In many modern hydraulic systems, engineers and machine builders face a persistent dilemma: how to deliver both high flow for fast motion and high pressure for powerful work, without compromising on size, energy efficiency, or cost. Traditional single-stage gear pumps often force a trade-off: size the pump for peak pressure and suffer in low-load, low-pressure phases — or optimize for flow and end up over-powering the system when force is needed.

To address this problem, the two-stage gear pump was developed. Two-stage gear pumps (sometimes also called “high/low” or “dual-mode” gear pumps) are designed to provide rapid drive under light loads and high drive force when resistance increases, all integrated into a compact unit.

What Is a 2-Stage Gear Pump

A 2-stage gear pump combines two internal gear chambers — one optimized for high flow at low pressure, and the other for low flow at high pressure — within a single housing. This enables automatic switching between “fast” and “force” modes without the need for two separate pumps.

Definition & Concept

-

Unlike variable-displacement pumps that continuously modulate flow, a 2-stage gear pump provides two discrete operating states, enabled by internal valves that respond to system pressure.

-

The switching action is automatic: when system pressure is low, both chambers may contribute; as pressure climbs, an unloading mechanism engages, shifting load to the high-pressure (small displacement) stage.

Internal Structure

-

Gear Chambers: The pump contains two gear sets:

-

A large-displacement gear set for the low-pressure (high-flow) stage.

-

A smaller-displacement gear set for the high-pressure (low-flow) stage.

-

-

Displacement Ratio: The relative size of the chambers defines how much flow “drops off” when switching from low-pressure to high-pressure mode.

-

Switching / Unloading Valve: An internal valve (often an unloader) detects rising system pressure and reroutes or unloads the low-pressure chamber so the high-pressure chamber takes over.

Operation: Two Distinct Stages

-

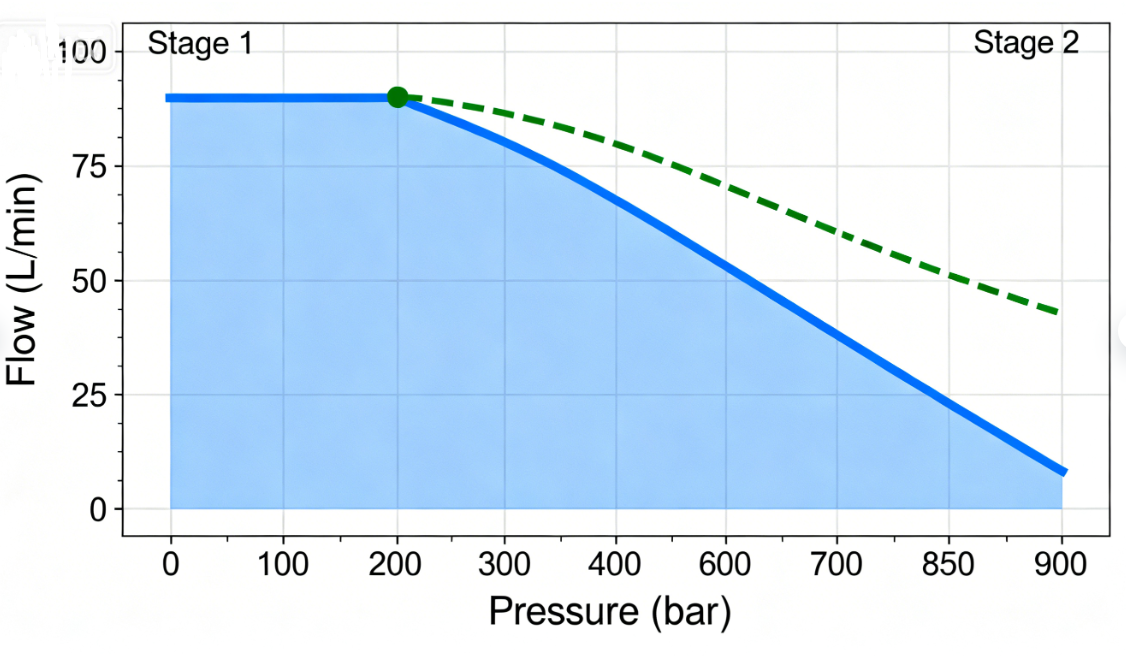

Stage 1 – Low Pressure (High Flow): During actuator extension or light load, the pump delivers maximum flow from the large chamber at moderate pressure. This enables fast motion, minimizing cycle time and reducing energy wasted in high-pressure mode.

-

Transition / Switching: As system pressure rises, the unloader valve activates, diverting or unloading the flow from the low-pressure stage. This allows the smaller high-pressure gear set to become the dominant flow contributor.

-

Stage 2 – High Pressure (Low Flow): Once switched, the high-pressure stage supplies fluid at high pressure (often up to several thousand psi) but lower flow, delivering force for work (e.g., splitting wood, pressing).

