Micro gear pumps are specialized hydraulic devices designed to transfer precise volumes of fluid in a controlled and reliable manner. Unlike standard gear pumps, micro gear pumps are compact in size, allowing them to fit seamlessly into tight spaces and small-scale hydraulic systems. Their unique design ensures accurate flow rates, making them essential in applications that demand high precision, such as medical equipment, laboratory automation, and industrial lubrication systems.

These pumps operate with minimal noise and vibration, delivering smooth performance even under continuous operation. Their robust construction and durable materials make them capable of handling a variety of fluid types, including oils, fuels, and certain chemicals.

As industries increasingly seek solutions that combine efficiency, accuracy, and reliability, micro gear pumps have become a critical component in many small-scale hydraulic and dosing systems. Selecting the right micro gear pump can significantly impact system performance, energy efficiency, and overall operational longevity.

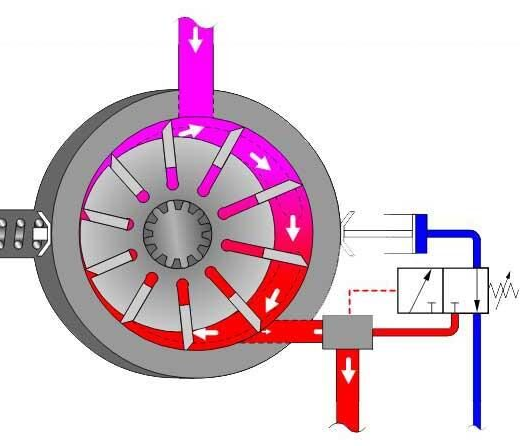

How Micro Gear Pumps Work

Micro gear pumps are positive displacement pumps that move fluid using two meshing gears inside a compact casing. As the gears rotate, fluid is trapped between the teeth and the casing, transferring it from the inlet to the outlet with high precision.

Their small size allows for accurate flow control and stable operation, even with different fluid viscosities. Micro gear pumps are durable, quiet, and produce minimal pulsation, making them ideal for applications that require precise and reliable fluid delivery.

Advantages of Micro Gear Pumps

Micro gear pumps offer several key advantages that make them indispensable in precision fluid applications:

-

High Accuracy and Precision:

- The positive displacement design ensures consistent flow rates, essential for dosing, lubrication, and laboratory systems.

-

Compact and Space-Saving:

- Their small footprint allows integration into tight assemblies and mobile equipment without compromising performance.

-

Durability and Reliability:

- Constructed from hardened metals or engineered polymers, micro gear pumps resist wear and provide long service life.

-

Versatility with Fluids:

- Suitable for a wide range of liquid viscosities, including oils, fuels, and certain chemicals.

-

Quiet and Smooth Operation:

- Low noise and minimal pulsation reduce vibration, protecting connected equipment and improving overall system longevity.

These advantages make micro gear pumps a superior choice over other small-scale pumps, especially when precise, reliable, and long-lasting performance is required.

Applications of Micro Gear Pumps

Micro gear pumps are widely used in industries where precise fluid control and compact design are essential. Common applications include:

-

Medical and Laboratory Equipment:

- Infusion pumps, diagnostic analyzers, and automated lab instruments require highly accurate fluid dosing, which micro gear pumps provide.

-

Industrial Lubrication Systems:

- Small machinery and automated equipment often rely on micro gear pumps to deliver consistent lubrication, ensuring smooth operation and reduced wear.

-

Chemical and Fuel Dosing:

- Micro gear pumps are ideal for transferring small volumes of chemicals, fuels, or other liquids where precision and reliability are critical.

-

Compact Hydraulic Systems:

- Mobile or space-constrained hydraulic equipment benefits from the pump’s small footprint without sacrificing performance.

These pumps are preferred whenever accuracy, durability, and compactness are required. Selecting a high-quality micro gear pump ensures stable operation, low maintenance, and long service life.

Choosing the Right Micro Gear Pump

Selecting the appropriate micro gear pump is critical to ensure reliable performance and long-term efficiency. Here are the main factors to consider:

-

Flow Rate and Pressure Requirements:

- Determine the required fluid volume and operating pressure. Micro gear pumps are ideal for low-flow, moderate-pressure applications where precision is key.

-

Fluid Type and Viscosity:

- Consider the type of liquid being pumped—oils, fuels, chemicals, or other fluids—and ensure the pump materials are compatible.

-

System Environment:

- Evaluate installation space, temperature range, and any exposure to harsh conditions. The compact design of micro gear pumps makes them suitable for confined or mobile systems.

-

Quality and Manufacturer Reputation:

- Opting for a reliable manufacturer ensures consistent performance, longer lifespan, and easier sourcing of spare parts.

By carefully assessing these factors, engineers and procurement professionals can choose a micro gear pump that delivers optimal precision, durability, and efficiency for their specific application.

Micro gear pumps are essential components for applications that demand precision, reliability, and compact design. Their ability to deliver consistent flow rates, handle a variety of fluids, and operate quietly makes them ideal for medical devices, industrial lubrication, chemical dosing, and compact hydraulic systems.

When selecting a micro gear pump, it’s important to consider flow rate, pressure, fluid type, and installation environment to ensure optimal performance. Choosing a reputable manufacturer also guarantees durability, ease of maintenance, and access to quality spare parts.

Several leading brands in the micro gear pump market include Parker, Marzocchi, Casappa, and Hyer, each known for high-quality engineering and reliability. For customers seeking a cost-effective yet dependable alternative, Poocca offers premium micro gear pumps that combine precision, durability, and competitive pricing, making them a trusted choice for OEMs and industrial applications alike.

Post time: Aug-29-2025