dry starting and handling non-lubricating fluids or liquid-vapor mixtures without undergoing immediate wear or failure.

-

Gear Pumps: Known for their solid, straightforward construction, gear pumps offer robustness in demanding environments. They are well-suited to heavy-duty, industrial, and contaminated fluid scenarios, offering reliable performance with minimal maintenance complexity.

Maintenance Requirements

Vane Pumps

Maintaining vane pumps ensures long-term efficiency and reliability. Key tasks include:

-

Greasing Bearings Regularly: Inspect turbine bearings every three months. If grease levels are low, use a manual grease gun—stop greasing once grease appears at the relief port to avoid over-lubrication, which can compromise the mechanical seal.

-

Routine Part Inspections: Regularly monitor components like vanes, bearings, and gaskets. Replace parts showing signs of wear to maintain optimal performance.

-

Filter Checks & Cleanings: Regularly inspect inlet and exhaust filters. Replace or clean clogged filters to prevent contamination-related wear or reduced performance.

-

Visual Examination of Wear: Disassemble as required and clean internal parts carefully. Scrutinize for vane wear, cracks, and sealing degradation.

Takeaway: Vane pumps require routine lubrication, component monitoring, and filter management to maintain efficiency and prevent premature failure.

Gear Pumps

Gear pumps are rugged yet demand disciplined upkeep:

-

Daily Visual Inspections: Check for physical damage, leaks, loose bolts, or abnormal noise. Observe casing temperature—it should remain below approximately 60 °C. Deviations may signal overload, internal wear, or poor lubrication.

-

Bearing & Clearance Checks: Bearings should be inspected regularly. Excessive noise may signal wear. Use a thin paper to gauge gear-to-chamber clearance—values exceeding 0.005–0.007 inches indicate wear and require parts replacement.

-

Lubrication and Seal Maintenance: Follow manufacturer guidelines for bearing lubrication. Monitor oil condition and replace if degraded. Inspect seals and replace if leaking.

-

Installation and Operating Safeguards: Ensure secure mounting on machined, vibration-resistant bases. Include an overpressure protection valve (PRV) and a flow switch to prevent dry running, which can damage gear surfaces.

-

Comprehensive Overhaul Practices: During deep maintenance, disassemble the cover carefully, clean parts (e.g., with kerosene), and check critical components like gear tips, bearings, and seals for wear or damage.

Cost-Effectiveness

Initial Purchase Cost

-

Gear Pumps: Typically range from $100 to $2,000, making them a budget-friendly option for many applications.

-

Vane Pumps: Generally priced between $200 and $3,000, reflecting their more complex design and manufacturing processes.

Long-Term Operational Costs

-

Gear Pumps: While initially less expensive, gear pumps may incur higher maintenance costs over time due to wear and potential efficiency loss.

-

Vane Pumps: Despite a higher initial cost, vane pumps often offer lower long-term operational costs. Their self-compensating vanes and smooth operation can lead to reduced maintenance needs and longer service life.

Maintenance Considerations

-

Gear Pumps: Require less frequent maintenance but may experience a gradual decline in efficiency due to gear wear.

-

Vane Pumps: Benefit from design features that allow for easier maintenance and potential cost savings over time.

Typical Applications

Vane Pumps

Vane pumps are renowned for their versatility in handling low to medium-viscosity fluids across various industries. Their ability to maintain consistent flow rates and handle delicate fluids makes them suitable for applications such as:

-

Automotive Systems: Used in power steering, automatic transmission fluids, and brake systems, where consistent pressure and flow are essential for operational accuracy and safety.

-

Food and Beverage Processing: Employed to transfer products like oils, syrups, and concentrates, minimizing shear and maintaining the integrity of delicate products.

-

Pharmaceuticals: Utilized in tablet coating, vacuum filling of vials, and cream production, ensuring air-free conditions and contamination-free handling.

-

Chemical Industry: Ideal for transferring solvents, acids, and other chemicals, benefiting from the vane pump’s ability to handle corrosive materials when designed with appropriate materials.

-

Environmental Management: Used in applications like soil remediation and groundwater sampling, where creating a vacuum is necessary to extract samples or contaminants.

Gear Pumps

Gear pumps are favored for their robustness and efficiency in handling high-viscosity fluids and providing precise dosing in demanding environments. Their applications include:

-

Hydraulic Systems: Serving as the heart of countless applications across industries like construction, oil & gas, and manufacturing, gear pumps are integral to hydraulic systems due to their durability, efficiency, and reliability.

-

Chemical Processing: Widely used for pumping high-viscosity fluids such as oils, paints, resins, and foodstuffs, gear pumps are preferred in applications requiring accurate dosing or high-pressure output.

-

Food and Beverage Industry: Employed for transferring substances like chocolate, cacao butter, fillers, sugar, vegetable fats and oils, molasses, and animal food, gear pumps are suitable for handling various food products.

-

Petrochemical Industry: Utilized for transferring materials like pure or filled bitumen, pitch, diesel oil, crude oil, and lube oil, gear pumps are essential in the petrochemical sector.

-

Pulp and Paper Industry: Used for pumping substances such as acid, soap, lye, black liquor, kaolin, lime, latex, and sludge, gear pumps play a crucial role in the pulp and paper industry.

In summary, both vane and gear pumps offer distinct advantages tailored to specific operational needs. Vane pumps excel in applications requiring consistent flow and the handling of delicate fluids, while gear pumps are preferred for their robustness and efficiency in managing high-viscosity fluids and providing precise dosing.

For industries seeking a reliable and versatile hydraulic solutions provider, Poocca Hydraulic (Shenzhen) Co., Ltd. stands out as a reputable choice. Established in 2006, Poocca boasts over 18 years of experience in the hydraulic industry, specializing in the design, manufacturing, and maintenance of hydraulic pumps, motors, valves, and accessories.

Post time: Sep-06-2025