Performance Characteristics & Curve

-

The flow-vs-pressure curve typically shows a plateau of high flow at low pressure, followed by a drop as the pump transitions to high-pressure mode, and then a reduced but constant flow at high pressure.

-

The transition (unloading) pressure is a key design parameter: it must be carefully set to match the system’s load profile for smooth operation.

-

Manufacturing precision (tolerances, side-plate design, seal quality) strongly influences how cleanly the pump switches, how much internal leakage there is, and the overall efficiency in both modes.

Comparison: 2-Stage vs Other Pump Types

2-Stage vs Single-Stage Gear Pump

-

Efficiency Under Variable Load: Single-stage gear pumps deliver a fixed displacement for each revolution, but in many systems, the actual required flow varies widely. A 2-stage pump avoids inefficiencies by operating in its low-pressure mode when high flow is needed but high pressure is not — then switching to high pressure only when necessary.

-

Power Consumption: Because the high-pressure chamber only dominates when needed, the drive motor or engine can often be sized smaller than for a single-stage pump that must always deliver maximum pressure.

-

Component Stress and Wear: Running a single-stage pump continuously at high pressure can stress internal components (gears, bearings, seals). A 2-stage pump, by contrast, spends much of its cycle at moderate pressure, reducing wear.

-

System Simplicity vs Complexity: While two separate pumps might achieve similar behavior, a single 2-stage pump reduces plumbing, reduces part count, and simplifies the overall hydraulic circuit.

2-Stage vs Variable-Displacement (Piston) Pumps

-

Control & Precision: Variable-displacement piston pumps offer precise control of flow and pressure, but they are typically more expensive, more complex, and require control systems.

-

Cost-Effectiveness: For many cyclic applications (like log splitters or presses), 2-stage gear pumps provide a “sweet spot” — combining significant energy efficiency with lower cost than high-end variable pumps.

-

Reliability & Maintenance: Gear pumps are mechanically simpler and often more robust in harsh environments compared to variable-displacement piston pumps, which have more moving parts and higher sensitivity to contamination.

-

Efficiency in Duty Cycles: When load cycles alternate between high flow and high pressure, the 2-stage design is very efficient. Variable pumps can be highly efficient too, but often at the cost of more complex system design.

Energy Efficiency Analysis

-

By operating in low-pressure mode during the “fast” phase, a 2-stage pump can significantly reduce energy consumption, compared to a single-stage pump that runs at high pressure continuously.

-

In log splitters, for example, the high flow “approach” phase reduces cycle time, while the high-pressure “work” phase only engages when needed.

-

The design of the switch pressure, and precise calibration, is critical: if the transition point is poorly matched, efficiency gains may be lost, or worse, the system may experience pressure shock or instability.

Key Performance Metrics & Engineering Insights

Critical Technical Parameters

-

Flow / Displacement: Both low-stage (cc/rev or GPM) and high-stage displacement must be considered. For example, a model from Flowfit provides 16 GPM at 3600 RPM with a low-stage displacement of ~4.2 cc/rev and a high-stage of ~13 cc/rev.

-

Maximum Pressure: High-stage maximum pressure must meet system peak requirements. Many log-splitter style pumps rate up to 3,000 psi.

-

Switch (Unloading) Pressure: The pressure at which the pump shifts from low-pressure to high-pressure mode. Ideally adjustable or calibratable at commissioning.

-

Shaft Speed (RPM): Many 2-stage gear pumps can run at high speed (e.g., MTE pumps rated at up to 3,800–4,000 RPM).

-

Efficiency / Leakage: Volumetric efficiency depends heavily on internal leakage (slip), especially cross-stage leakage. Tight tolerances and good sealing are critical.

-

Materials & Construction: Durable materials in the housing, gears, and side-plates (e.g., cast iron, aluminum) help reliability. Poocca designs target high precision to minimize internal losses.

Reliability & Lifetime Considerations

-

Switching Frequency: Every transition between low and high mode induces cyclic stress on internal valves and gear sets. High-frequency switching can lead to fatigue if not well designed.

-

Internal Leakage (Slip): Over time, wear can increase internal clearances, leading to reduced volumetric efficiency.

-

Gear & Seal Wear: High-pressure operation is more demanding on gears and seals, particularly side-plates and O-rings.

-

Efficiency Degradation: As tolerances loosen or parts wear, efficiency may decline, increasing energy consumption or reducing performance.

-

Material Fatigue: Repeated high-pressure operation may fatigue components over a long period; material selection and design help mitigate this.

Risk & Failure Mode Analysis

Here are common risks associated with 2-stage gear pumps — and how to mitigate them:

| Risk | Possible Cause | Mitigation |

|---|---|---|

| Cross-stage leakage | Worn or loose internal tolerances, poor seal design | Use high-precision machining; maintain tight clearances; choose robust seal materials |

| Pressure shock / switching transients | Incorrect switch pressure or slow valve response | Calibrate unloading valve during commissioning; validate switching behavior |

| Fatigue failure | High switching frequency, cyclic stress | Select fatigue-resistant materials; limit high-pressure duty cycles; schedule inspections |

| Efficiency drop (cavitation / slip) | High RPM or poor inlet conditions | Design proper suction plumbing; maintain inlet pressure; monitor for cavitation |

| Seal / gear wear | Contaminated fluid, prolonged high-pressure use | Implement robust filtration, regular maintenance, seal replacements |

Maintenance & Calibration Best Practices

-

Switch Pressure Calibration: During installation or commissioning, perform a bench test to fine-tune the unloading pressure to match your system’s load signature.

-

Regular Inspection: Periodically check seals, side plates, and the unloading valve for wear, leakage, or drift in switch behavior.

-

Fluid & Filtration: Use clean, recommended hydraulic fluid. Contaminants accelerate wear and negatively affect switching.

-

Monitoring: Track temperature, vibration, and noise to catch early signs of wear or failure.

-

Spare Parts Strategy: Maintain a stock of critical spares (seals, valve parts, side plates) and implement a preventive maintenance schedule.

Total Cost of Ownership (TCO)

When evaluating a 2-stage gear pump, consider not just the sticker price, but lifetime cost:

-

CapEx (Capital Cost): Pump unit, mounting, drive system.

-

OpEx (Operating Cost): Energy consumption — a 2-stage pump can be significantly more efficient in cyclic applications.

-

Maintenance Cost: Seal replacements, switch calibration, inspections.

-

Downtime Cost: Potential production impact if switching fails or pump degrades.

-

Lifecycle Value: A properly specified and maintained 2-stage pump may outperform over its lifespan compared to simpler or more complex alternatives, especially in cyclic workloads.

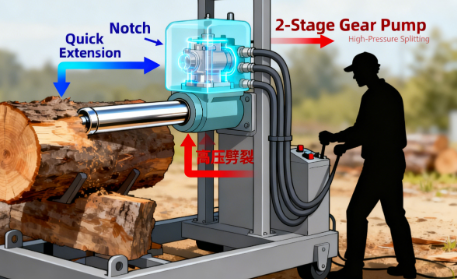

Primary Applications & Use Cases

2-Stage gear pumps are particularly effective in applications that benefit from a “fast approach, then high-pressure work” cycle. Here are some of the most common and impactful use cases.

Log Splitters

-

Cycle Profile: Extend the cylinder rapidly (low resistance), then apply high pressure to split the log.

-

Why 2-Stage Works: The pump delivers high-flow in phase one, then automatically shifts to high-pressure mode when resistance is encountered, maximizing both speed and force.

-

Design Tips: Calibrate the unloading pressure to trigger just when the log is contacted; ensure proper suction design to avoid cavitation.

-

Value: Shorter cycle times, reduced engine power requirement, and more efficient fuel or energy usage.

Presses & Clamps

-

Use Case: Industrial presses, clamping machines, or assembly systems that require fast positioning and then strong force.

-

Advantages: Saves energy by only engaging high-pressure mode during the pressing or clamping phase. Reduces system complexity by eliminating the need for a separate high-pressure pump.

-

Implementation Guidance: Select a low-pressure displacement that supports fast motion, then size the high-pressure chamber to deliver the required clamping force.

Mobile Hydraulics (Construction, Agricultural, Lifting)

-

Scenarios: Loaders, agricultural implements, small cranes, mobile platforms.

-

Benefits: Space- and weight-efficient — replace two pumps with one. High energy efficiency: during transit or low-load operations, the pump works in low-pressure mode; under load, it seamlessly transitions.

-

Integration: OEMs should include 2-stage pump considerations early in machine architecture, matching drive motor or engine speed, torque, and load profile.

Advantages, Risks & Trade-offs

Key Advantages

-

Compactness & Integration: One unit handles both high flow and high pressure; reduces plumbing and parts.

-

Energy Efficiency: By operating in low-pressure mode much of the time, a 2-stage pump reduces waste and lowers load on the drive source.

-

Performance Flexibility: Provides dual-mode behavior (fast motion + force) without needing two separate pumps.

-

Lifecycle Benefits: Less time under full high pressure can reduce wear, leading to longer service life when properly maintained.

Challenges & Risks

-

Manufacturing Precision: Tight tolerances are needed, increasing complexity and cost.

-

Internal Leakage (Cross-Stage): Poorly designed clearances or seals can degrade efficiency.

-

Switching Shock / Transients: If the unloading valve or switch point is not well set, pressure spikes may harm the system.

-

Maintenance Complexity: Over time, internal wear may require disassembly and calibration.

-

Inlet Sensitivity: Requires good suction design to avoid cavitation or starved inlet, which would impair performance.

Trade-off Strategy

-

Use a 2-stage pump when your system has distinct phases (fast + heavy work).

-

Carefully define and tune the switch pressure according to the load profile.

-

Design your suction and filtration systems to avoid inlet issues.

-

Plan maintenance (calibration, seal inspection) from the start.

-

Work closely with a trusted manufacturer (like Poocca) to leverage custom configurations and ensure reliability.

How to Choose the Right 2-Stage Gear Pump

Here’s a structured guide to help you select the correct 2-stage gear pump for your application, from both a technical and practical perspective.

-

Define Flow Requirements:

-

Estimate flow (GPM or L/min) needed during your “fast” phase — such as actuator extension or motion.

-

Determine flow needed during the “work” phase (when force is applied).

-

-

Set Pressure Requirements:

-

Identify your system’s maximum working pressure.

-

Decide on an appropriate switch (unloading) pressure that lets the pump transition smoothly without over-pressurizing your system.

-

-

Mechanical Interface:

-

Confirm shaft size, coupling type, and rotation direction.

-

Check port sizes, flange design, and mounting configuration.

-

-

Drive Matching:

-

Choose a motor or engine that delivers the required RPM and torque in both modes.

-

Factor in efficiency; since the pump is more efficient in low-pressure mode, you might select a more compact driver.

-

-

Fluid & Filtration:

-

Use hydraulic fluid with proper viscosity and cleanliness.

-

Install quality filtration to protect internal components and preserve tight tolerances.

-

-

Maintenance Planning:

-

Include calibration of switch pressure in your commissioning plan.

-

Set up a maintenance schedule for seal checks, internal inspections, and part replacement.

-

-

Cost Evaluation:

-

Calculate total cost of ownership (TCO): initial cost + energy + maintenance + downtime.

-

Compare with single-stage and variable-displacement options to ensure the 2-stage pump offers real value for your application.

-

Common Misconceptions & Technical Q&A

Misconceptions

-

“Gear pumps can only run in one pressure mode.” Not true — 2-stage gear pumps have been designed precisely to switch between low-flow/high-flow and high-pressure modes.

-

“More complexity means less reliability.” While the internal structure is more complex, precision design and quality manufacture (as Poocca employs) can make 2-stage pumps very reliable.

-

“Leakage isn’t a big deal.” Internal (cross-stage) leakage can significantly reduce efficiency unless the pump is built with tight tolerances and good sealing.

-

“Switching pressure can be set arbitrarily.” Poorly set switch pressures can cause pressure spikes, inefficient transitions, or premature wear. Calibration is critical.

-

“Only gear pumps can deliver high pressure.” Variable pumps can deliver high pressure, but 2-stage gear pumps uniquely balance high flow, high pressure, and efficiency in dual-phase systems.

Technical Q&A

-

Q: Do I need a relief valve or unloader when using a 2-stage pump?

A: Yes. To protect the system and the pump, an unloader or properly tuned relief valve is essential. Without it, the high-pressure chamber can run into a “dead head,” stressing components. -

Q: How sensitive is the pump to suction conditions?

A: Very sensitive. Poor suction (cavitation or starved inlet) can degrade performance, increase noise, and shorten pump life. Proper reservoir design and inlet plumbing are crucial. -

Q: Does leakage always increase with pressure?

A: Generally yes. Higher pressures mean more potential for internal leakage, especially if tolerances grow with wear. That’s why precision and maintenance matter. -

Q: How often should I inspect or recalibrate the unloading valve?

A: It depends on usage. In systems with frequent switching, consider checking every few hundred hours to ensure stable switch behavior and performance. -

Q: Can I run a 2-stage pump at very high RPM?

A: You can — but be cautious. High RPM can increase internal leakage, heat, and wear. Ensure your design accommodates proper inlet conditions and cooling.

Conclusion & Call to Action

Conclusion

2-Stage gear pumps offer an elegant, efficient, and powerful solution for hydraulic systems that demand both fast motion and high-pressure force. By combining a high-flow chamber for speed with a high-pressure chamber for force, these pumps eliminate the need for dual-pump setups, simplify system design, and reduce energy consumption. When properly specified, manufactured, and maintained, they deliver excellent performance and long-term value.

Call to Action

If your application involves cyclic loads, fast actuation followed by high-force demands (such as log splitters, presses, mobile hydraulic machines, or OEM systems), consider how a Poocca 2-Stage Gear Pump could transform performance — and reduce your total cost of ownership.

Contact Poocca today for a free consultation: our engineers can help you size the right pump, tune the switch pressure, design for long-term reliability, and implement a maintenance plan tailored to your needs. Let us help you build a hydraulic system that’s faster, stronger, and smarter.

Post time: Nov-20-2025